Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

What should buyers pay attention to when choosing wear resistant ceramic liner

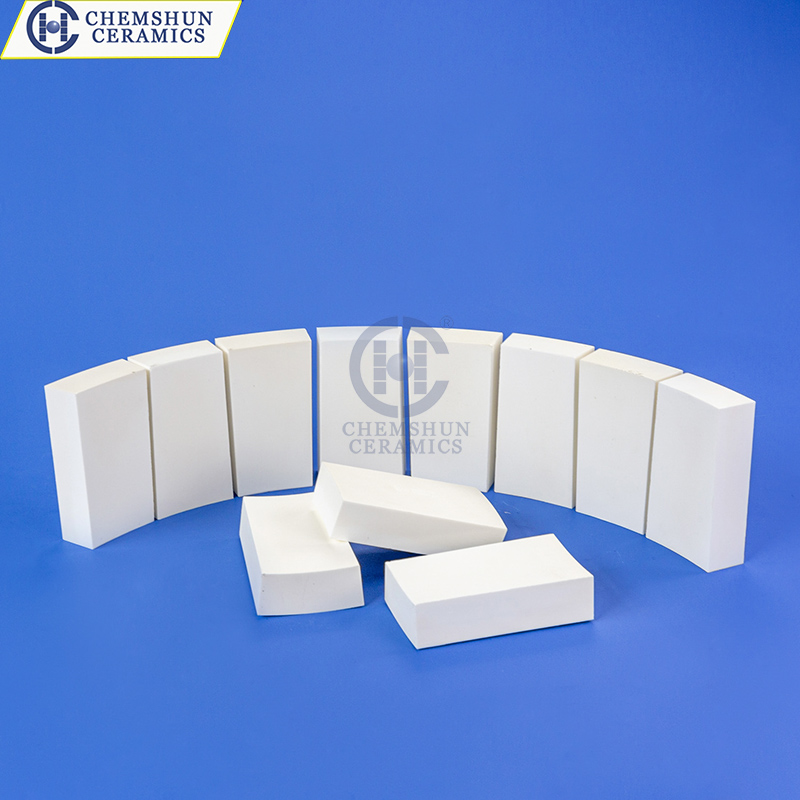

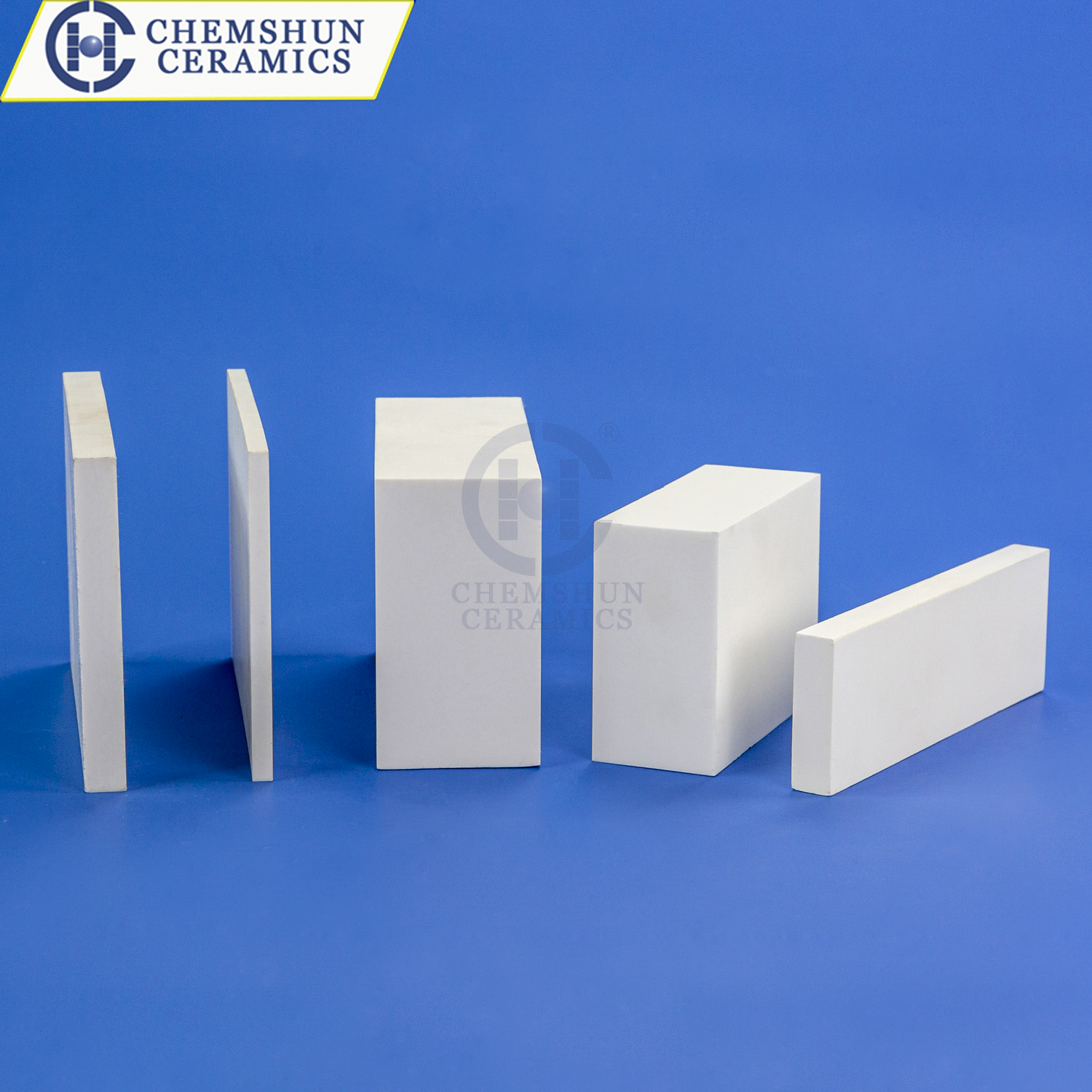

Wear-resistant ceramic liner is a kind of ceramic material used to enhance the wear resistance of equipment. It is made of alumina as raw material, plus other ingredients, and is fired at a high temperature of 1700 Degree Celsius. Wear-resistant ceramics are widely used in thermal power, iron and steel, smelting, machinery, coal, mining, chemical, cement, port and other enterprises of coal transport, feed system, powder system, ash discharge, dust removal system and all wear large mechanical equipment, can be selected according to different needs of different types of products.

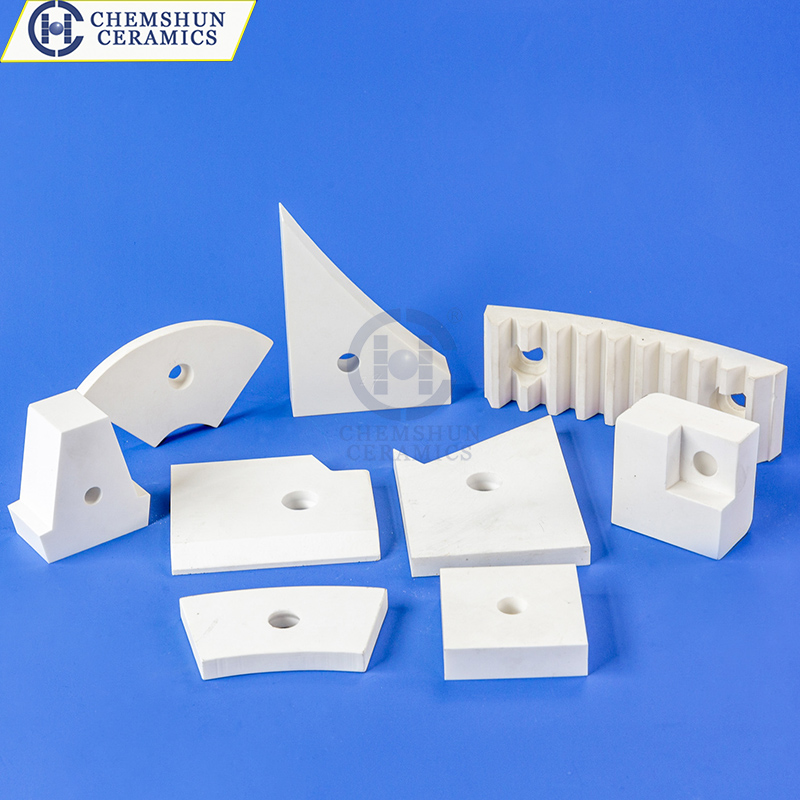

When choosing to use wear-resistant ceramic liner, it is necessary to consider its use environment and working conditions, as well as the size and aluminum content of the equipment. Here are some factors to consider:

1.Use environment: wear-resistant ceramic liner usually has high corrosion resistance and wear resistance, so it is very useful in some harsh environments (such as chemical, cement, mining, etc.). However, factors such as temperature, humidity, and corrosive substances in the environment will affect the performance and service life of the liner. Therefore, these factors need to be taken into account when selecting the liner.

2.Working conditions: Working conditions include the operating speed, pressure, impact force and other factors of the equipment. Different working conditions require the choice of different hardness and strength of the liner. For example, in high-impact environments, it may be necessary to choose a stiffer and impact-resistant liner.

3.Size: The size of the wear-resistant ceramic liner is usually determined according to the size of the equipment. Choosing the right size ensures that the liner will fully cover the surface of the equipment.

4.Aluminum content: Aluminum content is an important parameter of wear-resistant ceramic liner, which will affect the hardness, wear resistance and thermal stability of the liner. In some specific applications, it may be necessary to select a liner with a specific aluminum content. However, the choice of aluminum content is also affected by the equipment environment and working conditions, and needs to be selected according to the actual situation.

The choice of suitable wear-resistant ceramic liner needs to consider the use of environment, working conditions, size and aluminum content and other factors. In order to meet the operating requirements of the equipment, you may need to seek the help of a professional to ensure that the most suitable liner is selected.