Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

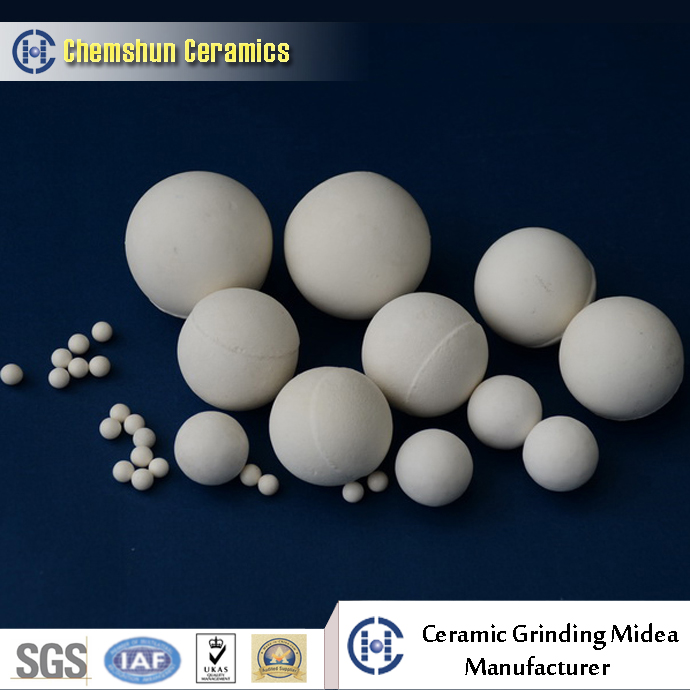

The mining industry can use high-strength alumina ceramic balls

The mining industry can use high-strength alumina ceramic balls. High strength alumina ceramic ball has the characteristics of high hardness, good wear resistance, corrosion resistance, good thermal stability, stable chemical properties, etc., so it is suitable for mine grinding. In the mine grinding process, the high-strength alumina ceramic ball can effectively reduce the contact area between the grinding medium and the ore, reduce the grinding power consumption, improve the grinding efficiency, and reduce the possibility of crushing the ore.

Alumina ceramics have good high temperature resistance and can keep its performance unchanged in high temperature environment. This gives ceramic balls an advantage when handling high-temperature mineral materials, as they can withstand higher temperatures without damage.

Alumina ceramics have stable chemistry and can resist the erosion of a variety of chemical substances. Alumina ceramic balls have advantages in handling corrosive mineral materials and will not be affected by corrosive materials.

In addition, the selection of the appropriate diameter and height ratio of high-strength alumina ceramic balls can increase the circulation of materials in the sphere, reduce the grinding rate, improve the fineness control accuracy, thereby improving the quality and recovery of minerals.

When using high-strength alumina ceramic balls for mine grinding, the following points need to be noted:

Proper installation and adjustment of the grinding equipment: Ensure that the ceramic ball is properly installed and adjusted in the grinding equipment to maximize its performance.

Regular inspection and replacement of ceramic balls: According to the use of the equipment and the degree of wear, regular inspection and replacement of ceramic balls to ensure the normal operation of the equipment and the efficiency of material grinding.

Pay attention to environmental protection: When using ceramic balls for mine grinding, it is necessary to pay attention to environmental protection issues. Ensure that the equipment does not produce excessive dust and noise during operation to reduce the impact on the environment.