Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

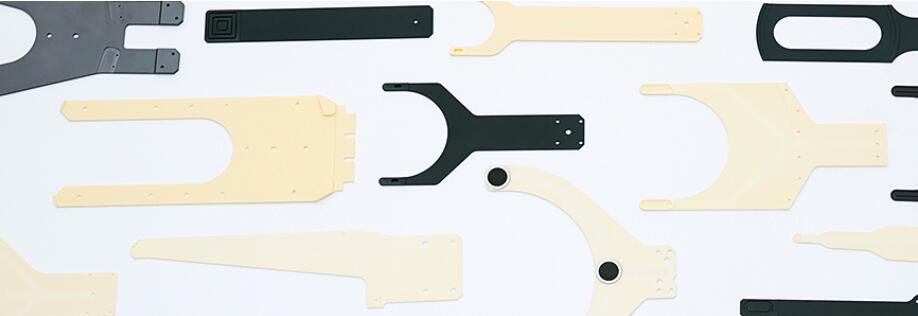

What is a high purity alumina ceramic handing arm?

High purity alumina ceramic handing arm /ceramic end effector is installed on wafer handing robot or "end effectors" and used to carry silicon wafers into or out of cassettes or process chambers. It is also known as semiconductor ceramics, and the main production materials include 95% to 99.9% aluminum oxide. High purity alumina ceramic mechanical arm is a product that must be used in the wafer transfer process, and the requirements for materials and processing accuracy are very high.

In the CMP device, the wafer is first picked up from the wafer box by the robot wall, and then precisely positioned on the platform below the polishing head. The polishing head usually has the function of vacuum adsorption, when the wafer is placed under it, the polishing head moves down, and the wafer is firmly adsorbed on the polishing head through vacuum adsorption. Once the wafer is secured, the polishing head moves the wafer onto the polishing pad for the polishing process.

In order to avoid wafer contamination, it is generally handled in a vacuum environment, and the handling arm needs to be resistant to high temperature, wear resistance, and the hardness also needs to be very high. Alumina ceramics and silicon carbide ceramics have dense,high hardness, high wear resistance physical properties. As well as good heat resistance, excellent mechanical strength, high temperature environment still has good insulation, good corrosion resistance and other physical properties, is used to make semiconductor equipment mechanical arm excellent material.