Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

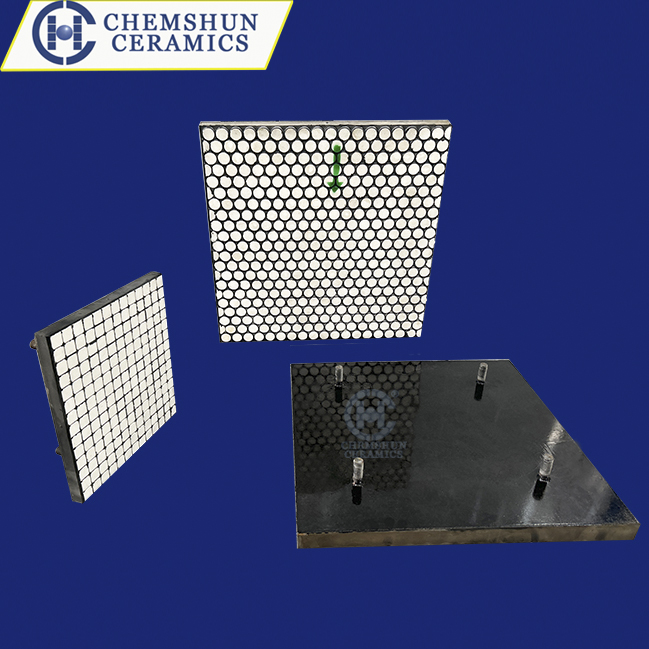

Wear-resistant ceramic rubber plate for port industry

Wear Resistant Rubber Ceramic Panels is made by a combination of wear resistant alumina ceramics (cylinders, hexagon, plates) vulcanized in resistant rubber base, some rubber plates can selectively with steel backing. The alumina ceramic provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Chemshun Alumina Oxide Ceramic Wear Plates have many sizes available .

Wear-resistant ceramic rubber composite panels have a variety of applications in ports, including but not limited to the following situations:

1. Non-slip: wear-resistant ceramic rubber composite plate surface is smooth, friction coefficient is small, not easy to slip, easy to move personnel and goods, enhance the efficiency and safety of the port.

2. Reduce noise: Due to the material of wear-resistant ceramic rubber composite board, it can effectively reduce the noise generated by mechanical equipment in the port area, which is especially important when dealing with port container handling, transport and other noisy work.

3. Anti-collision protection: When the goods are concentrated in the dock area, due to the impact and friction of containers and other goods, wear-resistant ceramic rubber composite board can provide effective anti-collision protection and extend the service life of port machinery and equipment.

4. Anti-corrosion: In some special environments, the port area may be affected by chemicals, resulting in damage to machinery and equipment. The wear-resistant ceramic rubber composite board has anti-corrosion properties and can extend the service life of the equipment.

5. Wear resistance: wear-resistant ceramic rubber composite plate has excellent wear resistance, can withstand the frequent friction and impact of mechanical equipment in the port area, and extend the service life of mechanical equipment.

6. High temperature resistance: In the process of port operation, mechanical equipment may encounter high temperature environment, wear-resistant ceramic rubber composite board has good high temperature resistance, can adapt to the special environment of the port.