Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Wear-resistant ceramics solve the problem of wear in the mining industry

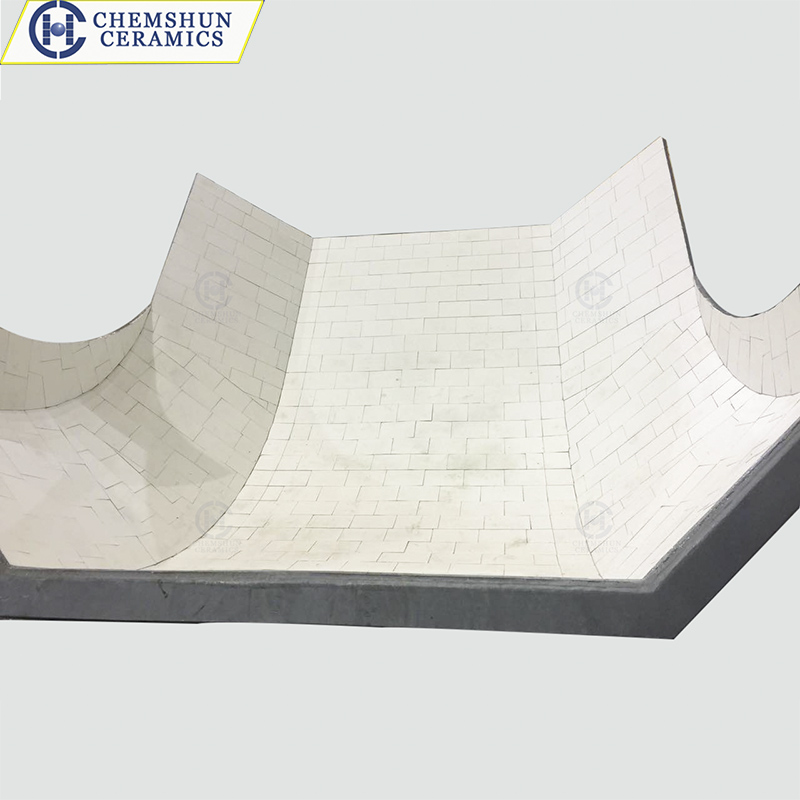

Wear problems in the mining industry can be solved by using wear-resistant ceramics. Wear-resistant ceramic is a kind of ceramic material with excellent wear-resistant properties, which has the characteristics of high hardness, high strength, corrosion resistance, high temperature resistance, etc., and is suitable for various working conditions.

Wear problems in the mining industry can be solved by using wear-resistant ceramics. Wear-resistant ceramic is a kind of ceramic material with excellent wear-resistant properties, which has the characteristics of high hardness, high strength, corrosion resistance, high temperature resistance, etc., and is suitable for various working conditions. Alumina ceramics, hardness up to more than HRA85, wear resistance than fierce steel 271.5 times; It has stable chemical properties and can be operated in a high temperature environment of 0℃-250℃ for a long time. In addition, wear-resistant ceramics can also resist acid and alkali corrosive substances, so it can also be used in the chemical industry.

In the mining industry, wear-resistant ceramics can be used in the following areas:

Mining equipment: wear-resistant ceramics can be applied to the key components of mining equipment, such as digging buckets, drills, drill pipes, etc., to improve the wear resistance of equipment, extend the service life of equipment, and reduce maintenance costs.

Conveying equipment: wear-resistant ceramics can be used for wear-resistant parts in conveying equipment, such as rollers of belt conveyor, brackets, etc., to improve the wear-resistant performance of equipment, reduce the wear and maintenance times of equipment, and improve production efficiency.

Conveying equipment: wear-resistant ceramics can be used for wear-resistant parts in conveying equipment, such as rollers of belt conveyor, brackets, etc., to improve the wear-resistant performance of equipment, reduce the wear and maintenance times of equipment, and improve production efficiency.

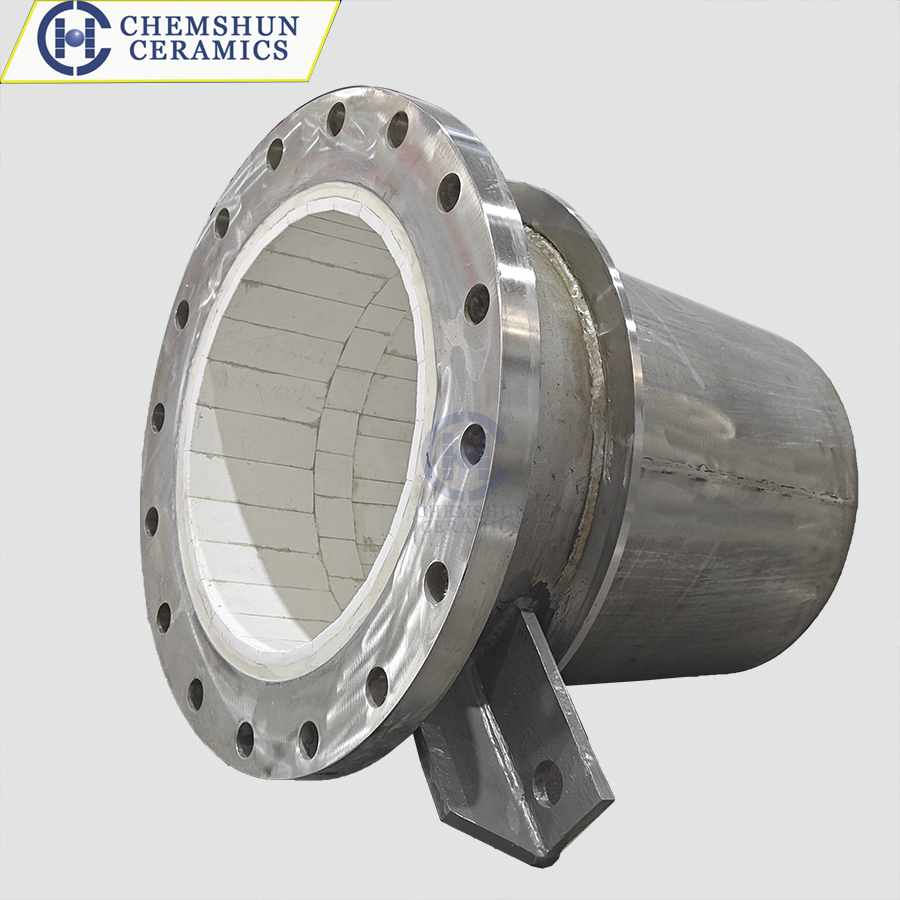

Pipeline system: wear-resistant ceramics can be used for wear-resistant parts in the mine pipeline system, such as pipe elbows, tees, valves, etc., to improve the wear-resistant performance of the pipeline system, extend the service life of the pipeline system, and reduce maintenance costs.

The use of wear-resistant ceramics can effectively solve the wear problem in the mining industry, improve the service life and production efficiency of equipment and systems, and reduce maintenance costs.