Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

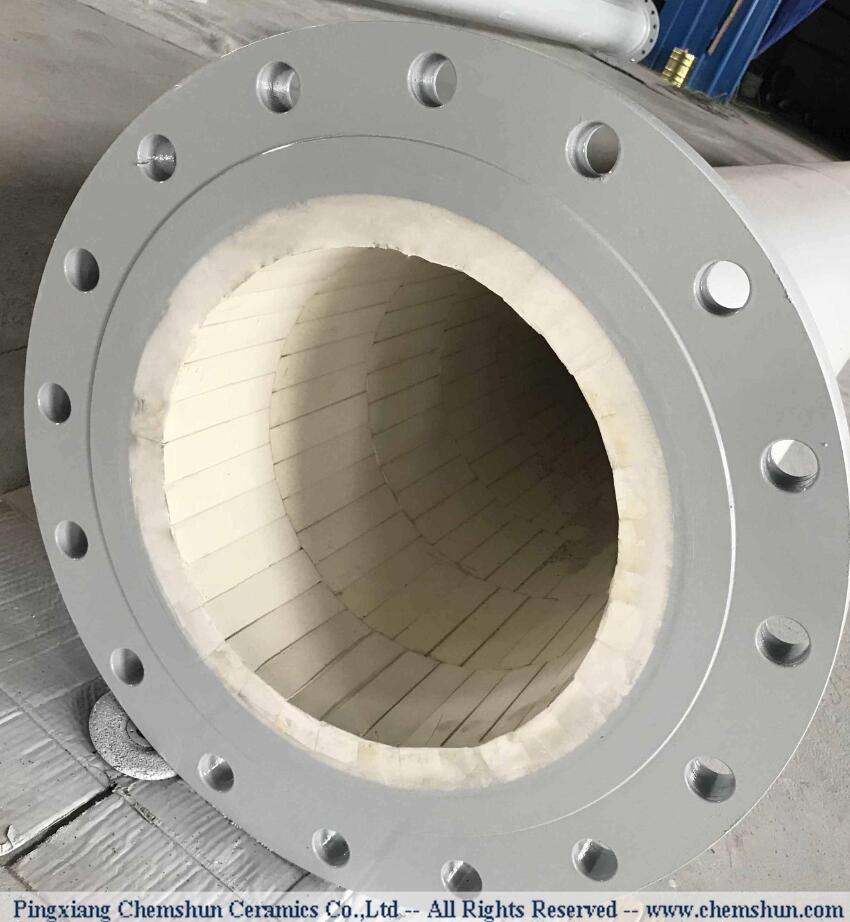

Wear resistant ceramic pipe flanges Introduction

Flange is a disc-shaped part that is very common in piping engineering. Flanges are used in pairs. In wear resistant ceramic pipeline engineering, flanges are mainly used for wear-resistant ceramic pipeline connections. Various flanges can be installed in wear-resistant ceramic pipes that need to be connected. Low-pressure wear-resistant ceramic pipes can use wire flanges, and welding flanges can be used for pressures above 4kg. Flange connection is to fix two wear-resistant ceramic pipes, pipes or equipment on a flange plate, with a flange gasket for sealing between the two flange plates.

The flanges used in wear resistant ceramic pipes are mainly divided into welding flanges and movable flanges:

1. Welding flange: directly welded to the pipe, the flange is fixed and immovable;

2. Movable flange: First insert the movable flange onto the wear-resistant ceramic pipe, and then weld the retaining ring on the wear-resistant ceramic pipe port.

There are many flange standards for the same steel pipe size and thickness: whether the flange is welded or live flange, flange diameter, flange thickness, flange bolt hole center spacing, flange hole number, flange bolt diameter. If it is a welded flange on an elbow, the location of the flange hole must also be determined. If the flange expands, attention should be paid to the size range of the flange sealing ring. It cannot exceed the specifications of the sealing ring, otherwise it will not be sealed.