Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

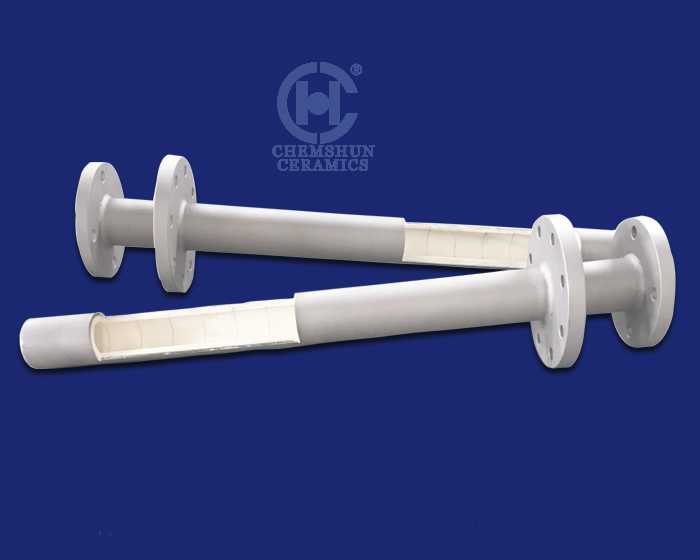

Wear-resistant ceramic tubes are used in the lithium battery transport industry

Wear-resistant ceramic pipe is a kind of high wear-resistant pipe with many excellent characteristics.

Wear-resistant ceramic pipes have good chemical stability, which can resist the corrosion of most chemical substances, including acids, alkalis, salts and other chemicals. This makes it particularly suitable for handling chemicals used in the production of lithium batteries, such as lithium salts and various organic and inorganic solutions.

The wear-resistant ceramic pipe has high hardness and good wear resistance, and can withstand the friction and impact in the battery production process. This can extend the service life of the pipe and reduce the cost of repair and maintenance.

Wear-resistant ceramic pipes can withstand high temperatures, and can resist the oxidation of most gases and liquids, and can be used in high temperature working environments.

Wear-resistant ceramic pipes are widely used in the transport industry of lithium batteries. In the production process of lithium batteries, wear-resistant ceramic pipes can be used to transport various materials and chemicals, such as battery paste, electrode paste, lithium salt, etc., which can effectively protect pipes and equipment, extend their service life, while reducing maintenance costs and reducing downtime.

In addition, wear-resistant ceramic pipes can also be used to treat waste water and waste gas in the production of lithium batteries, effectively reducing environmental pollution. Due to its high strength and corrosion resistance, wear-resistant ceramic pipes can withstand the erosion of various chemical substances and are not easy to break and clog, thus extending the service life.

In general, wear-resistant ceramic pipes have the advantages of high temperature resistance, chemical stability, high hardness, good wear resistance, and corrosion resistance, which make them widely used in the lithium battery industry. In the lithium battery production process, it can help protect the equipment from chemical corrosion, extend the service life of the equipment, and improve production efficiency.