Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

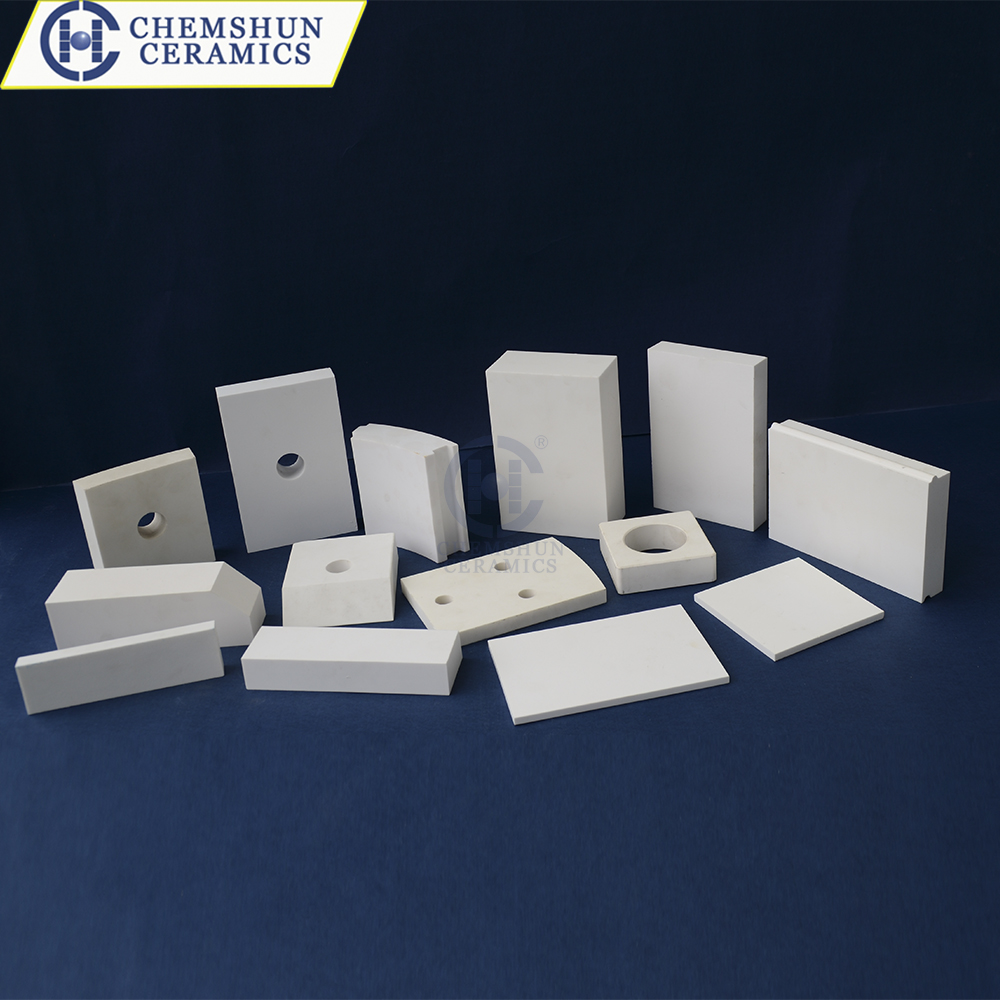

The mining industry faces severe challenges in equipment wear due to abrasive ores, high-impact environments, and corrosive conditions. Selecting the right wear-resistant ceramic lining tiles is critical to extending equipment lifespan, reducing maintenance costs, and improving operational efficiency. Below are key considerations for choosing suitable ceramic lining bricks in mining applications.

1. Application Scenarios and Wear Types

Different mining equipment faces varying wear mechanisms. For example:

Crushers and Grinders: High abrasion from ore crushing requires high-hardness alumina ceramics (Al2O3≥92%) to resist grinding wear.

