Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

GreatIy improves Production capacity of toughened alumina ceramics

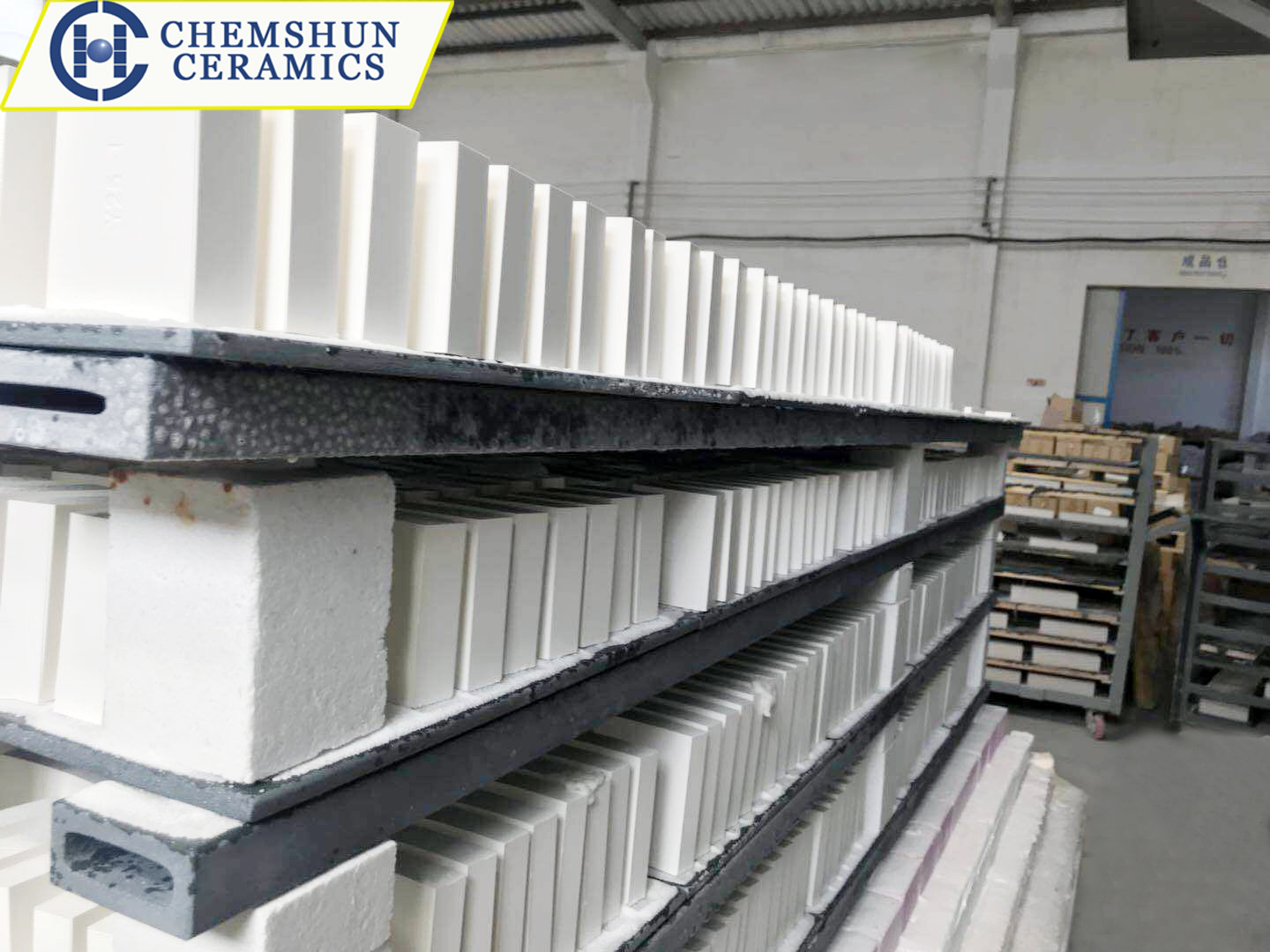

GreatIy Improves Production capacity of toughened alumina ceramics

Alumina wear resistant ceramic has excellent characteristics, such as high temperature resistance, high strength, creep resistance, wear resistance, good insulation, light weight,which is an ideal wear resistant material, which has been widely used in many industries. With the development of science and technology, its application area has been continuously expanded. As a new material, it has been used in more complicated fields. This has also put forward higher requirements for the performance of alumina ceramic materials. Because of the brittleness of alumina ceramic materials, its application range is limited. In order to overcome the brittleness of ceramic materials and improve safety and reliability, ceramicists have taken toughening as one of the important topics. A variety of ceramic materials have been proposed Toughening mechanism, among which ZrO2 toughening and fiber toughening are more mature and widely used toughening methods.

Pingxiang Chemshun Ceramics has carried out many years of research in the direction of zirconia toughened alumina ceramics. Since 2016, the ZTA project has been officially launched. The company has invested a lot of funds, introduced professional and technical personnel and advanced equipment, and targeted the formulation, process and other aspects Research and experiment. After long-term research and precipitation, our company has made breakthrough progress in zirconia toughened alumina ceramic materials. Chemshun Ceramics uses centrifugal granulation, isostatic pressing of embryos, and electric kiln firing. It now has a large-scale production capacity . In 2019, through process improvement and effective management, we not only improved product quality, but also reduced production costs and increased the competitive advantage of Chemshun ZTA products.

Chemshun Ceramics zirconia toughened alumina ceramics has reached domestic advanced level and is exported to many countries and regions, and has been recognized by foreign customers in practical applications