Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

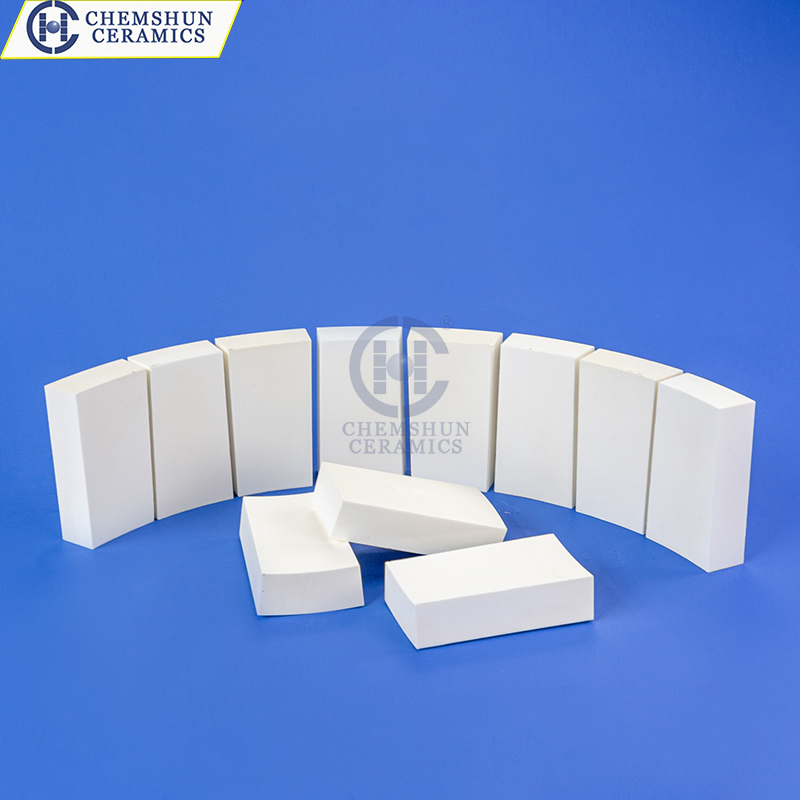

Wear-resistant ceramics are used in cement industry

Wear-resistant ceramics are widely used in cement industry. For example, wear-resistant ceramic sheets, wear-resistant ceramic pipes, ceramic balls, wear-resistant ceramic lining and other products are widely used in cement plants, power plants, mining and other industries, which often need to transport materials with certain wear.

Wear-resistant ceramics show good wear resistance, corrosion resistance and high temperature resistance in these applications, which can effectively extend the service life of equipment and reduce the frequency of replacement parts, thereby reducing production costs. In addition, the chemical properties of wear-resistant ceramics are stable, and it is not easy to react with the material, ensuring the normal operation of the equipment.

In the cement industry, the application field of wear-resistant ceramics also includes rotary kiln, powder separator, cyclone separator, elevator and other equipment, as well as pipeline, chute, wear-resistant joint and other pipeline equipment. These devices are subject to wear and corrosion during long-term use, so wear-resistant materials are needed to extend their service life.

When the ceramic ball is used instead of the steel ball on the cement mill, the noise can be reduced, the vibration can be reduced, and the grinding efficiency can be improved. The use of ceramic lining on the vertical mill can also achieve good results, which not only extends the service life of the equipment, reduces the maintenance workload and maintenance costs, but also reduces the friction coefficient between the material and the roller, and reduces the occurrence of the bonding phenomenon of the material on the roller.

In general, the application of wear-resistant ceramics in the cement industry has improved production efficiency and product quality, and reduced costs and maintenance workload. However, when using wear-resistant ceramics, it is necessary to pay attention to its corrosion resistance and high temperature resistance to ensure its stability and reliability during use.