Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

What is Abrasion resistant ceramics?

Ceramics are inorganic non-metallic materials. According to different raw materials, they can be divided into ordinary ceramic materials and special ceramic materials. Ordinary ceramic materials use natural clay or quartz as raw materials and are sintered at high temperature. They have certain special properties to suit each Kind of need.

The granular ceramic green body was sintered in a high-temperature electric furnace at 1650 degrees Celsius, and various shapes of ceramics were formed after 72 hours. High hardness, light weight, good heat resistance, and corrosion-resistant ceramics are widely used as abrasive ceramics.

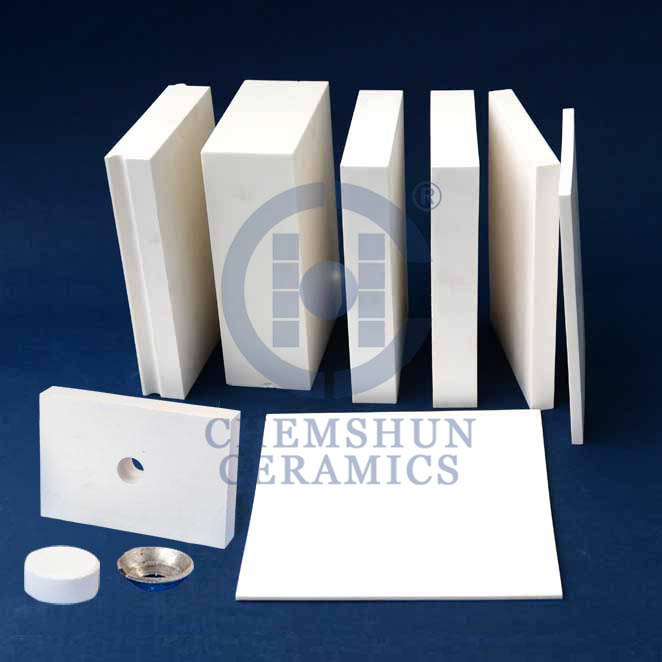

Chemshun Ceramics is a manufacturer of abrasion resistant ceramics. Various wear-resistant ceramics include alumina ceramics, toughened alumina ceramics, zirconia ceramics, and silicon carbide ceramics. Each wear-resistant ceramic has its own advantages and disadvantages. Therefore, customers and manufacturers must conduct sufficient analysis and research on the working conditions of ceramic use. If the use conditions are not met, the ceramic will not achieve the expected wear resistance. The use environment that generally affects the wear resistance of ceramics includes:

1: Operating temperature range and changes

2: Corrosive medium

3: Force condition

4: Impact strength of transmitted material

Wear-resistant ceramics are widely used in bulk material handling systems, such as cement industry, ports, coal industry, steel mills, mines, etc. Different equipment accessories require different shapes of ceramics. Chemshun Ceramics has ceramic plates, ceramic tubes, rubber-ceramic composite plates, etc. At the same time, various special-shaped parts can be customized and processed according to needs.