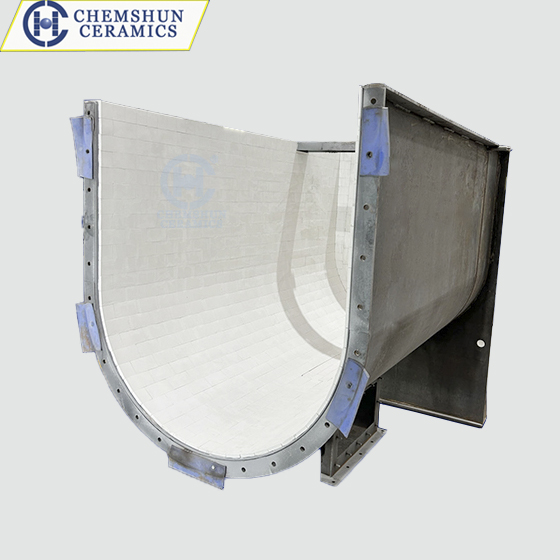

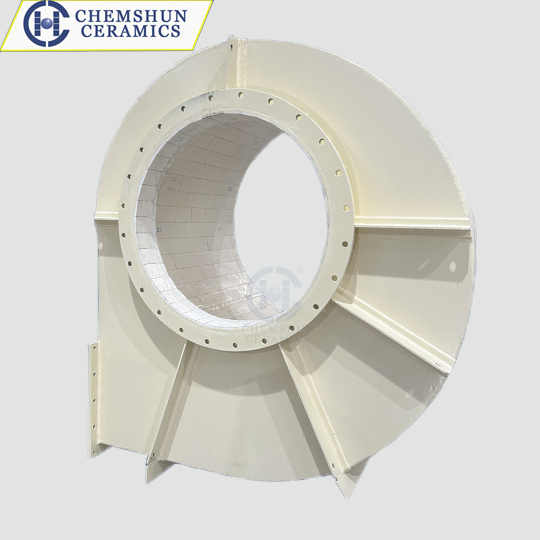

Chutes and Conveyor Belts: Impact wear dominates here, necessitating materials with high toughness, such as ZTA (Zirconia Toughened Alumina) ceramics or composite liners combining ceramics and rubber.

Ball Mill Cylinders: High-temperature and corrosion resistance are essential. Alumina ceramics with ≥95% purity or ZTA ceramics are recommended.

2. Material Properties and Performance

Hardness and Abrasion Resistance: Alumina ceramics (Mohs hardness 9) are ideal for abrasive environments, but their brittleness limits use in high-impact zones. ZTA ceramics, combining alumina and zirconia, offer enhanced toughness (3–4 times higher than pure alumina) while maintaining hardness, making them suitable for combined abrasion and impact conditions.

Thermal Stability: For high-temperature operations (e.g., near furnaces), select ceramics with low thermal expansion coefficients, such as ZTA or silicon carbide (SiC) ceramics.

Corrosion Resistance: In acidic or alkaline environments (e.g., mineral processing), high-purity alumina ceramics (≥95%) or chemically inert SiC ceramics are preferred.

3. Impact Resistance Optimization

In high-impact mining environments (e.g., ore dumping points):

Thickness and Size: Use thicker (≥60 mm) and larger ceramic blocks to avoid cracking at joints.

Composite Structures: Ceramic-rubber or ceramic-steel composite liners absorb impact energy while maintaining wear resistance. However, rubber composites are limited to temperatures below 80°C.

Surface Design: Ceramic tiles with convex surfaces (e.g., hemispherical protrusions) distribute impact forces more effectively.

4. Cost and Maintenance Considerations

Lifecycle Cost: While ZTA ceramics have higher upfront costs, their extended lifespan (2–3 times longer than alumina ceramics) reduces replacement frequency and downtime.

Ease of Installation: Prefabricated modular designs simplify installation and reduce labor costs.

5. Supplier Selection and Customization

Choose suppliers with proven expertise in mining applications. For example:

Technical Support: Ensure suppliers provide material testing.

Customization: Tailor ceramic thickness, size, and composition based on equipment specifications (e.g., ball mill diameter and operating pressure).

Selecting wear-resistant ceramic lining tiles in the mining industry requires a holistic analysis of wear mechanisms, material properties, and operational conditions.Partnering with specialized suppliers ensures optimal performance and cost efficiency. Pingxiang Chemshun Ceramics Co.,Ltd is a professional manufacturer of wear resistant ceramic liners,ceramic grinding media and wear protection provider.With more than 20 years experience of R&D/produce/independent quality control/site operation in the wear field.Cooperation with Chemshun,we’ll bring and increase value to you.