Product Name:Alumina Wafer Polishing Plate

- Product Category:

- Product Details:

Chemshun Alumina Wafer Polishing Plate/Turn Table is high purity 99.7-99.9%Alumina Ceramic.It's shaped by PIBM. It is one of the semiconductor industry because of its incomparable thermal and dimensional stability,and the resistance to the sever microchip-processing equipment environment. - E-Mail:

Chemshun Alumina Wafer Polishing Plate/Turn Table is high purity 99.7-99.9%Alumina Ceramic.It's shaped by PIBM. It is one of the semiconductor industry

because of its incomparable thermal and dimensional stability,and the resistance to the sever microchip-processing equipment environment.

Application:

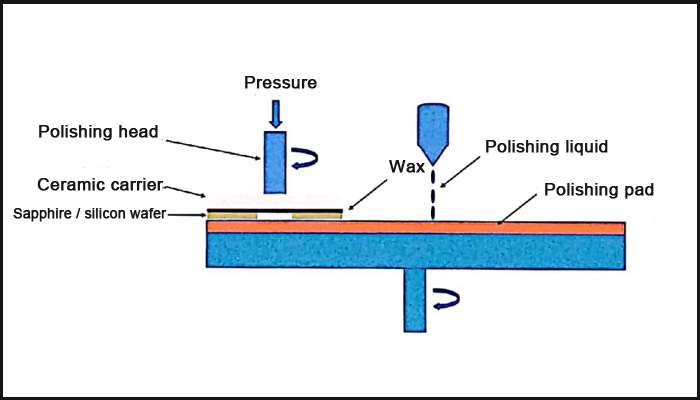

As an important component of CMP chemical mechanical polishing process. CMP is the necessary for producing process of the sapphire and Wafer.

Chemshun Ceramics' alumina ceramics sapphire lapping wafer polishing is shaped as PIBM producing process. Its an internaltional advanced technology. PIBM sucessful solve the key problem of crack and deformation of large size alumina ceramics.PIBM technology will open another window of fine ceramics. We not only produce the high quality alumina ceramic wafer polishing plate, but also other series of large size high purity alumina ceramics such as 1200x500x20mm ceramic substrates for LCD manufacturing equipment, semiconductor delviery tracks, vacuum parts, general mechanical parts, bulletproof ceramics.

Features :

High rigidity (Hardness, Mechanical Strength, Wear Resistance)

High chemical durability

Incomparable thermal

High purity and uniformity

Surface shape & roughness control

Pretty Price

Size:

Disc, ring size below ∅850mm, thickness 45mm.

For example: D150mm, D360mm,D 600mm.

Customized products with various size are accepted.

Main Parameter : (Chemical / physical):

Property | Item | Unit | Chemshun 99.7% Alumina Ceramics |

General Properties | Main component | wt% | 99.7-99.9 |

Density | gm/cc | 3.94-3.97 | |

Color | - | Ivory | |

Water absorption | % | 0 | |

Mechanical Properties | Flexural Strength(MOR) 20 ℃ | Mpa(psix10^3) | 440-550 |

Elastic Modulus 20℃ | GPa (psix10^6) | 375 | |

Vickers Hardness | Gpa(kg/mm2) R45N | >=17 | |

Bending Strength | Gpa | 390 | |

Tensile Strength 25℃ | MPa(psix10^3) | 248 | |

Fracture Toughness (K I c) | Mpa* m^1/2 | 4-5 | |

Thermal Properities | Thermal conductivity(20℃) | W/mk | 30 |

Coefficient of Thermal expansion(25-1000℃) | 1x 10^-6/℃ | 7.6 | |

Thermal Shock Resistance | ℃(? Tc) | 200 | |

Maximum use temperature | ℃ | 1700 | |

Electrical Properities | Dielectric Strength (1MHz) | ac-kv/mm(ac v/mil) | 8.7 |

Dielectric Constant(1 MHz) | 25℃ | 9.7 | |

Volume Resistivity | ohm-cm (25℃) | >10^14 | |

ohm-cm (500℃) | 2x10^12 | ||

ohm-cm (1000℃) | 2x10^7 |

Photo Reference:

Related Keywords :

Chemical Mechanical polishing (CMP) alumina ceramic Wafer Polishing Plate / Turn Table sapphire lapping| Company name: | Please fill in your company name |

| * E-mail: | |

| Source: |

|

| * Inquire intention description: | |

| Please fill in the quantity and description of Inquire products for uniform stocking. | |

CHEMSHUN Product

abrasion resistant ceramics

ZTA Ceramics ★★★★★

Zirconium Ceramics

Silicon Carbide Products

Ballistic Protective Ceramic

Ceramic pipe liner

engineering ceramics

ceramics lined equipment

rubber ceramic liner

Ceramic Grinding Media

- Alumina Grinding Ball & Cylinder

- Zirconia Ball/ Beads

- Zirconia Silica Grinding Beads

- Grinding Ball for Ceramics

- Mill Ceramic Bricks Liner

- Grinding Balls for Cement Mill

- Grinding Balls for Mining/ Mineral

99.7 Alumina Plate ★★★★★

Ceramic Rubber Hose

99 Alumina Tube

catalyst carrier

Foundry Ceramic Sand

Ceramic pump

Epoxy Resin Glue

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

ADD:Non-metal area of shangliuyuan, Economic development zone, pingxiang city, Jiangxi province, P.R.China

- comments in total【Write a Review】Customer Reviews