Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

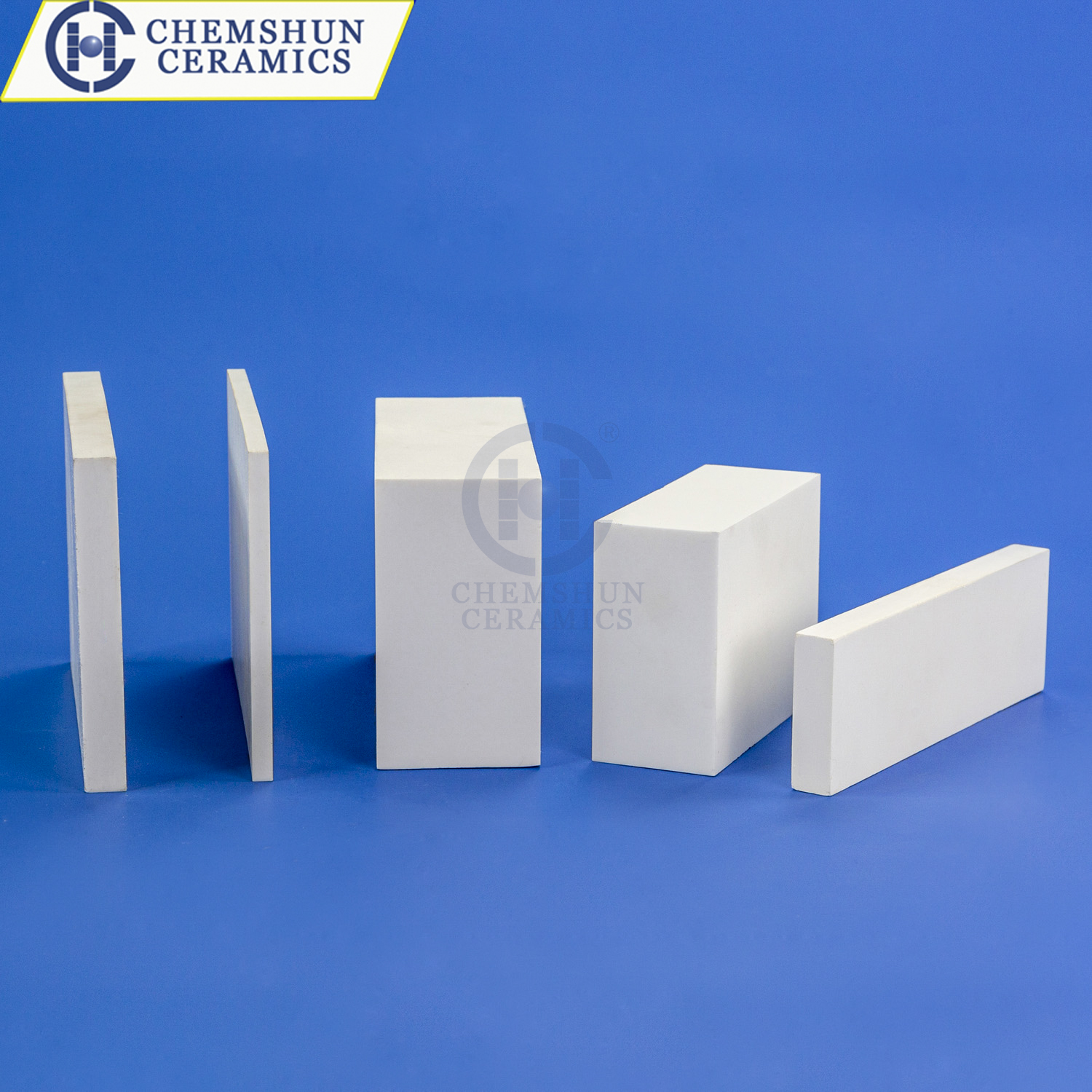

Alumina ceramic tiles are used in industrial equipment

In modern industry, the proportion of machinery and equipment used is relatively high. The daily load of the equipment is very large. When the equipment is used for a long time to transport materials, the equipment is continuously subjected to friction, which causes great damage to the equipment and affects the life of the machine. Delayed production, in order to make the equipment run normally, it is necessary to protect the machinery and equipment. The alumina ceramic tile becomes the protective umbrella of the machine. The wear-resistant ceramic tile is pasted in the equipment, which can withstand high temperature and wear, maintain the normal operation of the machine for a long time, and improve the equipment. Long lifespan, effectively reducing energy consumption, and conducive to the long-term development of the enterprise.

Alumina ceramic plain tiles have excellent corrosion and wear resistant property and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more. Ceramic tiles are adhered to equipment steel substrate with cement, epoxy etc. Protecting moving parts that are subject to high wear environments which is easy to install for end users.

Chemshun Ceramics supply wear resistant ceramic customized design , production,installation service . hope to help with your mechanical equipment wear damage .