Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

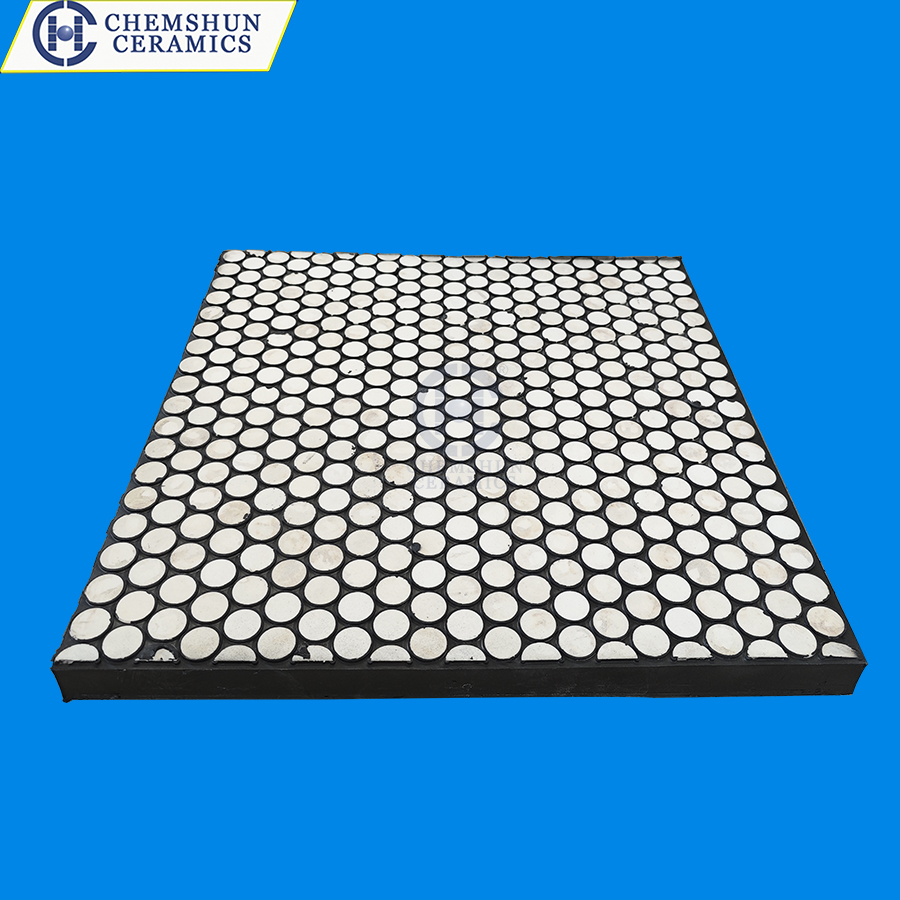

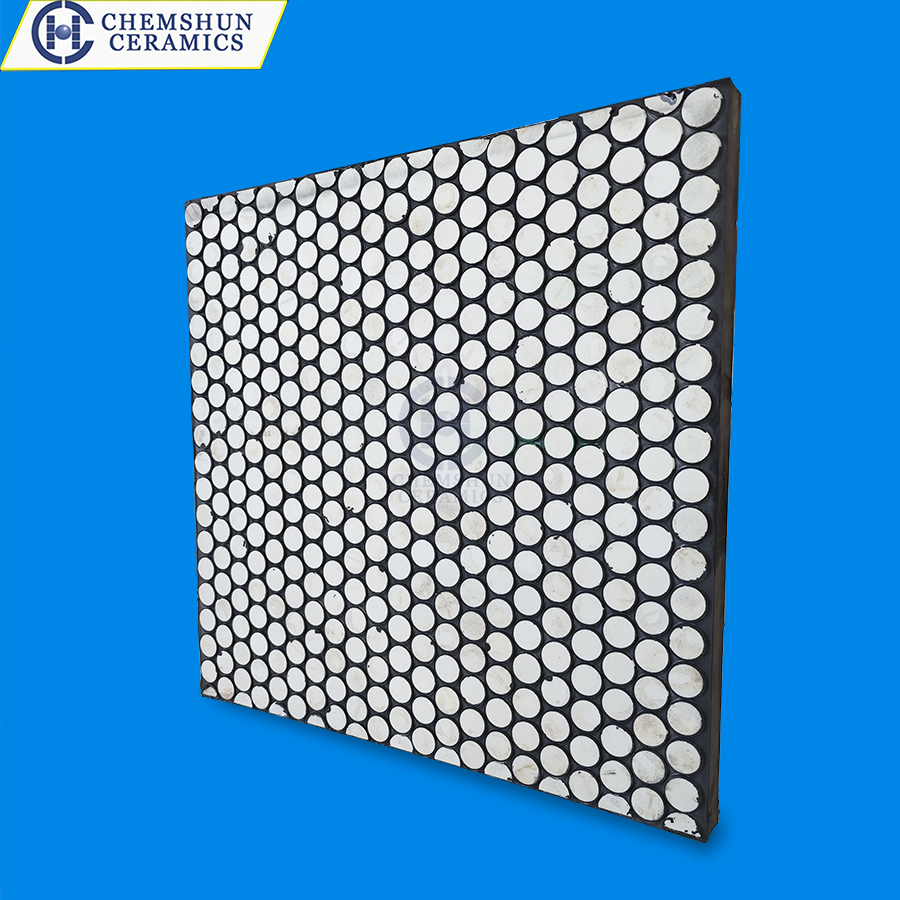

Wear Resistant Ceramic-rubber Panel Lined with Ceramic Cylinder

The rubber ceramic liner is with high wear resistant ceramics vulcanized in resilient rubber. The ceramics provide excellent resistance to wear, while the elasticty of rubber effectively dampens impact forces. This combination well solves the problem of the wear and impact areas. The ceramic-rubber composite plate can be directly installed in the wear area of the equipment as an anti-wear layer; It can also be installed and fixed by stud or welding after composite with steel plate.

Wear-resistant ceramics that can be vulcanized in rubber have a variety of shapes, cylindrical ceramics, square ceramics, hexagonal ceramics and so on.

Compared with square, hexagonal and other ceramic rubber vulcanized lining plates, the rubber coverage rate of cylindrical ceramic lining plates is higher, which can play a better buffer effect and have stronger impact resistance.

The ceramic cylinder has less sharp edges and corners than other shapes of lining plates, and it is not easy to break the edge when the material is impacted.

The cylindrical ceramic rubber three-in-one liner adopts modular design, production and assembly, which can replace heavy wear areas and make installation and replacement easy and fast.

The ceramic cylinder rubber liner is widely used in cement plants, power plants, iron and steel plants, mines, docks and many other industries in the material wear serious, strong impact conveying equipment and systems. However, because the cylindrical ceramic liner has more rubber components, it is necessary to avoid high temperature conditions as much as possible.