Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

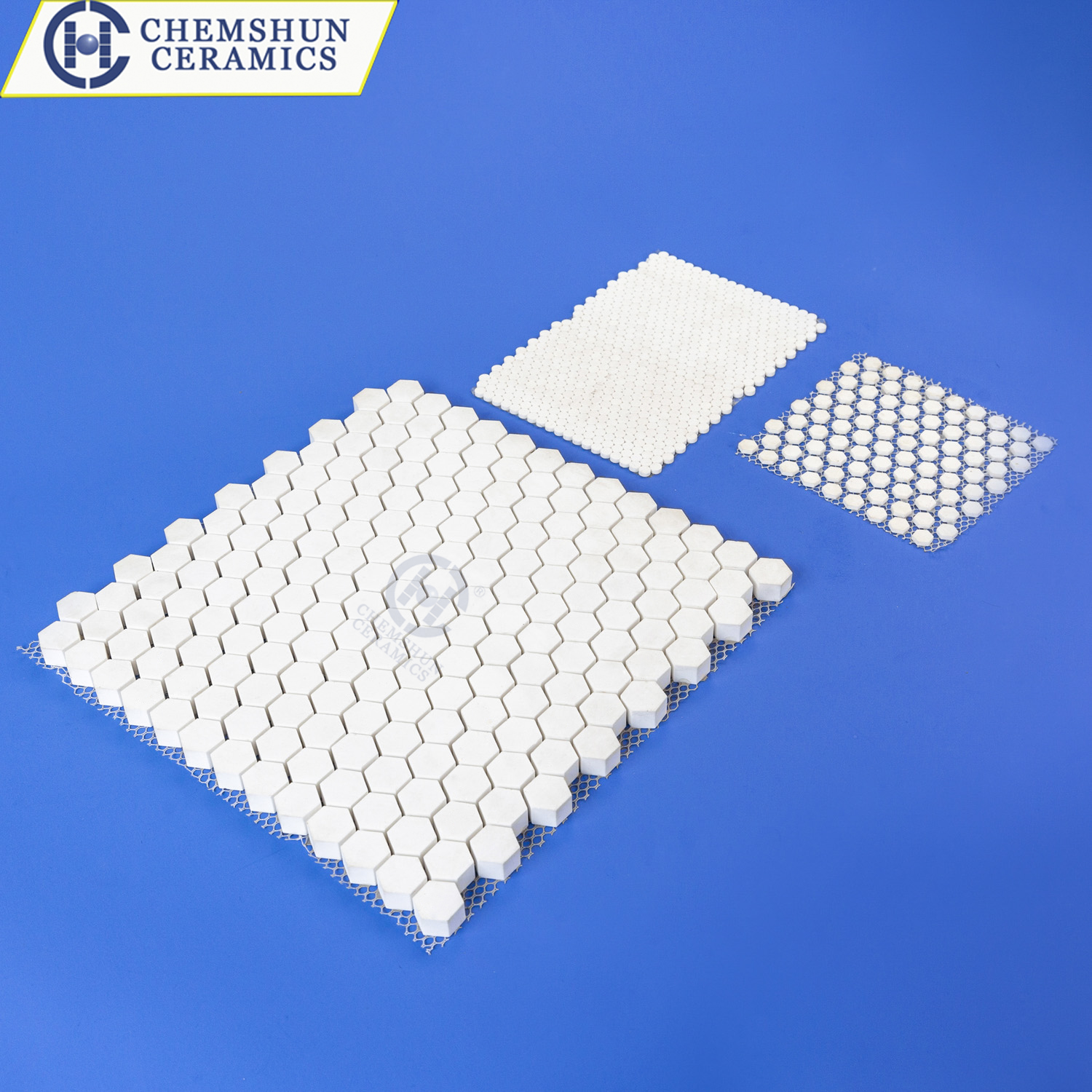

High Wear Resistance Alumina Wear-resistant Ceramic Sheet

Wear-resistant ceramic sheet is a kind of high wear-resistant material, the main material is aluminum oxide. Wear-resistant ceramic sheet has high hardness, wear resistance, corrosion resistance, high temperature resistance and other characteristics, can be used in a variety of high wear or corrosion environment.

However, wear-resistant ceramic sheets also have some disadvantages, such as fragile, can not contact with hard objects such as metal bars, otherwise it will damage the ceramic sheet. These matters need to be paid attention to when installing and using wear-resistant ceramics.

Wear-resistant ceramic sheet installation method is simple. Use ceramic glue, epoxy resin glue. Before installation, wipe the dust and oil stains on the surface of the device, stir the glue A and B according to the proportion, and stir until the color is the same. If abnormal phenomena such as obvious clumps, particles, and dryness occur, it indicates that the glue may be damp and caked, and you need to replace the glue. Apply the mixed glue on the surface of the ceramic, and then paste it on the equipment, check the smooth condition of the ceramic in time after pasting, and adjust it. After the glue is completely cured (about 24 hours), gently tap the tile with a small hammer. If there is no empty drum sound, the installation is complete.

Wear-resistant ceramic sheet have good wear resistance, corrosion resistance, high temperature resistance and impact resistance, and can be widely used in a variety of high wear or corrosion environments to improve the performance and life of mechanical equipment. Such as machinery and equipment, chemical industry, power plant, steel, mining and other industries.