Zirconia Ceramic Beads

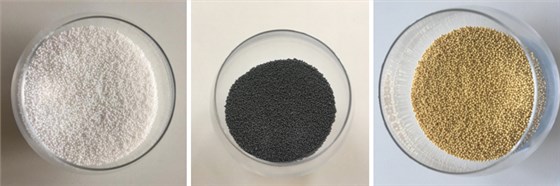

![]() Chemshun zirconia beads including Zirconium silicate beads, Zirconia toughened alumina beads, Ceria-stabilized zirconia beads, Yttria-stabilized zirconia beads.

Chemshun zirconia beads including Zirconium silicate beads, Zirconia toughened alumina beads, Ceria-stabilized zirconia beads, Yttria-stabilized zirconia beads.

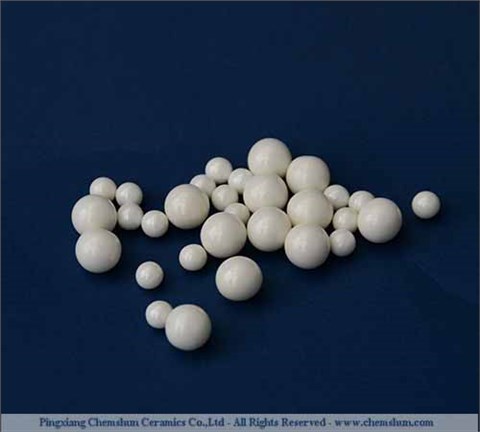

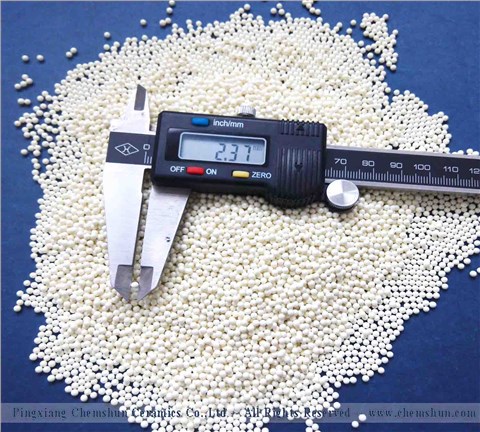

Chemshun zirconia beads, a kind of ceramic grinding media, havefeatures of good quality, no fracture, stable performance, reliable quality and long service life. They're low comprehensive operating cost which can effectively ensure that the abrasive material is not polluted, and maintain the high purity of the abrasive material. The high density of thezirconia ceramic beads can improve the grinding efficiency. And due to the low wear rate of zirconia mill balls, the stability of the grinding process condition can be effectively ensured. The stability and consistency of the quality of the raw material facilitates process control and management.

The Benefits of Zirconia Beads:

- High crushing strength and fracture durability superior wear resistance which has no any break under high speed impace. They can improve the efficience of grinding and no contamination.

- Smooth surface, good sphericity and low self-loss.

- High density and excellent grinding efficiency for grinding materials down to Nano size.

- Significant cost and waste reduction.

Techinal Date of Zironia Ceramic Beads:

Properties | Unit | SZS | ZTA | Ce-TZP | Y-TZP |

Composition | Wt% | 50~60% ZrO2 25~35% Al2O3 | 80~90% ZrO2 8~13% Al2O3 | 78~80% ZrO2 20~22% CeO2 | 94.6% ZrO2 5.2% Y2O3 |

Specific Density | G/cm3 | 4.0~4.2 | 5.1-5.3 | 5.95~6.05 | 5.95-6.0 |

Moh’s Hardness | Grade | ≥9 | ≥9 | ≥9 | >9.0 |

Vickers hardness | Hv | 1000~1050 | 1350~1450 | 1300~1400 | 1200~1250 |

Elastic Modulus | Gpa | - | - | 200 | 205 |

Thermal Conductivity | W/m,k | - | - | 3 | 3 |

Fracture Toughness | Mpam1/2 | - | - | ≥8.5 | 7-10 |

Grain Sizes | µm | - | - | ≦0.5 | 0.1--55 |

Thermal Expansion Coefficient (20~400 ℃) | 10*10-6/℃ (20-400) | - | - | 9 | 11 |

Zirconia Ceramic Balls Application :

It is suitable for grinding and dispersion of ultra-finematerial such aselectronic ceramics, magnetic materials, highpurity ceramics material such as alumina oxide, silicon oxide, zirconium silicate and titanium dioxide: foodstuffs, cosmetic and pigment, inks, paint and coating materials.

