Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

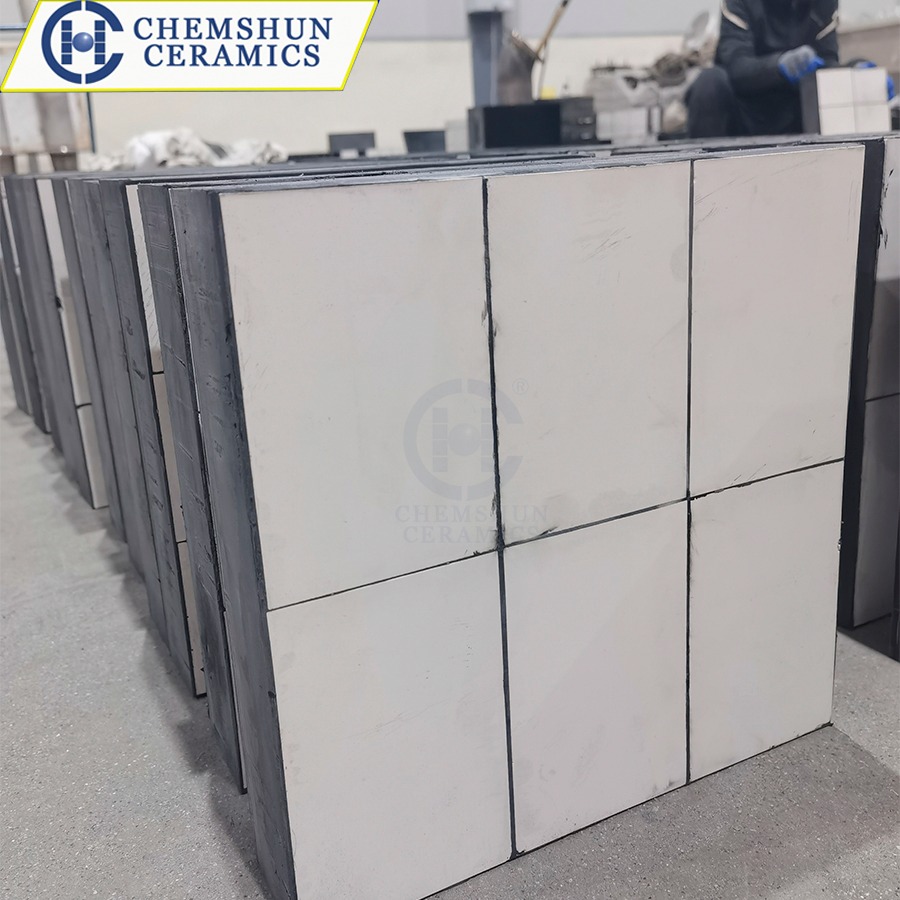

How to improve the impact resistance of wear resistant ceramic linings

As a new type of high-performance material, Chemshun wear resistant ceramic linings are widely used in various industrial equipment due to their excellent wear resistance and corrosion resistance. However, under certain high-impact conditions, the impact resistance of wear-resistant ceramic linings still needs to be improved. This article aims to explore how to effectively improve the impact resistance of wear-resistant ceramic linings.

The main material of wear-resistant ceramic linings is alumina. Although it has high hardness, it is brittle and has weak impact resistance. To address this problem, the following methods can be adopted:

1. Use ZTA ceramics: By adding a certain proportion of zirconium oxide to alumina, zirconium oxide alumina composite ceramics (ZTA ceramics) are formed. Compared with ordinary alumina ceramics, ZTA ceramics have significantly enhanced toughness and greatly improved impact resistance.

2. Ceramic rubber composite: Wear-resistant ceramic liners are mostly used in combination with rubber, ceramics are responsible for wear resistance, and rubber is responsible for impact resistance. By optimizing the vulcanization process and exposing more rubber on the surface of the liner, the overall impact resistance can be effectively improved. However, it should be noted that rubber cannot withstand high temperatures, and this method is suitable for normal temperature environments.

3. Design spherical protrusions: Make hemispherical protrusions on the ceramic surface, and use the unique mechanical properties of the protrusions to evenly disperse the impact force on the liner, reducing the possibility of the liner being broken by impact.

In summary, improving the impact resistance of wear-resistant ceramic linings can be achieved by using Chemshun ZTA ceramics, ceramic rubber composites, and designing spherical protrusions. In practical applications, it is necessary to select appropriate improvement strategies according to working conditions to achieve the best impact resistance effect. The implementation of these methods will help to increase the service life of wea resistant ceramic linings, reduce maintenance costs, and provide strong guarantees for the stable operation of industrial equipment.