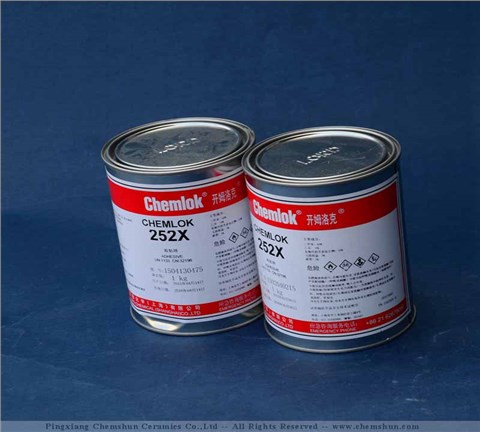

Chemlok Glue for vulcanization (252X)

1: Application

Widely make all kinds of rubber and metal substrate meterials glued togeter by hot vulcanization .Rubber includes natural rubber, polyisoprene rubber, styrene-butadiene rubber, butadiene rubber, neoprene, nitrile rubber,butyl rubber and EPDM rubber.; substrate: carbon steel. Steel, stainless steel. aluminum. copper. Copper alloys, magnesium and zinc and other metals as well as plastics and textile fibers.

2: Chemlok Glue property:

1) Appearance : Black liquid

2) Viscosity: 250 cps (Brookfield LVT, 2 # rotor, 30 rev / min, 25 ℃).

3) Solid content: 22.0 to 24.0% (by weight)

4) Density : 0.953 ~ 0.989

5) Shelf life: at the end of open container (25 ℃) 12 months

3: Instructions for use

1) Surface treatment: mechanical method (blasting) degreasing, or chemical treatment.

2) Dilution: direct coating may be diluted. If the actual operational needs, it

can also be diluted with an appropriate amount of the aforementioned diluent.

3) Mixing: The thoroughly stirred prior to coating, to achieve uniform mixing before use.

4) Coating: by brushing or roll coating. Dipping. Transfer method CH252X uniformly coated on the substrate surface metal.

5) Glue dry film thickness :( dry) 12 ~ 25u, bonding vulcanized rubber

6) Drying: drying at room temperature at least 45 minutes

7) Parking: vulcanization immediately after drying if necessary, it can be parked for a long time, but to avoid contamination.

8) Cure: Depending on the vulcanization condition of materials

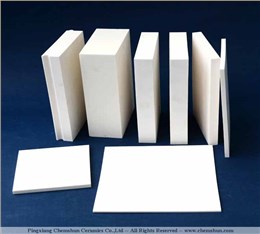

Ceramic Tile Liner

Ceramic Tile Liner Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner Curved Pipe Tile Liner

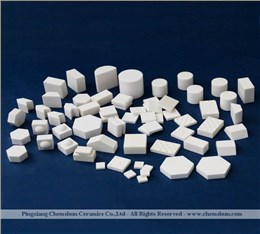

Curved Pipe Tile Liner Trapezoidal Pipe Tile

Trapezoidal Pipe Tile 90 degree pipe elbow

90 degree pipe elbow Cyclone Pipe Liner

Cyclone Pipe Liner 92% Aluminium Oxide Pipe Ring

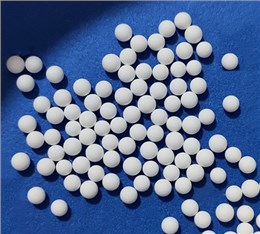

92% Aluminium Oxide Pipe Ring 92% High Alumina Grinding Ball

92% High Alumina Grinding Ball Ceramic Liner With Salient Point

Ceramic Liner With Salient Point Alumina Cylinder

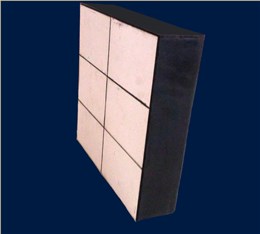

Alumina Cylinder Ceramic Rubber Composite Liner

Ceramic Rubber Composite Liner Ceramic Epoxy Resin Glue

Ceramic Epoxy Resin Glue Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner Zirconia Ceramic Beads

Zirconia Ceramic Beads Hex Rubber Ceramic Wear Plate

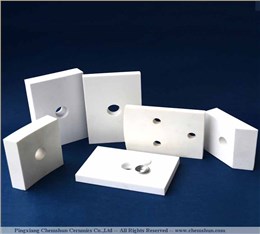

Hex Rubber Ceramic Wear Plate 95% Alumina Engineering Ceramics

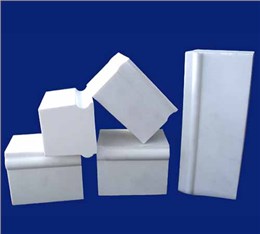

95% Alumina Engineering Ceramics Alumina Ceramic Block

Alumina Ceramic Block Square Lagging Ceramics

Square Lagging Ceramics Alumina Ceramics Lined Hopper

Alumina Ceramics Lined Hopper Ceramic Lined Pipe

Ceramic Lined Pipe Pulley Lagging Ceramics

Pulley Lagging Ceramics Technical Ceramics

Technical Ceramics Square Ceramic Rubber Component

Square Ceramic Rubber Component Weldable alumina tile

Weldable alumina tile Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Rubber backed alumina ceramic tiles

Rubber backed alumina ceramic tiles AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Engineered Ceramic Lined Pipe

Engineered Ceramic Lined Pipe Yttria-stabilized zirconia grinding beads

Yttria-stabilized zirconia grinding beads Mining Ceramic Grinding Balls

Mining Ceramic Grinding Balls Cement Mill Grinding Ball

Cement Mill Grinding Ball Ceramic Rubber Hose

Ceramic Rubber Hose Dove-Tailor Ceramic Liner

Dove-Tailor Ceramic Liner 95% Grinding Cylinder

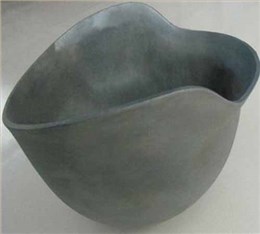

95% Grinding Cylinder Ceramic Cone

Ceramic Cone Customized Technical Ceramics

Customized Technical Ceramics Alumina Tube

Alumina Tube Alumina Ceramics bricks

Alumina Ceramics bricks Abrasion Advanced Ceramics

Abrasion Advanced Ceramics Hexagonal Alumina Tile

Hexagonal Alumina Tile Ceramic Cyclone Liner

Ceramic Cyclone Liner Cutting Ceramic Tile

Cutting Ceramic Tile Curved Pipe Liner

Curved Pipe Liner Ceramic Chute Liner

Ceramic Chute Liner Stock Bin

Stock Bin Coking Plant

Coking Plant Mill Bricks Liner

Mill Bricks Liner SIC Cyclone

SIC Cyclone Silicon Carbide Bulletproof Tiles

Silicon Carbide Bulletproof Tiles Ceramic Lining Glue 8280

Ceramic Lining Glue 8280