Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Factors Affecting the Wear Resistance of Abrasive Alumina Ceramic Materials

Wear-resistant ceramic materials are widely used in various fields of industrial production, and with the rapid development of science and technology and modern industry, the economic losses caused by the increase in energy and material consumption caused by material wear are quite alarming. Starting from wear-resistant ceramic materials, let’s analyze the factors that affect the wear resistance of wear-resistant ceramic materials.

①Grain size that affect the performance of wear-resistant ceramics

Research on the wear resistance of alumina and zirconia ceramics has found that when the crystal grains are small, plastic deformation and partial transgranular fracture are mainly caused, resulting in slight abrasion; What happens inside is mainly intergranular fracture, and large crystal grains are pulled out from the inside of the material as a whole, causing serious wear. Therefore, as the grain size decreases, the wear resistance of ceramics is gradually improved.

②Porosity that affects the performance of wear-resistant ceramics

In wear-resistant ceramics, pores have a very important influence on the performance of ceramics. The pores are equivalent to the existence of a kind of defect, which will cause stress concentration, accelerate the propagation of cracks, reduce the bonding strength between grains, and seriously affect ceramic products. The mechanical properties. Under the action of friction, the pores may be connected to each other to form a source of cracks, accelerating the wear of the material. The presence of pores will greatly reduce the wear resistance of ceramic products. Studies have also shown that under different loads, when the porosity increases, it is easy to cause intergranular fracture, trigger abrasive wear, and accelerate the process of wear.

③IGrain boundary phase and intergranular impurities that affect the performance of wear-resistant ceramics

Wear-resistant ceramics are composed of grains, grain boundary phases and pores. During the sintering process, some additives and some impurity components added to the ceramic are mainly present on the grain boundaries in the form of the second phase or glass phase. Their existence will have a certain impact on the bonding strength between the grains. In the process of ceramic friction and wear, cracks are easily generated at the grain boundaries. The lower bonding strength of the grain boundaries will cause the intergranularity during the wear process. Fracture, causing pulling out of the whole piece of crystal grains, causing serious wear.

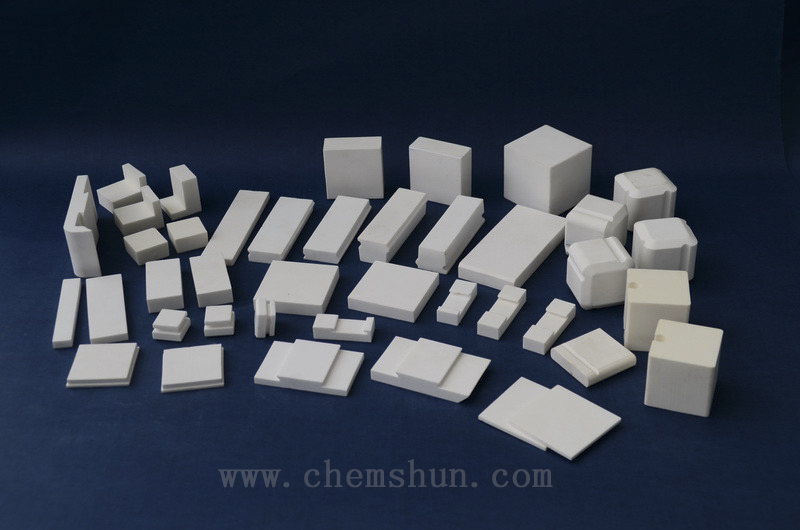

Finally, due to the excellent performance of ceramic materials in the industrial field, it is very important to study and grasp the factors that affect the wear resistance of wear-resistant ceramics so that they can better serve modern industries.Pingxiang Chemshun Ceramics Co.,Ltd has studied ceramic materials for many years and can produce high-quality wear-resistant ceramics, such as: wear-resistant ceramic liners, alumina ceramic linings, alumina ceramic tubes, rubber ceramic linings, etc. Wear-resistant ceramic products have the characteristics of high strength, high hardness, wear resistance, corrosion resistance, etc., and can be widely used in non-metallic minerals, cement, steel, chemical, power plants and other industries.