Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

When installing alumina ceramic liner, in order to ensure its long-term firm and not easy to fall off, it is necessary to adopt a scientific installation method based on specific conditions (such as temperature, vibration, impact, corrosion, etc.). The following installation steps and key measures are combined with actual working conditions:

1. Pre-Installation Preparations

Substrate Surface Treatment

Cleaning: Remove oil, rust, and dust from the equipment’s inner wall (via sandblasting or grinding to Sa2.5 cleanliness).

Flatness: Ensure the substrate surface is even, with irregularities ≤2mm to prevent localized stress concentration.

Drying: For high-humidity environments, pre-dry the surface to avoid adhesive failure.

Liner Pre-Treatment

Inspect liners for cracks or defects; clean the backside (if adhesive bonding is used).

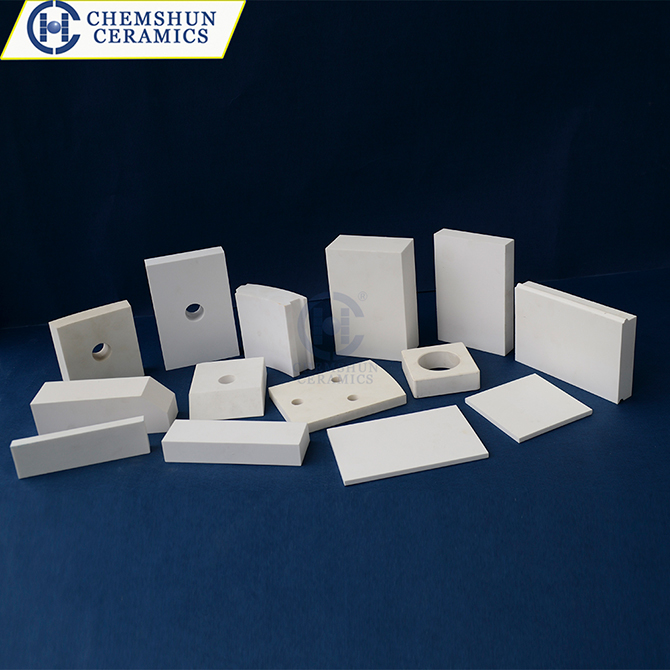

Select liner types based on working conditions:

Bolted liners: Suitable for mechanical fixation.

Dovetail-grooved liners: Ideal for high-temperature or high-vibration environments.

Flat liners: Require high-strength adhesives.

2. Installation Methods (Adapt Based on Working Conditions)

Adhesive Bonding (For Non-High-Temperature, Low-Medium Impact Conditions)

Adhesive Selection: Epoxy resin (temperature ≤120°C, shear strength ≥15MPa); Silicone adhesive (temperature ≤300°C, flexible for vibration resistance); High-temperature inorganic adhesive (temperature ≥800°C, e.g., aluminum phosphate adhesive).

Key Steps:

Apply adhesive to both substrate and liner (0.5–1mm thickness).

Pressurize during curing (use clamps or sandbags for 24 hours).

Reserve 2–3mm thermal expansion gaps for high-temperature applications.

Welding Method (For High-Temperature, High-Impact Conditions)

Ceramic Anchor Fixation: Weld threaded steel plates to the substrate and secure liners with ceramic bolts (rated ≥600°C).

Dovetail Groove Welding: Engage pre-cast dovetail grooves on liners with welded steel strips on the substrate.Suitable for high-vibration equipment (e.g., mining ball mills).

Mechanical Fixation (For Heavy-Impact Equipment)

Bolting: Drill holes through liners and substrate; fasten with anti-loosening bolts and spring washers. Sink bolt heads below the liner surface to avoid material erosion.

Clamp Fixation: For pipelines, use stainless steel clamps with high-temperature gaskets to secure liners.

3.Solutions for Special Conditions

High Humidity/Corrosion: Coat substrates with zinc-rich epoxy primer; use acid/alkali-resistant adhesives (e.g., phenolic epoxy). Select 316L stainless steel bolts/clamps.

High-Vibration Equipment (e.g., Screens, Crushers): Combine adhesive bonding with mechanical fixation (e.g., bolts after adhesive curing). Or use flexible adhesives (e.g., polyurethane) to absorb vibration energy.

Extreme Temperatures (e.g., Cement Kilns): Fix liners with ceramic anchor pins and high-temperature adhesives (e.g., alumina-phosphate). Embed metal mesh on liner backsides to enhance mechanical interlock.

4. Post-Installation Inspection & Maintenance

Curing Verification:Perform tap testing to detect hollow areas (allowable hollow area<5%). Recheck bolt torque (e.g., 25–30N·m for M10 bolts).

Routine Maintenance: Inspect high-wear zones monthly (e.g., bends, inlets) and replace damaged liners promptly. Clear accumulated material from gaps to prevent liner warping.

By following these guidelines, ceramic liner adhesion and service life (typically 5–10 years) can be significantly enhanced. Tailor the combination of bonding, welding, and mechanical fixation to specific conditions, and rigorously control critical details.