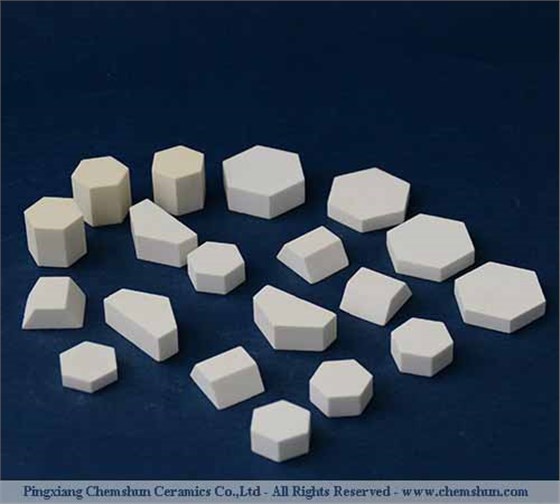

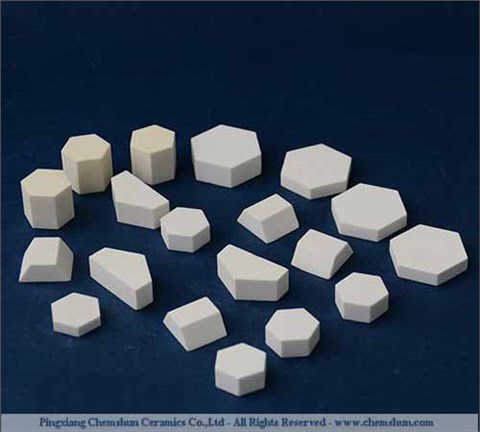

Hexagonal Alumina Tile![]()

Hexagonal Alumina tile widely used for hot vulcanized rubber ceramic component liner and pulley laggings ceramics.

Chemshun hexagonal alumina tile is used as lining with the advantage of wear-resisting, impact-resisting, easy operation, etc., is ideal surface wear-resisting material of material transfer equipment in iron & steel works, thermal & power plants, mine, etc. Wear-resistant lining Trades and can extend the operating life of equipment effectively. It is widely used as a tile mat lining in conveying engineering to protect the belts in the mining industry and agriculture, etc.

Raw Material:

The alumina wear resistance ceramic and wear ceramic liners products are made from the high purity, super fine and single narrow particle high-quality grain alumina powder, which is spray-dried processing, formed by cold isostatic pressing, firing on 1520 º C~1650 º C temperature. Subject to Al2O3 content difference, we have 92% or 95% alumina ceramics.

Advantage of the material:

1) High hardness: Its Rockwell hardness is HRA80-90 and the Moh's hardness is up to 9 grade with is only less than diamond. And its abrasion-resistant is better than steel and stainless steel;

2) Superior Abrasion-resistance: Its abrasion-resistance is 171.5 times of Chrome steel and 260 times of manganese steel materials and as per our customers' feedback, it could prolong the use life of equipment for more than 10years under same working conditions.

3) Light weight. Its density is 3.6-3.75g/cm3, it is only half the weight of steel and could reduce the load on equipment.

Product Technical Data(1:wear resistant ceramic)

Chemshun Ceramics also recommends these other Alumina Lining Pieces:

Ceramic Tile Liner

Ceramic Tile Liner Weldable alumina tile

Weldable alumina tile Curved Pipe Tile Liner

Curved Pipe Tile Liner Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Trapezoidal Pipe Tile

Trapezoidal Pipe Tile 90 degree pipe elbow

90 degree pipe elbow Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner (SISIC) Silicon Carbide Ceramic Plate

(SISIC) Silicon Carbide Ceramic Plate Cyclone Pipe Liner

Cyclone Pipe Liner 92% Aluminium Oxide Pipe Ring

92% Aluminium Oxide Pipe Ring 92% High Alumina Grinding Ball

92% High Alumina Grinding Ball Ceramic Liner With Salient Point

Ceramic Liner With Salient Point Alumina Cylinder

Alumina Cylinder Ceramic Rubber Composite Liner

Ceramic Rubber Composite Liner Ceramic Epoxy Resin Glue

Ceramic Epoxy Resin Glue Zirconia Ceramic Beads

Zirconia Ceramic Beads Hex Rubber Ceramic Wear Plate

Hex Rubber Ceramic Wear Plate 95% Alumina Engineering Ceramics

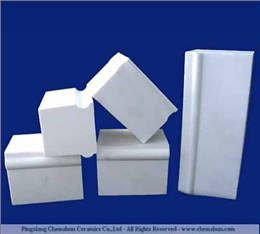

95% Alumina Engineering Ceramics Alumina Ceramic Block

Alumina Ceramic Block Square Ceramic Tile

Square Ceramic Tile Alumina Ceramics Lined Hopper

Alumina Ceramics Lined Hopper Ceramic Lined Pipe

Ceramic Lined Pipe Pulley Lagging Ceramics

Pulley Lagging Ceramics Technical Ceramics

Technical Ceramics Square Ceramic Rubber Component

Square Ceramic Rubber Component Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Rubber backed alumina ceramic tiles

Rubber backed alumina ceramic tiles Engineered Ceramic Lined Pipe

Engineered Ceramic Lined Pipe SSIC Ceramic Seal Ring

SSIC Ceramic Seal Ring SSIC Ceramic Grinding Barrel Cylinder

SSIC Ceramic Grinding Barrel Cylinder Yttria-stabilized zirconia grinding beads

Yttria-stabilized zirconia grinding beads Mining Ceramic Grinding Balls

Mining Ceramic Grinding Balls Cement Mill Grinding Ball

Cement Mill Grinding Ball Ceramic Rubber Hose

Ceramic Rubber Hose Chemlok Glue For Vulcanization (252X)

Chemlok Glue For Vulcanization (252X) Dove-Tailor Ceramic Liner

Dove-Tailor Ceramic Liner 95% Grinding Cylinder

95% Grinding Cylinder Ceramic Cone

Ceramic Cone Customized Technical Ceramics

Customized Technical Ceramics Alumina Tube

Alumina Tube Alumina Ceramics bricks

Alumina Ceramics bricks Abrasion Advanced Ceramics

Abrasion Advanced Ceramics Ceramic Cyclone Liner

Ceramic Cyclone Liner Cutting Ceramic Tile

Cutting Ceramic Tile Curved Pipe Liner

Curved Pipe Liner Ceramic Chute Liner

Ceramic Chute Liner Stock Bin

Stock Bin Coking Plant

Coking Plant Mill Bricks Liner

Mill Bricks Liner SIC Cyclone

SIC Cyclone Silicon Carbide Bulletproof Tiles

Silicon Carbide Bulletproof Tiles Ceramic Lining Glue 8280

Ceramic Lining Glue 8280