Top articles

- Chemshun Ceramics Chinese New Year Holiday Notice

- Chemshun Ceramics wishes you a Merry Christmas

- Chemshun Chinese New Year Holidays Notice

- Chemshun Hold the Fifth Fun Games on October 21, 2023

- Participate in the PERUMIN 36rd Mining Convention Extemin 2023

- A Kiln Ignition Ceremony Was Held at The Chemshun New Factory

- Chemshun Organized Employees to Plant Trees in The New Factory Perimeter

- Chemshun Conference of 2022 Summary Commendation & 2023 Work Started

- Autumn crisp, Chemshun Ceramics Held the Fourth Fun Sports Games

- Chemshun Ceramics Held a Tug-of-war Competition

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

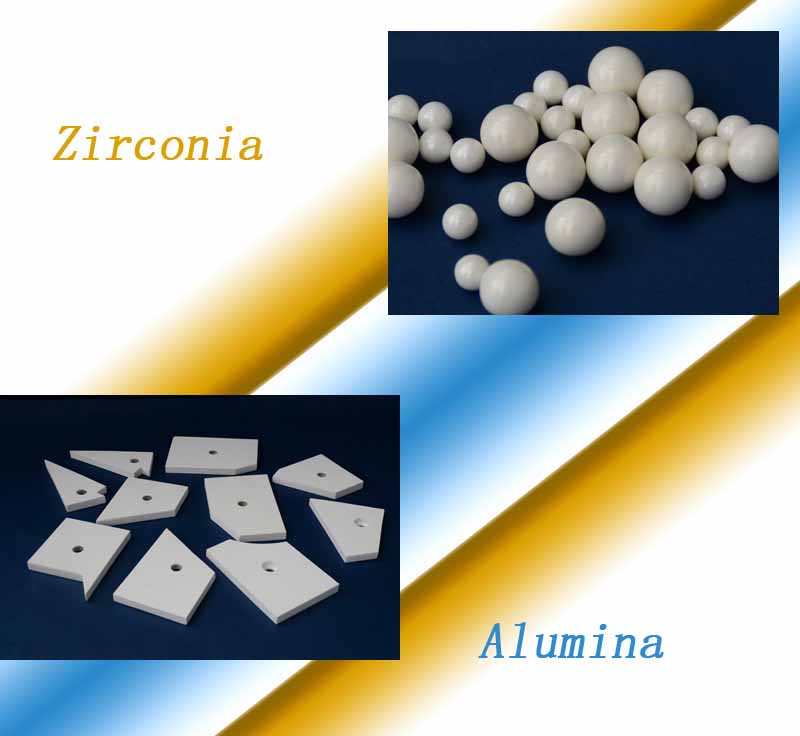

Comparision Alumina and Zirconia Engineering Ceramics

A Comparison of Alumina and Zirconia Engineering Ceramics

N0.1: Alumina is Harder than Zirconia So It Must be More Wear Resistant?

Although it’s commonly accepted that hardness equates with wear resistance, it’s not always the case. In sliding wear environments, hard counterfaces that do not interact with each other are an advantage. The engineering grades of Alumina are typically 25-50% harder than zirconia grade so in sliding wear environments or pure abrasive wear, where third body abrasive wear particles are present, alumina often outperforms Zirconia.

No.2: Which is The Most Corrosion Resistant Alumina or Zirconia?

Again, this is a very difficult question that can only be answered on a case-by-case basis by reference to an expert manufacturer. The combination of corrosive agent, chemical purity and temperature lead to a wide range of performance characteristics that are further varied by the individual composition and grade of Alumina or Zirconia. Do not think that because a material has excellent resistance to concentrated sulphuric acid it will perform well in steam at 200°C

A Final Word on Material Selection

Selecting the optimum material for a specific application always involves a decision tree constructed from a series of compromises. It is far too simplistic to say material A is always better than material B, because one must take into account the application, the environment and the available budget. The use of bare material specifications can also be dangerous as it can be all too easy to miss the key variable or combination of variables that are key to selecting the optimum material solution.

As is often the case, it’s always good to talk to an expert and if you are considering an engineering application that you feel may be suited to zirconia or alumina, why not consult someone like Chemshun – www.chemshun.com they have many decades of experience on manufacturing and designing engineering ceramics according to industrial abrasion problems.

Information about "Industry News "

- Weldable tile and Its Installation

- Factors affected the proerty of wear resistant ceramics

- Abrasion resistant ceramic wear tile liner used in the milling system shows good prospects for development

- The reason why abrasion resistant ceramic lined pipe is so popular ?

- World's largest mining project takes $1 billion hit

- Anglo American may fully exit Brazil — report

- Is ceramic liner applied in temperature 280 degree ?

- Chemshun Wear-resistant alumina ceramic liner

- China shutting another 4,300 coal mines

- BHP takes largest-ever write-down on US shale operation