Top articles

- Wear-resistant Ceramic Sheets are Used for Anti-wear Lining of Pipes

- Alumina Ceramic Cylinder for Vulcanized in Wear Ceramic Rubber Liner

- High-purity Alumina Ceramic Wafer Polishing Plate

- Alumina ceramic tube - high quality wear-resistant ceramics

- Wear-resistant ceramics solve the problem of wear in the mining industry

- Wear-resistant ceramic tubes are used in the lithium battery transport industry

- Wear-resistant ceramic rubber plate for port industry

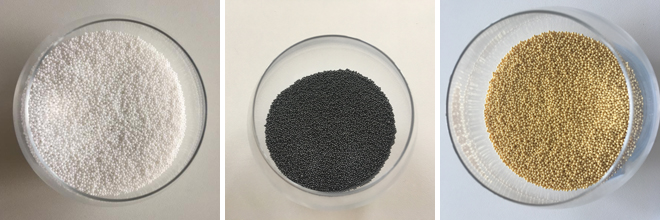

- Alumina ceramic ball - high hardness grinding medium

- How to prevent the wear damage of alumina ceramic chute liner during operation?

- How to improve the smoothness of the cut surface of alumina ceramics?

Latest articles

- Wear-resistant Ceramic Sheets are Used for Anti-wear Lining of Pipes

- Alumina Ceramic Cylinder for Vulcanized in Wear Ceramic Rubber Liner

- High-purity Alumina Ceramic Wafer Polishing Plate

- Alumina ceramic tube - high quality wear-resistant ceramics

- Wear-resistant ceramics solve the problem of wear in the mining industry

- Wear-resistant ceramic tubes are used in the lithium battery transport industry

- Wear-resistant ceramic rubber plate for port industry

- Alumina ceramic ball - high hardness grinding medium

- How to prevent the wear damage of alumina ceramic chute liner during operation?

- How to improve the smoothness of the cut surface of alumina ceramics?

Your browsing history

How to use ceramic grinding ball in ball mill of cement industry?

In order to reduce the crushing loss of ceramic grinding balls in cement ball mills, the following points should be paid attention to:

1. When loading the mill with empty warehouse, add materials first and then add the ceramic balls.

China's cement industry has been forced to eliminate the ball mill below 3 meters, so all enterprises in the grinding ball assembly mill, are using electric hoist, lifting and unloading, the drop is more than 3 meters. Ceramic grinding ball is discharged into the bin with cast steel lining plate, which will impact the lining plate and cause different degrees of micro-cracks inside the grinding ball, affecting the service life. Therefore, empty warehouse loading grinding should first add 2~3 tons of bulk cement, in order to ease the unloading.

2. Ceramic grinding ball should not be used in the first bin of ball mill.

Although most of the present cement grinding system adopts pre-crushing equipment, which reduces the particle size of the grinding material a lot, when the particle size of the grinding material is 25mm, the first bin of the ball mill still needs the grinding ball to be in the throwing state, mainly for impact crushing effect, crushing the bulk material into new "grains". At this point, the grinding ball is not only subjected to a strong "reaction force ", but also inevitably hit the mill inside the dense cast steel lining, compartments and other components. Therefore, such conditions are not suitable for ceramic grinding balls with limited toughness. Otherwise, a higher rate of breakage will occur.

3. Shorten the "empty material area" behind the silo board as much as possible.

The cement ball mill cylinder is equipped with a double compartment plate, the front layer is composed of a number of grate plate assembly, the second layer is composed of no grate slot blind plate and the center discharge cone (vent). The fine particles in the front bin can flow into the sandwich layer of the compartment through energy seam, and then pass through the back layer, which rises from the hoisting plate on the board and falls to the outer wall of the middle unloading cone and slides to the next bin (tail bin). The inner wall of the unloading cone is the central vent of the mill. Under the action of the wind speed in the mill, the fine particles falling from the outer wall of the unloading cone will be blown away, leaving a distance from the compartment plate to form a "grinding ball"· the "empty material area" with more and less materials directly affects the effective utilization rate of this warehouse. If this bin is filled with ceramic grinding ball, it will cause collision and wear between grinding ball, grinding ball and steel lining plate, shorten the service life of grinding ball, speed up the rate of broken ball. Therefore, before using ceramic grinding balls, increase the length of the feeder plate as much as possible to make it close to the cylinder, so that the fine particles entering the sandwich layer of the compartment can be quickly picked up and more materials fall into the next bin. At the same time, the central control operation can properly reduce the wind, reduce the central wind speed, shorten the length of "empty material area", reduce the "self-damage" loss of ceramic grinding ball, and increase the effective work.

4. Adjust operation habits to prevent "empty mill" operation.

When ball mill cement grinding system is used in steel ball and steel forging, it is a common operation habit to "add material after starting empty grinding and stop grinding after discharging empty material". However, using ceramic grinding balls, these habits become the most common "killer" of "broken balls". The collision and friction between porcelain ball and steel lining plate will produce numerous micro-cracks, which will accelerate the expansion of cracks and finally lead to grinding ball cracking. Porcelain ball cracked surface, like a sharp edge, split to other grinding ball, no material block and buffer, cause grinding ball more extensive damage, a "ball war" will quickly spread.

Pay attention to the above points, the efficiency of your ball mill will be greatly improved and the cost will be reduced. For more information about the application of ceramic grinding balls please feel free to contact with us: office@chemshun.com, tel:+86-799-6790781, what's app: +86-158-79957696.