Top articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

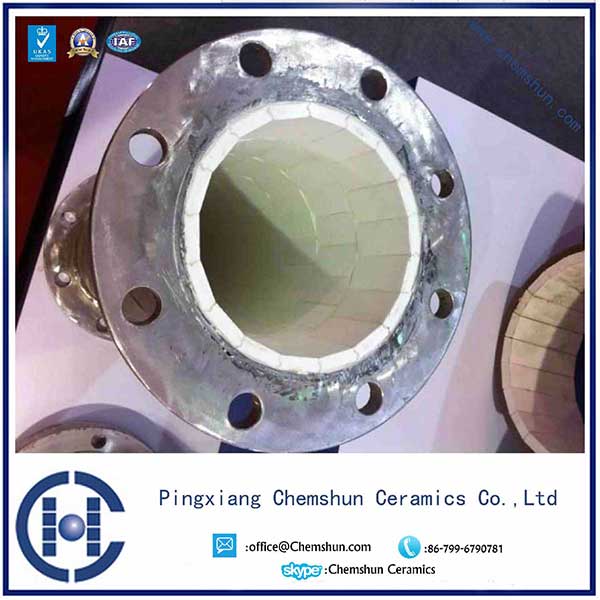

Wear damage Analysis about material Handling elbow pipe

Although the material handling elbow pipe has selected wear resistant ceramics liner, but it is easily wear damage part during abrasiveness materials transportation , The main reasons are: when the material passed through the pipe, then crashed into the outside of the inner wall of the pipeline due to the centrifugal force and inertia . Portion of the particles slide along the inner wall of the pipe outer lateral; another part of the particles reflect from the inner wall of the pipe outer lateral into the inner wall of the inboard pipe, repeated movements like this; material after several collisions, in the middle of the outer wall of circular cross-section of the elbow, will cause pits. by analysis elbow surface friction is caused by the friction of the particles , also is due to organization crushing and detachment of wear resistant ceamic lined pipe by particles hitting the surface ,therefore, the material impact and friction to the wall is the main reason of bend elbow wear damange .

The main reasons are: when the material passed through the pipe, then crashed into the outside of the inner wall of the pipeline due to the centrifugal force and inertia . Portion of the particles slide along the inner wall of the pipe outer lateral; another part of the particles reflect from the inner wall of the pipe outer lateral into the inner wall of the inboard pipe, repeated movements like this; material after several collisions, in the middle of the outer wall of circular cross-section of the elbow, will cause pits. by analysis elbow surface friction is caused by the friction of the particles , also is due to organization crushing and detachment of wear resistant ceamic lined pipe by particles hitting the surface ,therefore, the material impact and friction to the wall is the main reason of bend elbow wear damange .

Abrasion damange of handling materials is inevitable, but design and installation ideal wear resistant ceramis is necessary for industrial company, welcome to consult pingxiang chemshun ceramics co.ltd , which is wear resistant ceramics design,manfacturer,installation experts, high quality abrasive materials will be offered for your machine wear protection .