Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Wear-resistant Ceramics Play an Important Role in Cement Industry

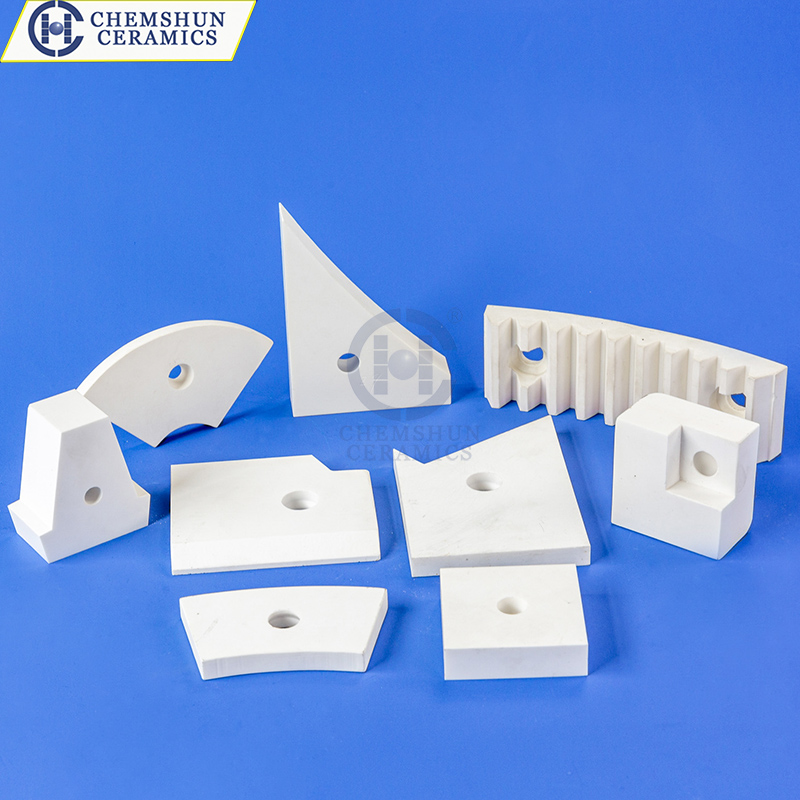

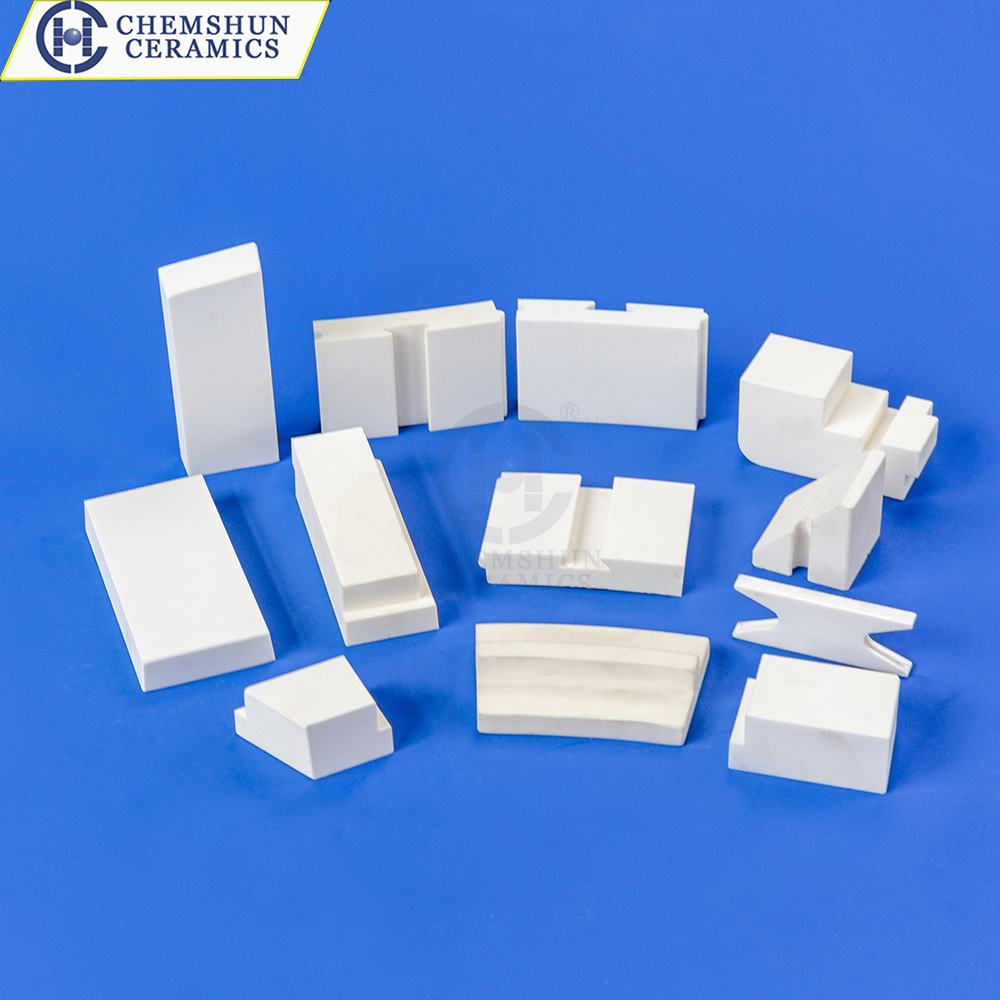

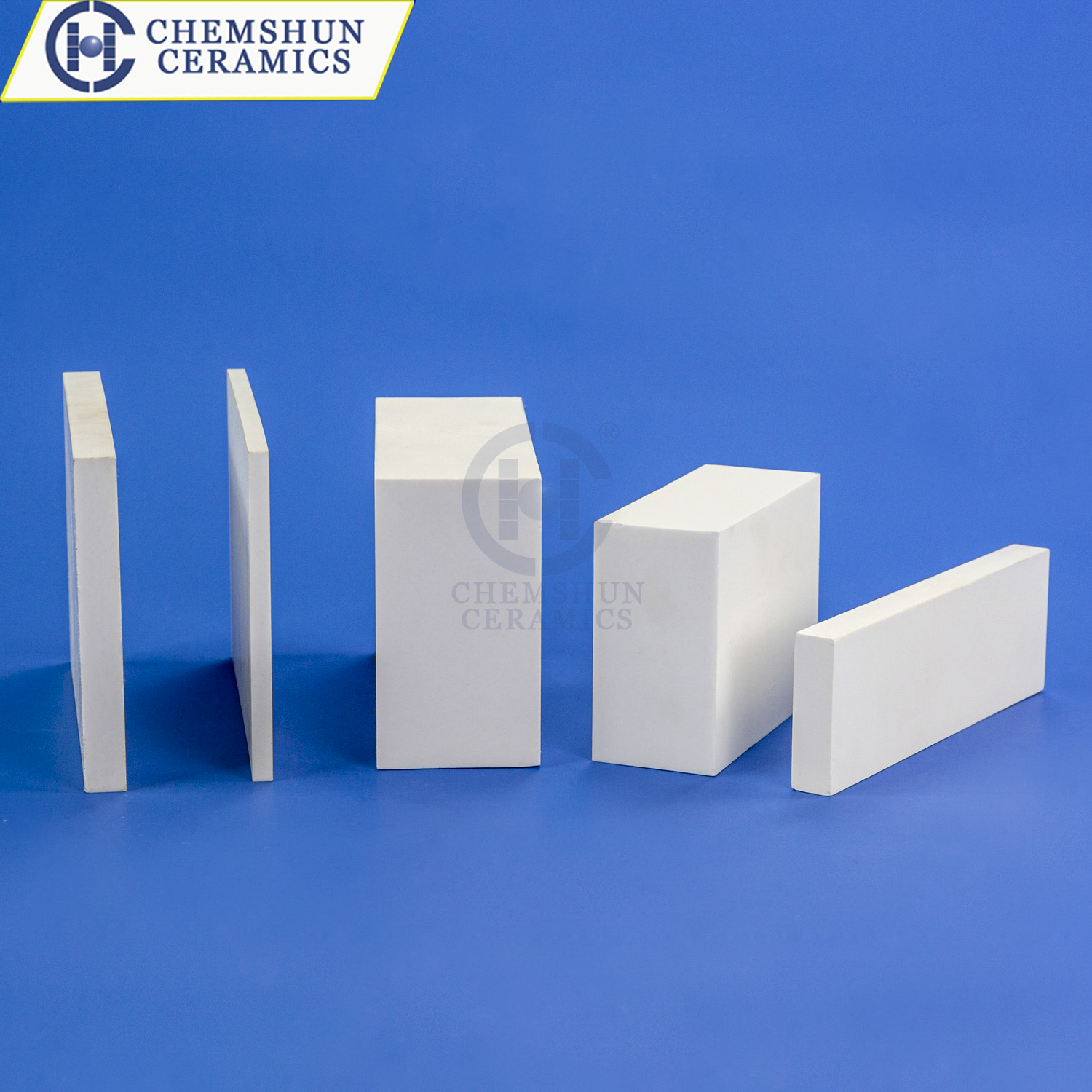

Wear-resistant ceramics do play an important role in the cement industry. Wear-resistant ceramic lining is a kind of wear-resistant material with high wear resistance and corrosion resistance, which can withstand extreme environments such as high pressure, high temperature and low temperature. In the cement industry, wear-resistant ceramic lining can be installed on a variety of equipment that needs to resist wear, such as conveying pipes, lifting equipment, crushing equipment, mixing equipment, etc. After these devices are installed with wear-resistant ceramics, the wear rate can be significantly reduced, the service life of the equipment can be extended, the production efficiency can be improved, and the cost can be reduced. In addition, wear-resistant ceramic liner has the advantages of easy installation, convenient maintenance and high cost performance. It has been widely used in cement industry.

1. Elevator lining: wear-resistant ceramic lining plate can be used as the lining of the elevator, such as scraper elevator, bucket elevator, ball mill, etc. They can effectively protect the parts inside the machine from wear, extend the service life of the equipment, and improve production efficiency.

2. Abrasive body: wear-resistant ceramics can also be made into abrasive bodies for material grinding and dispersion in the cement industry. The grinding ball and other grinding bodies made of this material can effectively improve the grinding effect of the material, reduce energy consumption and improve production efficiency.

3. Pipes and valves: wear-resistant ceramics can also be used in the manufacture of pipes and valves to enhance their wear resistance and corrosion resistance. This can extend the service life of pipes and valves, reduce the frequency of maintenance and replacement, and reduce production costs.

4. Crusher lining: wear-resistant ceramic lining can also be used for the lining of the crusher to enhance its wear resistance, prevent the wear of the material on the internal parts of the machine, and extend the service life of the equipment.

The application of wear-resistant ceramics in cement industry can effectively improve the production efficiency of equipment, reduce production costs, and reduce the frequency of maintenance and replacement. Wear-resistant ceramic materials have been widely used and recognized in cement industry.