Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

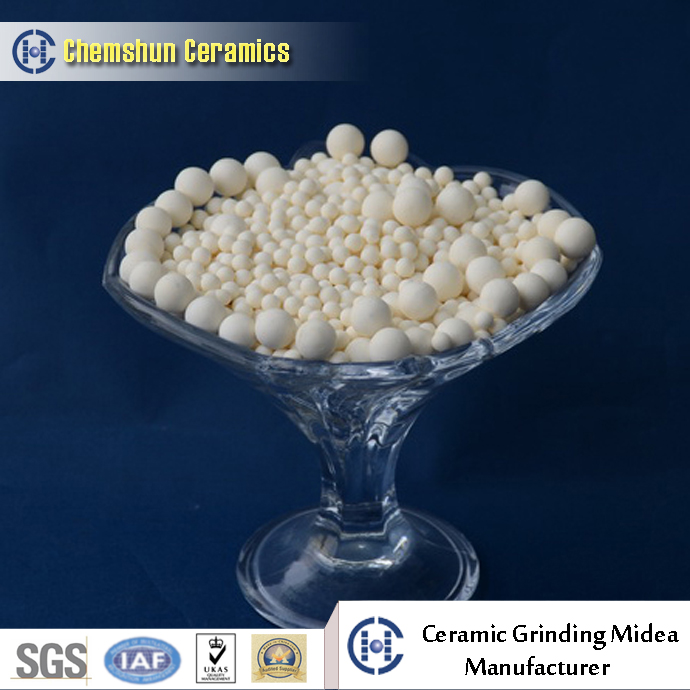

Alumina ceramic ball - high hardness grinding medium

Alumina ceramic ball is a spherical grinding medium made of alumina (Al2O3) powder, usually used in ceramics, glass, metal and other industries. It has high hardness and high wear resistance, which can effectively improve processing efficiency and quality.

Alumina ceramic balls have a wide range of applications, including ceramics, glass, metal and other industries. In the ceramic industry, alumina ceramic balls are often used in the manufacture of ceramic tools, sandblasting materials, ultra-fine grinding and so on. In addition, alumina ceramic balls can also be used in the glass industry for grinding and polishing glass products. In metal processing, alumina ceramic balls can be used in ultra-fine grinding processes to improve the finish and wear resistance of metal surfaces.

The characteristics of alumina ceramic balls include high hardness and high wear resistance, which can effectively improve the processing efficiency and quality of equipment. Usually used in metal materials, minerals and fine chemical products and other media wear, sealing and cutting grinding fields. At the same time, its strength and wear resistance can be adjusted according to the actual use requirements by changing the sintering process or adding modifiers.

In addition, alumina ceramic balls can also be customized according to performance requirements such as hardness, density, aperture and aperture uniformity parameters to meet the needs of different fields of application. It should be noted that when using alumina ceramic balls, appropriate installation, maintenance and maintenance need to be carried out according to different use environments and conditions to ensure its long-term stable working performance.