Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

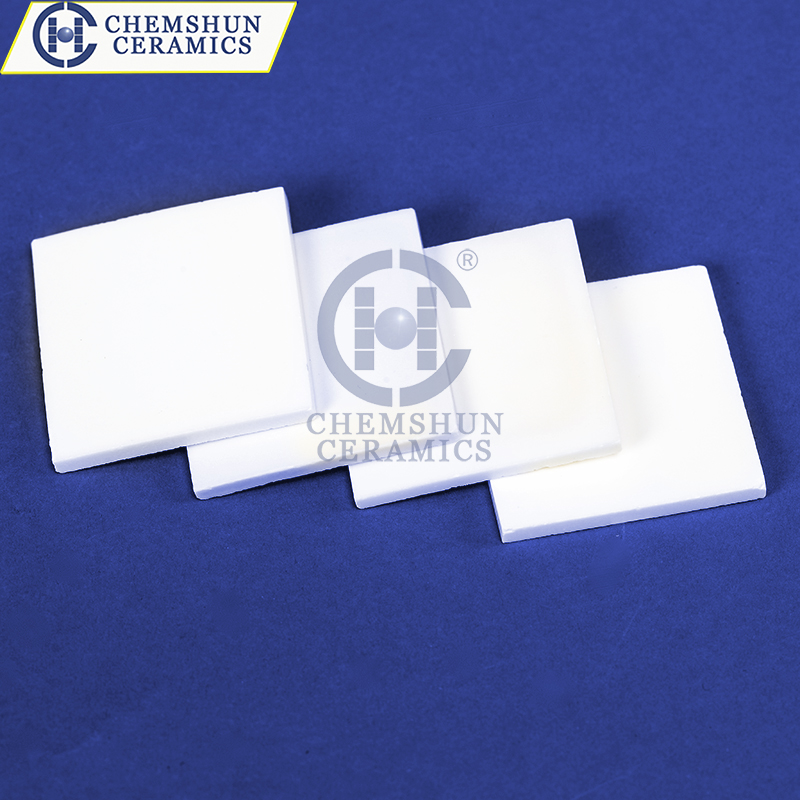

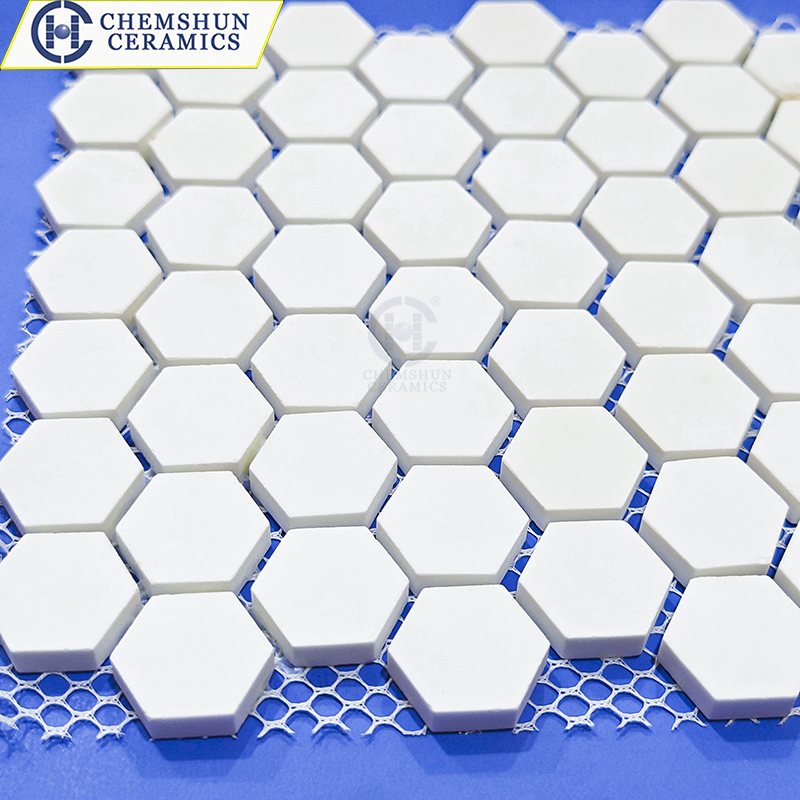

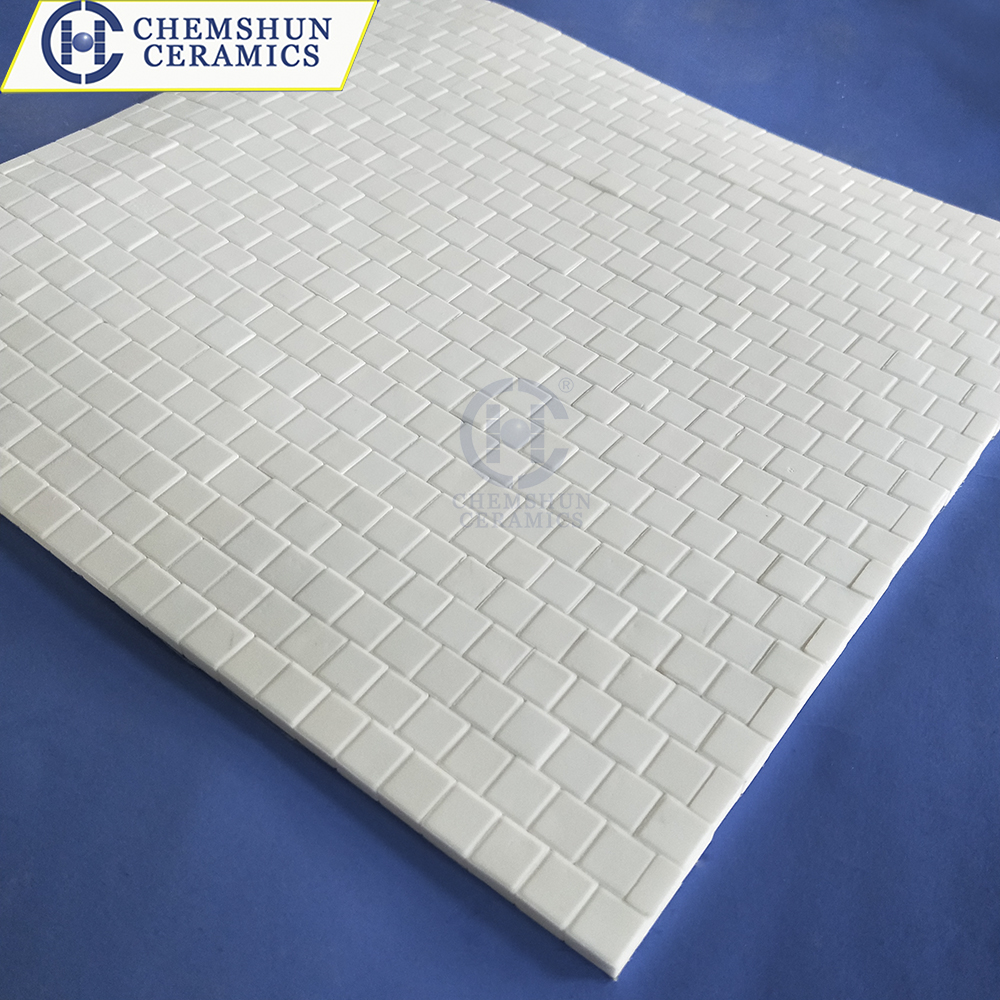

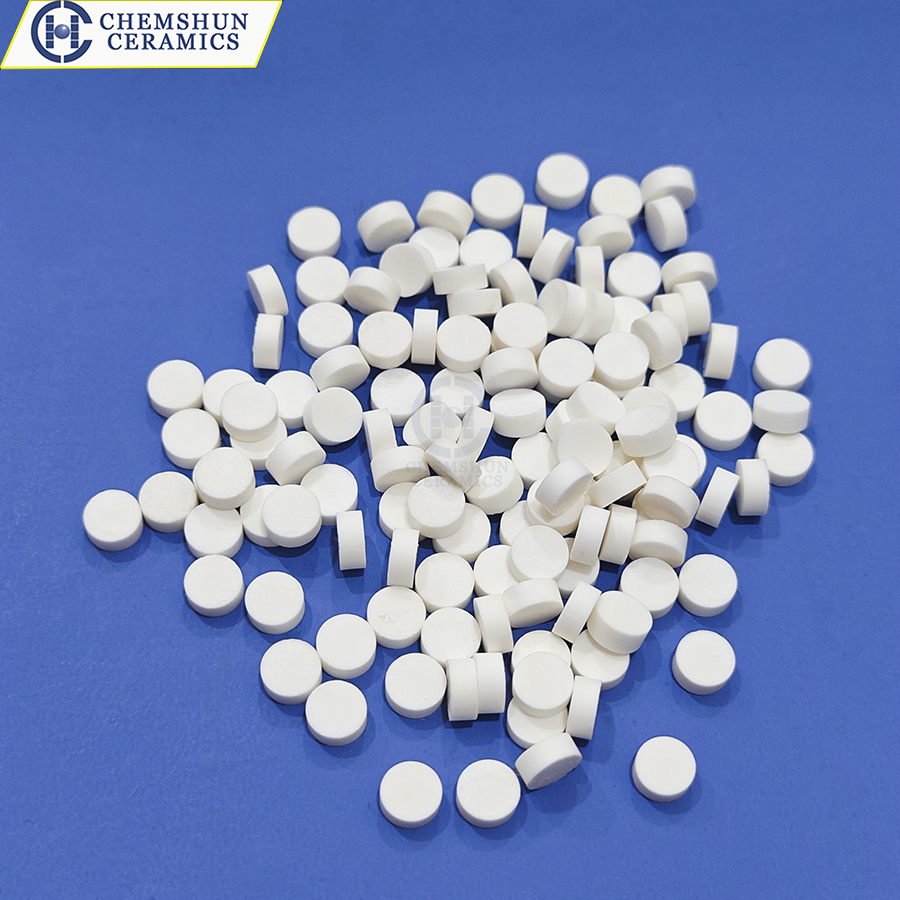

What is the difference between 92% and 95% aluminum ceramic pieces

There are differences in performance between 92% aluminum and 95% aluminum wear-resistant ceramic pieces, as follows:

Hardness. The wear-resistant ceramic pieces with 95% aluminum content has higher hardness than that with 92% aluminum content, which improves its wear resistance to a certain extent. Therefore, the hardness may affect the durability of wear-resistant ceramic pieces.

Brittleness and curvature. The toughness of the wear-resistant ceramic pieces with 92% aluminum content is relatively strong, while the wear-resistant ceramic pieces with 95% aluminum content may be more brittle and may crack during bending or use. This may affect its performance in practical applications.

The price. 95% aluminum wear-resistant ceramic pieces because of its higher aluminum content and hardness, the production cost is usually higher, so compared with 92% aluminum wear-resistant ceramic pieces, 95% aluminum wear-resistant ceramic pieces price will be slightly higher.

In general, these two kinds of wear-resistant ceramics have their unique characteristics and advantages, the specific choice of which type, need to be based on application conditions, frequency of use, cost control and other factors for comprehensive consideration. At the same time, in order to ensure the effect of use, it is recommended to choose professionals for selection and installation when replacing ceramic pieces.