Silicon Carbide Bulletproof Tiles

Reaction sintered Silicon Carbide Bulletproof Tiles is widely used in mining, ore crushing, screening and high wear and corrosion fluid material conveying.Silicon carbide steel shell lined with products, due to its good abrasion resistance and corrosion resistance, is suitable for conveying powder, slurry, widely used in mining, mineral processing and power plants and other industries.

Silicon carbide parts (SiC), also known as carborundum, is a compound of silicon and carbon with a chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics which are widely used in applications requiring high endurance, such as car brakes and ceramic plates in bulletproof vests. Electronic applications of silicon carbide as light emitting diode and detector in early radios have been demonstrated around 1907, and nowadayscorrosion-resistant ceramicsinteredSiC is widely used in high-temperature semiconductor electronics. Large single crystals of ceramic silicon carbide can be grown by the Lely method; they can be cut into gems known as "synthetic moissanite". Silicon carbide with high surface area can be produced from SiO2 contained in plant material

2. Key Features of Sintered Silicon Carbideceramic armor plates

1). High temperature tolerance,temperature up to 1600

2). Wear resistance

3). Corrosion resistance

4). High bending strength

5). high hardness

6).light weight

7).oxidation resistance

8).perfect efficiency of sealing

9).long time service life

10).Heat shock stability

11). Highly performance of mechanical strength

12).Cleaning or etching the hardest sub-surfaces

13).Used for grinding, lapping, and wire saw cutting as well as abrasive blasting

14).Self-lubrication

15).Lower thermal expansion coefficient

16). High thermal conductivity

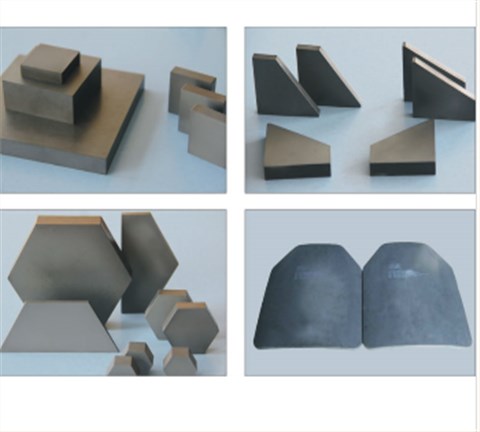

17).All shape customized, can be square, hexagonal, cylindrical,or disc-like etc.

18). It is manufactured by pressureless sintering.or Reaction-Bonding

3. Applications:

Body Armor Plates /hexagon sic silicon carbide ceramic armor plate

High-Tech Vehicle Armor Protection and Watercraft defence.

4. Specifications:

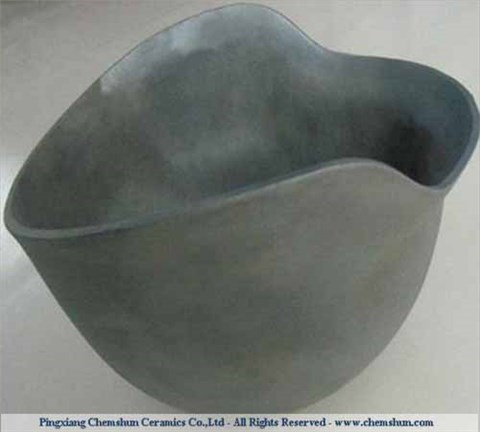

Name: bulletproof plate (single curve)

Material: SiC ceramic

Protection level: NIJ 0101.04 Level III (Stand alone)

Size: 10*12 (250mm*300mm)

Weight: 2.4kg

With waterproof cover

USA NIJ 0101.04 STANDARD

Class | Test-bullet | Bullet Weight | Bullet Velocity | Distance | Max. BFD | No. of Shots | No. of Test |

I | .22 Caliber LR | 2.6 | 329+-9 | 5 | 44 | 6 | 4 |

.380 ACP | 6.2 | 322+-9 | 5 | 44 | 6 | 4 | |

II-A | 9mm | 8.0 | 341+-9 | 5 | 44 | 6 | 4 |

.40S&W | 11.7 | 322+-9 | 5 | 44 | 6 | 4 | |

II | 9mm | 8.0 | 367+-9 | 5 | 44 | 6 | 4 |

.357 Mag | 10.2 | 436+-9 | 5 | 44 | 6 | 4 | |

III-A | 9mm | 8.2 | 436+-9 | 5 | 44 | 6 | 4 |

.44 Mag | 15.6 | 436+-9 | 5 | 44 | 6 | 4 | |

III | 7.62mm Nato | 9.6 | 847+-9 | 15 | 44 | 6 | 2 |

IV | .30 Calier | 10.8 | 878+-9 | 15 | 44 | 1 | 2 |

5. Technical data

Properties | Units | RSiC | SiSiC | SSiC |

Bulk denstity SiC | Vo1% | ≥99 | ≥85 | ≥99 |

Bulk density | g/cm3 | 2.60~2.72 | 3.01 | 3.10-3.15 |

Apparent porosity | % | 15 | <0.1 | <0.2 |

Modulus of rupture at 20℃ | Mpa | 80~90 | 250 | 400 |

Modulus of rupture at 1200℃ | Mpa | 90~100 | 280 | 650 |

Modulus of elasticity at 20℃ | Gpa | - | 330 | 410 |

Thermal Conductivity at 1200℃ | w.m-1.k-1 | 35.0 | 45 | 55 |

Thermal expansion at 1200℃ | a×10-6/℃ | 4.60 | 4.5 | 4.0 |

Thermal shock resistance at 1200℃ | Very good | Very good | Very good | |

Max.working temperature | ℃ | 1650(oxid) | 1350 | 1600 |

Service:

