Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to Choose Wear Resistant Ceramic Liner ?

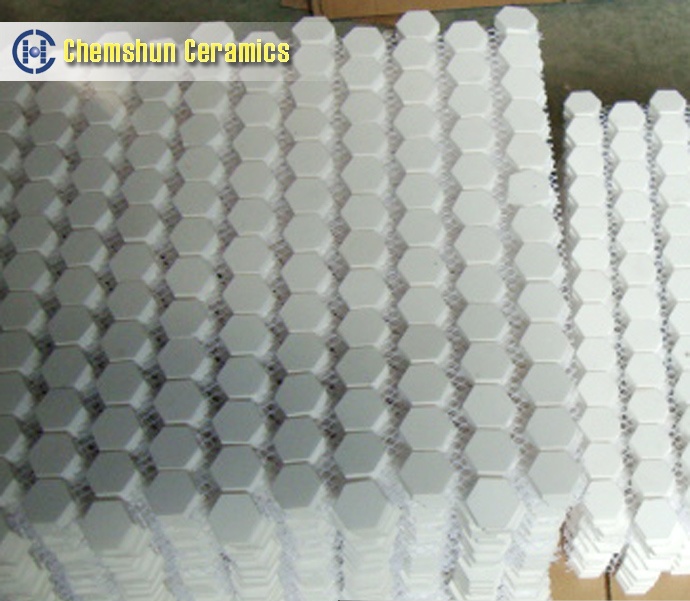

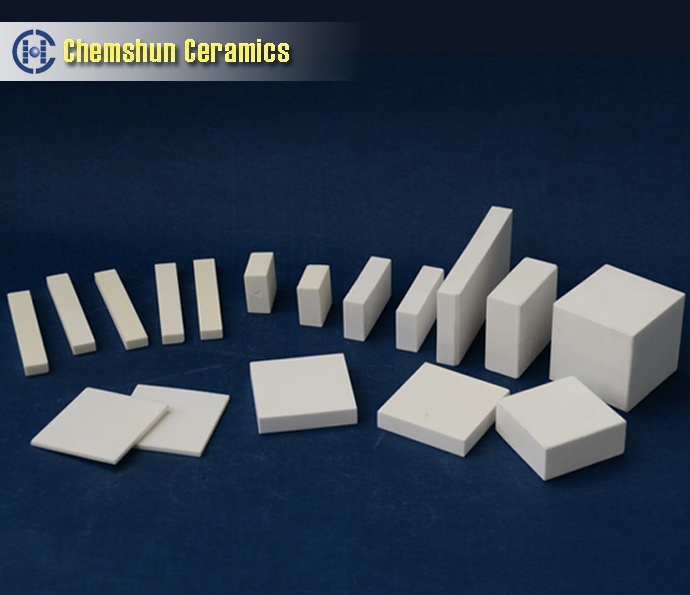

The wear resistant ceramic liner is a special ceramic liner fired at a high temperature. The wear-resistant ceramic liner has a wide range of uses in the market, which is different from the ceramics used in people's daily life. From the perspective of production materials, a large number of industrial materials and metals are used in the production process. Because of these materials and special manufacturing technology, ceramic linings have the characteristics of wear resistance and high hardness. So, how should we choose wear-resistant ceramic linings?

First,from the perspective of hardness.

Wear-resistant ceramic linings are mainly used in various mechanical equipment in the factory, and the ceramic linings used by different mechanical equipment are also different. Choosing the appropriate ceramic lining from the hardness mainly depends on which part of the mechanical equipment is placed. As far as the cutting machine is concerned, the harder the wear-resistant ceramic lining used near the workpiece is. The hardness of the ceramic lining is slightly lower in the middle or tail of the mechanical equipment.

Second,from the perspective of the firmness and heat resistance of the ceramic linings.

Wear-resistant ceramic linings can also be used in engineering equipment such as steel smelting. In these types of machinery factory equipment, the requirements for heat resistance and robustness are very high. Because these mechanical equipment often work in high-temperature environments, if a part of the mechanical equipment is not heat-resistant, people safe cannot be guaranteed during use, and the life of the mechanical equipment will be shortened.

Chemshun could afford customers the optimum Wear-resistant ceramic linings accommodate the detailed equipment wear protection demand. It adapts all the ceramic linings totally to meet the application.