Top articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

Wear resistant ceramics applied on the blower impeller can extend the life of 15 years

Wear resistant ceramics applied on the blower impeller can extend the life of 15 years

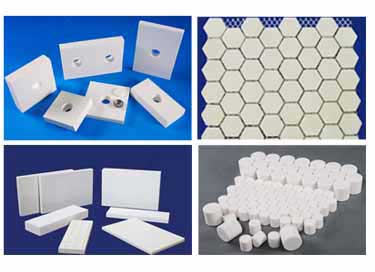

In the dry process production lines, powder transport provided mainly by the power offered from fan, high-speed rotation of the fan cause dust particles airflow and fan blade to mutally effect ,resulting in impeller wear damage seriously. Now the use of wear resistant ceramics can extend the life of the fan impeller.

For a long time , cement companies generally use hardfacing, thermal spraying as traditional abrasion solution methods, the effect is not ideal, but will also cause stress concentration. using wear resistant ceramics as impeller protection liner is the best approach, but people need to overcome high speed ceramic shedding problems, while make sure that increasing weight of the ceramic does not affect the start-up and normal operation of the impeller.

Pingxiang chemshun ceramics co.ltd is a professional wear resistant ceramics supplier ,we can design , produce , install all kinds of industrial ceramic linings, for solve impeller abrasion problem ,we explore a way to repair fan impeller by inserted dovetail wear-resistant ceramic linings. And we can provide a series of solutions for static and dynamic balance. ceramics and impeller are linked closely together by the process producing ceramic liner , and alumina ceramic density is low, the weight is much lower than the commonly used steel wear liner , impeller total weight become less weight , which increases the service life of the main bearing fan, impeller lined abrasion resistant cerics can extend the life of more than 15 times, not only greatly reduce the frequency of replacement of the impeller significantly improve the operation rate of the equipment, reducing operating and maintenance personnel work intensity.

This process has four major advantages:

1 improve the life of more than 15 times;

2 unique process to ensure that the ceramic does not fall off;

3 does not change the parameters of the impeller;

4 Total weight increased less than 10%, does not affect the fan starts.

welcome to inquiry chemshun ceramics , website : www.chemshun.com www.chemshun-es.com office@chemshun.com