Any requirment about chemshun Alumina Ceramic Square Mosaic Tile ,Silicon CarbideBulletproof Tiles, Wear Ceramic Liner Vulcanized Into Rubber and wear resistant ceramic product Backing, alumina ceramic rubber wear plate and Wear Resistant Rubber Ceramic Panels, please feel free contact us and chemshun we'll afford you the most suitable product and best service. web:www.chemshun.com . Tel:86-799-6790781

Export:

Our products have been exported to many countries: Australia, Chile, USA, Russia, UK, Indonesia, etc., good quality have be approved by our clients.

Ceramic Tile Liner

Ceramic Tile Liner Weldable alumina tile

Weldable alumina tile Curved Pipe Tile Liner

Curved Pipe Tile Liner Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Trapezoidal Pipe Tile

Trapezoidal Pipe Tile 90 degree pipe elbow

90 degree pipe elbow Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner (SISIC) Silicon Carbide Ceramic Plate

(SISIC) Silicon Carbide Ceramic Plate Cyclone Pipe Liner

Cyclone Pipe Liner 92% Aluminium Oxide Pipe Ring

92% Aluminium Oxide Pipe Ring 92% High Alumina Grinding Ball

92% High Alumina Grinding Ball Ceramic Liner With Salient Point

Ceramic Liner With Salient Point Alumina Cylinder

Alumina Cylinder Ceramic Rubber Composite Liner

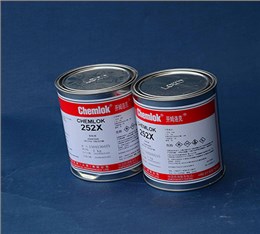

Ceramic Rubber Composite Liner Ceramic Epoxy Resin Glue

Ceramic Epoxy Resin Glue Zirconia Ceramic Beads

Zirconia Ceramic Beads Hex Rubber Ceramic Wear Plate

Hex Rubber Ceramic Wear Plate 95% Alumina Engineering Ceramics

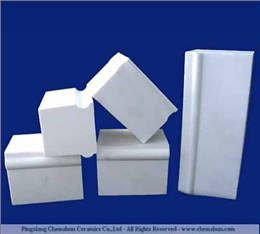

95% Alumina Engineering Ceramics Alumina Ceramic Block

Alumina Ceramic Block Square Ceramic Tile

Square Ceramic Tile Alumina Ceramics Lined Hopper

Alumina Ceramics Lined Hopper Ceramic Lined Pipe

Ceramic Lined Pipe Pulley Lagging Ceramics

Pulley Lagging Ceramics Technical Ceramics

Technical Ceramics Square Ceramic Rubber Component

Square Ceramic Rubber Component Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Rubber backed alumina ceramic tiles

Rubber backed alumina ceramic tiles Engineered Ceramic Lined Pipe

Engineered Ceramic Lined Pipe SSIC Ceramic Seal Ring

SSIC Ceramic Seal Ring SSIC Ceramic Grinding Barrel Cylinder

SSIC Ceramic Grinding Barrel Cylinder Yttria-stabilized zirconia grinding beads

Yttria-stabilized zirconia grinding beads Mining Ceramic Grinding Balls

Mining Ceramic Grinding Balls Cement Mill Grinding Ball

Cement Mill Grinding Ball Ceramic Rubber Hose

Ceramic Rubber Hose Chemlok Glue For Vulcanization (252X)

Chemlok Glue For Vulcanization (252X) Dove-Tailor Ceramic Liner

Dove-Tailor Ceramic Liner 95% Grinding Cylinder

95% Grinding Cylinder Ceramic Cone

Ceramic Cone Customized Technical Ceramics

Customized Technical Ceramics Alumina Tube

Alumina Tube Alumina Ceramics bricks

Alumina Ceramics bricks Abrasion Advanced Ceramics

Abrasion Advanced Ceramics Hexagonal Alumina Tile

Hexagonal Alumina Tile Ceramic Cyclone Liner

Ceramic Cyclone Liner Cutting Ceramic Tile

Cutting Ceramic Tile Curved Pipe Liner

Curved Pipe Liner Ceramic Chute Liner

Ceramic Chute Liner Stock Bin

Stock Bin Coking Plant

Coking Plant Mill Bricks Liner

Mill Bricks Liner SIC Cyclone

SIC Cyclone Ceramic Lining Glue 8280

Ceramic Lining Glue 8280