Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

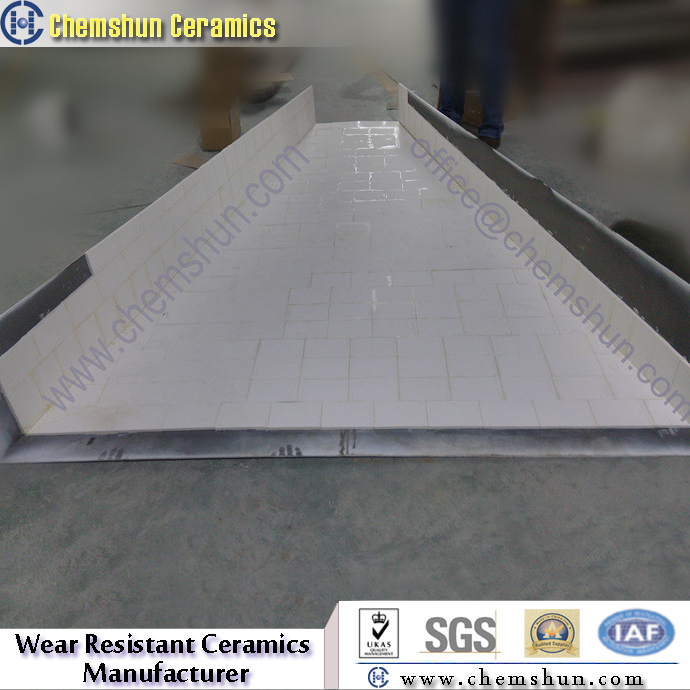

How to prevent the wear damage of alumina ceramic chute liner during operation?

Alumina ceramic tile liner installed as chute lining is much widely applied in bulk material handling system for wear protection .In order to prevent the wear damage of alumina ceramic chute linerduring operation, the following measures can be taken for better wear protection.

1. Select suitable alumina ceramic materials: Ensure that alumina ceramic materials with high wear resistance, corrosion resistance and impact resistance are selected to adapt to the harsh working environment of the mine.

2. Optimize chute design: Rationally design the structure and size of the chute to reduce the impact and friction of materials in the chute and reduce the wear rate.

3. Control material properties: Try to control the composition, particle size and humidity of the material to avoid mixing too many impurities or large pieces of material into the material to reduce the wear of the alumina ceramic chute.

4. Regular inspection and maintenance: Regularly inspect the alumina ceramic chute to promptly detect and repair worn parts. For severely worn parts, they can be repaired or replaced.

5. Reasonable operation and management: When operating the alumina ceramic chute, the operating procedures should be followed to avoid excessive impact and vibration. At the same time, strengthen the daily management and maintenance of the equipment to ensure the normal operation of the equipment.

6. Take lubrication measures: Apply appropriate lubricants to key parts of the alumina ceramic chute to reduce friction and wear.

7. Carry out technical upgrades: According to actual needs, the alumina ceramic chute is technically upgraded, such as using new wear-resistant materials, optimizing structural design, etc., to improve its wear resistance and service life.

Through the comprehensive application of the above measures, the wear of the alumina ceramic chute during operation can be effectively prevented, and its working efficiency and service life can be improved. At the same time, attention should also be paid to regular evaluation and maintenance of the performance of the alumina ceramic chute to ensure its long-term stable operation.