Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Single-side grinding and polishing machine processing principle

Single-side grinding and polishing machine processing principle

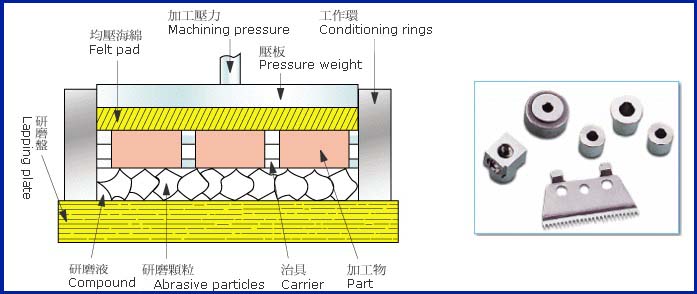

Lapping / polishing is the effect of free-abrasive between the grinding disc and the flat workpiece, applying appropriate pressure to the workpiece, and the cutting effect of the non-directional grain surface produced by the workpiece, when the abrasive particles become fine and grinding If the disc (polished leather) is matched, the surface of the workpiece can achieve the mirror effect. In terms of grinding action, the single-sided machine is 2ways.

The plane grinding and polishing machine can be applied to flat workpieces of different materials. At the same time, the flatness of the grinding disc is controlled during processing to improve the accuracy of the workpiece, reduce the surface roughness, and achieve the nano mirror effect. The R&D department provides process solutions according to the unique needs of customers. , So that it can meet the full range of customer needs。

The operation principle of the icon plane grinding and polishing machine.

(Various customized functions can be selected according to the manufacturing process)

1. Cooling circulation system of grinding disc

2. Slurry supply system

3. Thickness control jig

4.POWER HEAD

5.POWER ARM

6. Swing mechanism

7. Thickness setting

8. Vacuum suction cup

Processing example of plane grinding and polishing machine:

Stainless steel mirror mold, vacuum chuck, semiconductor chip (eg: silicon wafer GaAs, GaP, LiNbO3, LiTaO3, etc), crystal glass (Sapphire), ceramic parts, tungsten carbide parts, copper and aluminum parts, ultrasonic welding head, vibrating sub parts , Ferrite, mechanical shaft seal, printing steel plate, needle car parts, glass, quartz.