Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

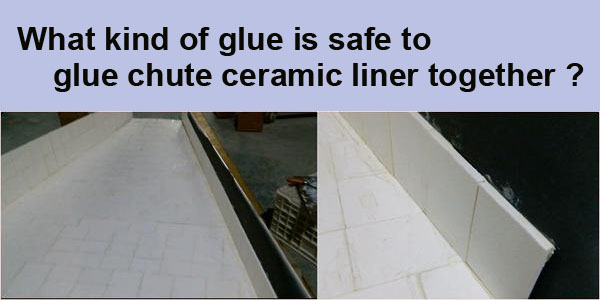

what kind of glue is safe to glue chute ceramic liner together ?

what kind of glue is safe to glue chute ceramic liner together ?

Most of material handling system use chute for conveying, like mining,port,power generation,steel plant etc. Chute ceramic liner is most popular wear protective liners as abrasion resistant materials. Chemshun Ceramics can produce and supply kind of chute liners like alumina tile, rubber ceramic plate , but some users will ask, what kind of material can be used to install ceramic tile liner ?

As China ceramic supplier and exporter, Chemshun Ceramics introduce several adhesive glue for your application :

- Ceramic Epoxy Resin Glue: It has advantage of solidifying quick at room temperature, strong bonding strength, good toughness, excellent impact strength. It appear the paste status after the type A and type B mixing with strong bonding and without flowing. It is suitable for the vertical face fixing. Working temperature range: - 60~150℃. widely used as stick ceramic surface and metal surface in all kind of conditions.

- Chemlok Glue for vulcanization (252X): Widely make all kinds of rubber and metal substrate meterials glued togeter by hot vulcanization .Rubber includes natural rubber, polyisoprene rubber, styrene-butadiene rubber, butadiene rubber, neoprene, nitrile rubber,butyl rubber and EPDM rubber.; substrate: carbon steel. Steel, stainless steel. aluminum. copper. Copper alloys, magnesium and zinc and other metals as well as plastics and textile fibers.

- Cement : Cement is another materials used to fix ceramics when working environment is much high.

The fixing material above depend on different chute ceramic liner installation environment. Chemshun Ceramics supply ceramic glue in website :www.chemshun.com , welcome to visit.