Product Technical Data(2- Ceramic Grinding Media)

Ceramic Tile Liner

Ceramic Tile Liner Weldable alumina tile

Weldable alumina tile Curved Pipe Tile Liner

Curved Pipe Tile Liner Alumina Ceramic Pipe Liner

Alumina Ceramic Pipe Liner AL92 Ceramic Rubber Chute Liner

AL92 Ceramic Rubber Chute Liner Trapezoidal Pipe Tile

Trapezoidal Pipe Tile 90 degree pipe elbow

90 degree pipe elbow Wear Resistant Ceramic Liner

Wear Resistant Ceramic Liner (SISIC) Silicon Carbide Ceramic Plate

(SISIC) Silicon Carbide Ceramic Plate Cyclone Pipe Liner

Cyclone Pipe Liner 92% Aluminium Oxide Pipe Ring

92% Aluminium Oxide Pipe Ring 92% High Alumina Grinding Ball

92% High Alumina Grinding Ball Ceramic Liner With Salient Point

Ceramic Liner With Salient Point Alumina Cylinder

Alumina Cylinder Ceramic Rubber Composite Liner

Ceramic Rubber Composite Liner Ceramic Epoxy Resin Glue

Ceramic Epoxy Resin Glue Hex Rubber Ceramic Wear Plate

Hex Rubber Ceramic Wear Plate 95% Alumina Engineering Ceramics

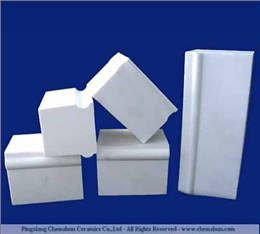

95% Alumina Engineering Ceramics Alumina Ceramic Block

Alumina Ceramic Block Square Ceramic Tile

Square Ceramic Tile Alumina Ceramics Lined Hopper

Alumina Ceramics Lined Hopper Ceramic Lined Pipe

Ceramic Lined Pipe Pulley Lagging Ceramics

Pulley Lagging Ceramics Technical Ceramics

Technical Ceramics Square Ceramic Rubber Component

Square Ceramic Rubber Component Rubber Ceramic Wear Liner

Rubber Ceramic Wear Liner Rubber backed alumina ceramic tiles

Rubber backed alumina ceramic tiles Engineered Ceramic Lined Pipe

Engineered Ceramic Lined Pipe SSIC Ceramic Seal Ring

SSIC Ceramic Seal Ring SSIC Ceramic Grinding Barrel Cylinder

SSIC Ceramic Grinding Barrel Cylinder Yttria-stabilized zirconia grinding beads

Yttria-stabilized zirconia grinding beads Mining Ceramic Grinding Balls

Mining Ceramic Grinding Balls Cement Mill Grinding Ball

Cement Mill Grinding Ball Ceramic Rubber Hose

Ceramic Rubber Hose Chemlok Glue For Vulcanization (252X)

Chemlok Glue For Vulcanization (252X) Dove-Tailor Ceramic Liner

Dove-Tailor Ceramic Liner 95% Grinding Cylinder

95% Grinding Cylinder Ceramic Cone

Ceramic Cone Customized Technical Ceramics

Customized Technical Ceramics Alumina Tube

Alumina Tube Alumina Ceramics bricks

Alumina Ceramics bricks Abrasion Advanced Ceramics

Abrasion Advanced Ceramics Hexagonal Alumina Tile

Hexagonal Alumina Tile Ceramic Cyclone Liner

Ceramic Cyclone Liner Cutting Ceramic Tile

Cutting Ceramic Tile Curved Pipe Liner

Curved Pipe Liner Ceramic Chute Liner

Ceramic Chute Liner Stock Bin

Stock Bin Coking Plant

Coking Plant Mill Bricks Liner

Mill Bricks Liner SIC Cyclone

SIC Cyclone Silicon Carbide Bulletproof Tiles

Silicon Carbide Bulletproof Tiles Ceramic Lining Glue 8280

Ceramic Lining Glue 8280