Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

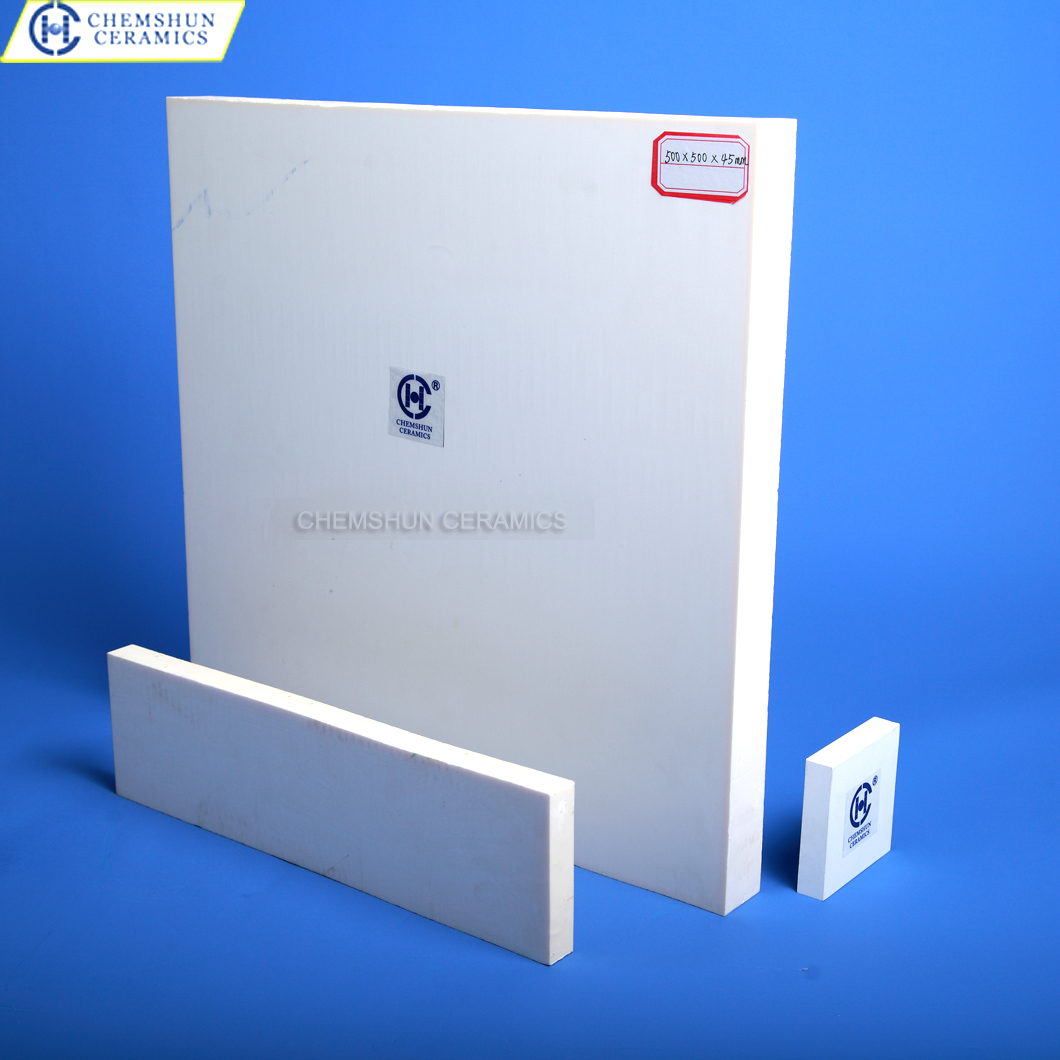

Seven aspects of advantages & applications of alumina ceramic substrates

Alumina ceramic substrates are a material with special advantages and are widely used in electronics, machinery, optics and other fields. The following will introduce the advantages and applications of alumina ceramic substrates from seven aspects.

First, alumina ceramic substrates have excellent thermal conductivity. Due to its high thermal conductivity (about 30~35W/m-K), alumina ceramic substrates can quickly transfer heat to the surrounding environment, thereby improving the heat dissipation capacity of electronic devices. Therefore, alumina ceramic substrates are often used as heat dissipation substrates for high-power electronic components, semiconductor devices, power modules, etc.

Secondly, alumina ceramic substrates have good insulation properties. Alumina ceramic substrates have high insulation resistance and breakdown voltage, which can effectively isolate various electronic components and protect them from external electromagnetic interference and charge accumulation. Therefore, alumina ceramic substrates are often used in high-frequency electronic devices, microwave equipment, high-voltage equipment, etc.

Third, alumina ceramic substrates have excellent chemical stability. Alumina ceramic substrates have good corrosion resistance and are not easily corroded by chemicals such as acids and alkalis. This makes alumina ceramic substrates widely used in the fields of chemistry and biotechnology, such as chemical reactors, biosensors, medical instruments, etc.

Fourth, alumina ceramic substrates have excellent mechanical properties. Alumina ceramic substrates have high hardness and strength, and can withstand greater pressure and impact. This makes alumina ceramic substrates widely used in mechanical processing, manufacturing and other fields, such as mechanical seals, abrasives, cutting tools, etc.

Fifth, alumina ceramic substrates have good stability. Alumina ceramic substrates can still maintain their stable performance in harsh environments such as high temperature and low temperature. Therefore, alumina ceramic substrates are often used in high-temperature electronic devices, high-temperature sensors, high-temperature reactors, etc.

Sixth, alumina ceramic substrates have excellent wear resistance and abrasion resistance. Due to a certain high hardness, alumina ceramic substrates can withstand external forces such as friction and wear, and are not easy to wear and break. Therefore, alumina ceramic substrates are widely used in friction materials, abrasives, ceramic tools and other fields.

Finally, alumina ceramic substrates have good optical properties. Alumina ceramic substrates have good light transmittance and reflectivity, and can effectively transmit and reflect light. Therefore, alumina ceramic substrates are often used as optical glass, optical light guide plates, laser devices, etc.