Top articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

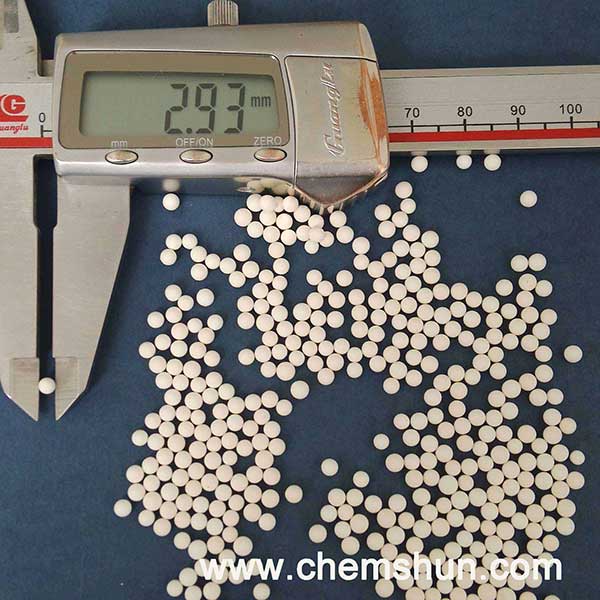

ceramic grinding media ball

ceramic grinding media ball -- Zirconium aluminium silicate

1: Comparision of grinding media:

ceramic grinding media ball are small ceramic balls that are used in high intensity stirred mills for fine and ultra fine grinding applications. The grinding media are available in a multitude of sizes and composition.

Steel and chrome steel grinding media were traditionally used in the mining and metallurgical industry, but the use of ceramic grinding media is growing. Particularly as an inert grinding media for applications where downstream processes are sensitive to surface chemistry.

In the fine and ultra fine milling applications, silica sand and industrial slags are often used as alternatives to ceramic media, but their angular shape and high wear rates, together with increased “slimes” generation, makes these alternatives inferior to ceramic grinding media.

Ceramic grinding media can be manufactured from a range of materials and can be formed by a number of different manufacturing processes. Both of these factors – composition and the manufacturing method – influence the quality of the grinding media. Material composition also determines the density of the ceramic grinding media and hence its impact force.

2: Technical data

| Alumina content : | AL2O3 70% |

| Density : | 2.90g/cm3 |

| Shape : | Spherical polished balls |

| Color : | White |

| Popular size: | 1.5~15mm |

3: Main application :

----- Wet grinding of mineral ores (gold, platinum - PGM, silver, magnetite). Large scale.milling of calcium carbonate and titanium dioxide. Used in both vertical and horizontal stirred mills