Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

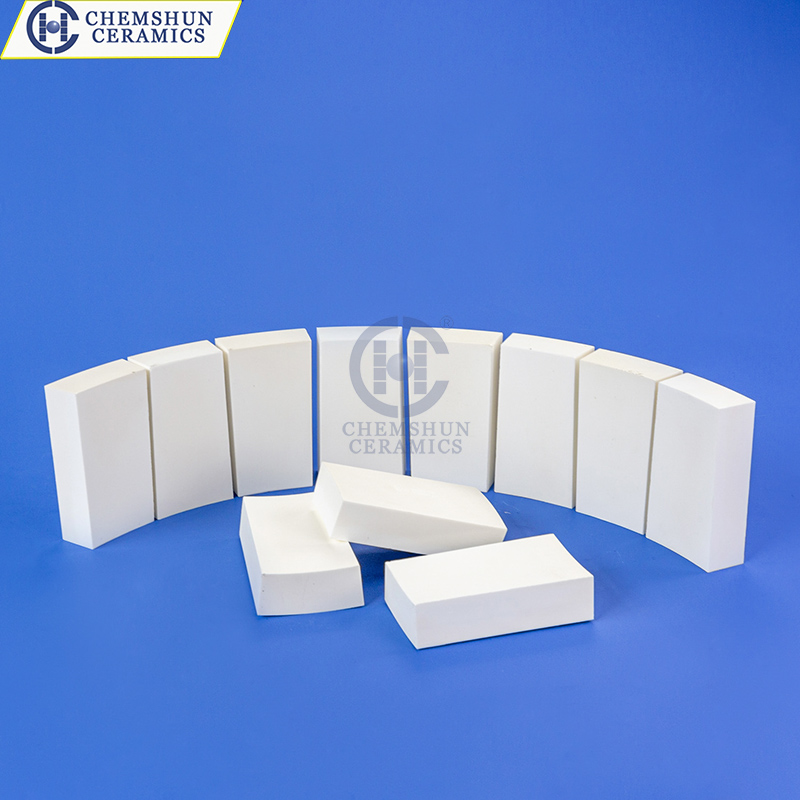

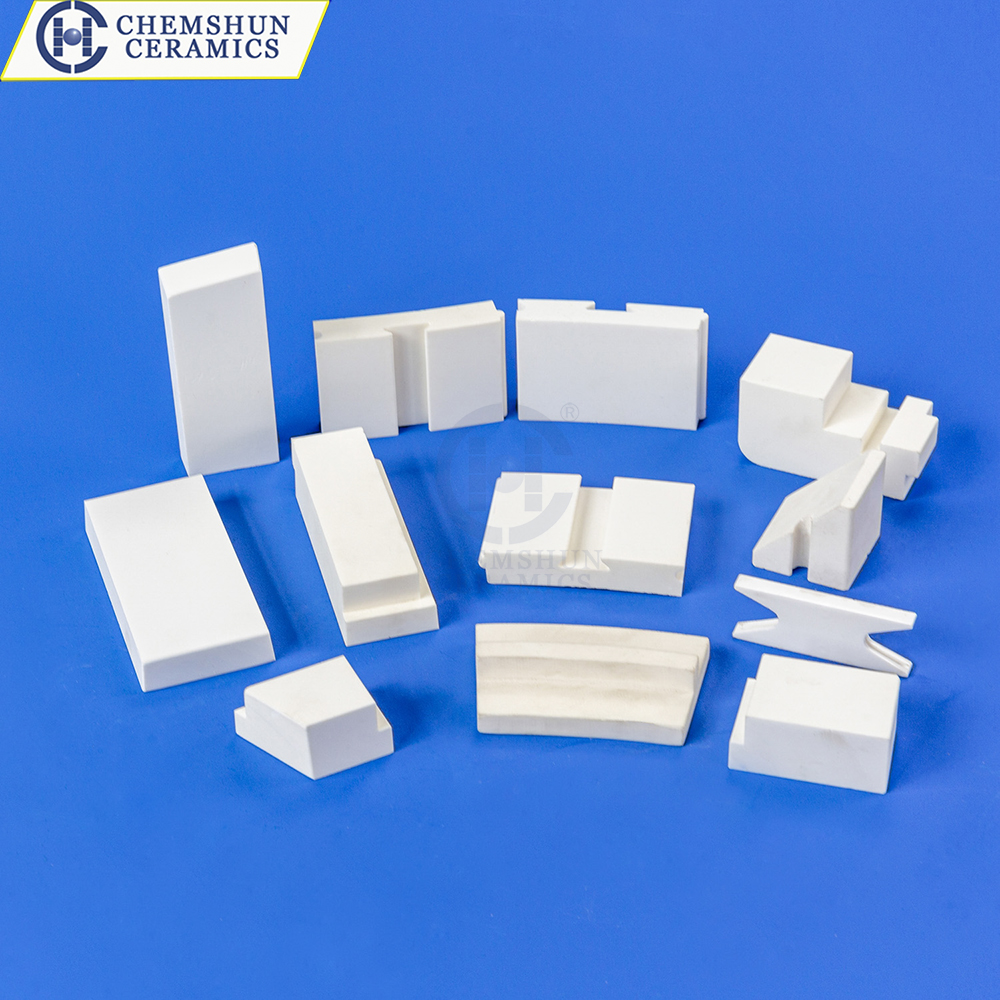

Where can wear-resistant ceramics be used in the mining industry?

There are many places where wear-resistant ceramics can be applied in the mining industry. Here are some common application areas.

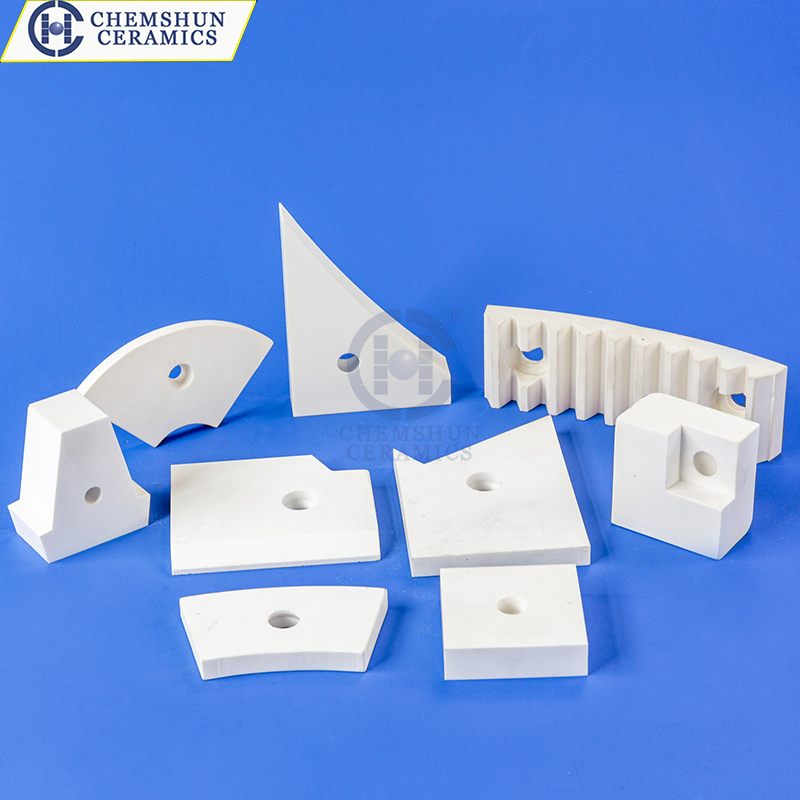

Crusher parts: wear-resistant ceramics can be used for various parts of the crusher, such as lining plate, hammer head, tooth plate, jaw plate, etc.

The elevator needs to be sealed: the mine elevator needs to rotate in the work, and produce friction with the wire rope, etc. Wear-resistant ceramics can be used for the seal of the elevator to improve its service life.

Excavator parts: wear-resistant ceramics can be used for various parts of the excavator, such as bucket teeth, tooth base, scraper chain, etc., which can improve the work efficiency of the excavator.

Wear-resistant parts of transport vehicles: mining transport vehicles need to withstand the harsh mining environment, wear-resistant ceramics can be used for wear-resistant parts of vehicles, such as drive shafts, sprockets, frames, etc., to improve their service life and safety.

The application of wear-resistant ceramics in the mining industry is mainly to improve the service life of equipment, reduce maintenance costs, improve production efficiency, and also enhance the safety of equipment operation. When choosing wear-resistant ceramic products, it is recommended to select the appropriate product type and specifications according to the actual application environment and conditions to ensure that its performance can be fully played.