Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Wear-resistant ceramics can be applied to draught fan to prevent wear

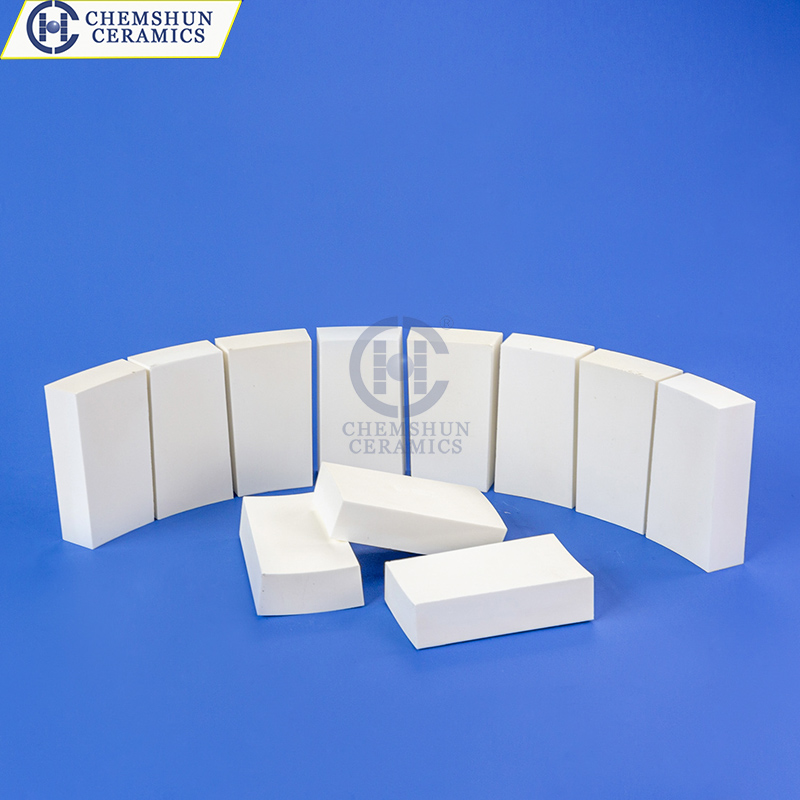

Wear-resistant ceramics are mainly used for anti-wear on the surface of industrial equipment, among which wear-resistant ceramic patches are widely used. It can be applied to the fan equipment to help reduce the wear rate and extend the service life of the equipment.

The long-term operation of the fan equipment, serious wear may lead to efficiency reduction, noise increase, vibration increase and other problems. If the wear is severe, the draught fan may need to be replaced, so it is very important to increase the anti-wear ability of the draught fan. Wear-resistant ceramic patches are an effective anti-wear solution that can be attached to fan equipment to protect the surface of the equipment and improve anti-wear ability.

Specific construction steps are as follows:

1. Clean the surface of the fan blade and ensure that the surface is clean and free from contamination.

2. Select the appropriate size of wear-resistant ceramic patch according to the size and shape of the fan blade.

3. Use ceramic special glue according to the proportion, apply on the surface of the ceramic, and then glue the ceramic patch on the device. In the case of high temperature conditions, high temperature ceramic glue is required. Choose the glue reasonably according to the working condition.

4. The pasted tiles need to be cured for about 8 hours before they can be touched; Check whether there is a lack of glue, and apply glue. Make sure the tiles are tightly glued to the device.

It should be noted that when using wear-resistant ceramic patches, high-quality products and professional construction teams should be selected to ensure its long-term anti-wear effect. In addition, it is also necessary to regularly check and maintain, according to different degrees of wear, choose the appropriate anti-wear program.