Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

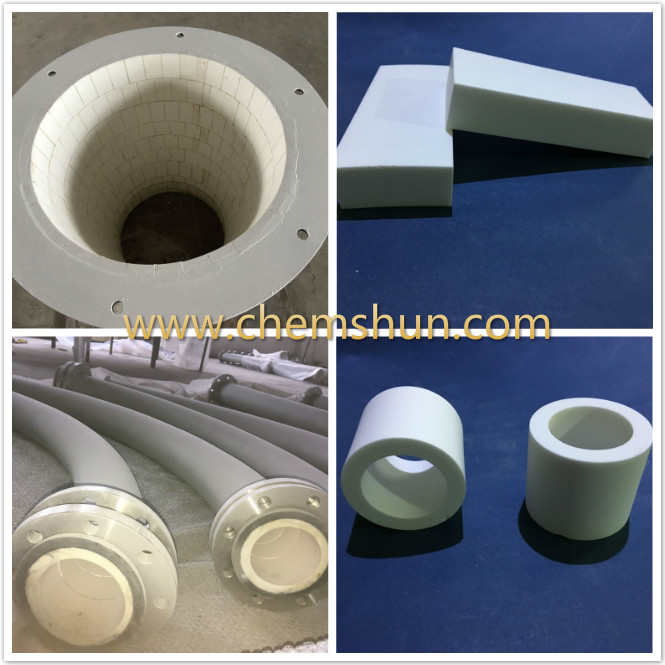

Wear Resistant Ceramic For The Integrated Equipment

In wear resistant ceramic field, sometimes the clients purchase the integrated equipment

( equipment with ceramic lining) for their system. Why ? It's a better

way to avoid the installation ceramics, choose the best suitable glue,

and painting of the steel and welding works. From the cost side and

quality side, professional work is left to professionals. It is

convenient that the customers directly use the integrated equipment to

match their current operation machine meantime it can save lots of time.

Here we Pingxiang chemshun ceramics want to popularize two simple kinds of the integrated equipment -steel pipes with ceramic lining, they are straight steel pipe and elbow steel pipe.

When

we face the steel pipe, the technical engineer need to know the

Length, OD, ID, wall thickness of the steel pipe, and the actual application

parameters in the design drawing, our technical team will choose a good

type of wear resistant ceramic pasted on the surface of the steel pipe,

such as trapezoid ceramic tile, alumina ceramic tubes,rectangular

ceramic tile etc, as well as the suitable ceramic thickness for the

application between 15-30mm, also the client appointed the exact

thickness which bear the material friction.

Generally if the OD, ID, Length, wall thickness of the straight steel pipe are clear, we recommend the ceramic tubes or trapezoid ceramic tile of 15-25mm thickness as lining, also leave2-3mm thickness space for glue connecting the ceramic and steel pipe.

If it is elbow steel pipe, the length,OD,ID, wall thickness,the bending radius ,and angle of bend ,arc length are necessary before our give the suggestion for the the wear resistant ceramic solution. Commonly the ceramic tubes are mostly used in the elbow steel pipe. the thickness depends on the friction of the material through the pipe. Then a complete specification elbow steel pipe can be formed between the interaction among the demand side and the supply side.

Pingxiang Chemshun Ceramics is a professional manufacturer of wear resistant ceramic & ceramic grinding media,we also can provide a engineering solution for kinds of the integrated equipment.

If you have any interest, you can contact us by mail: office@chemshun.com or call us by the telephone : +86-799-6790781.