Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

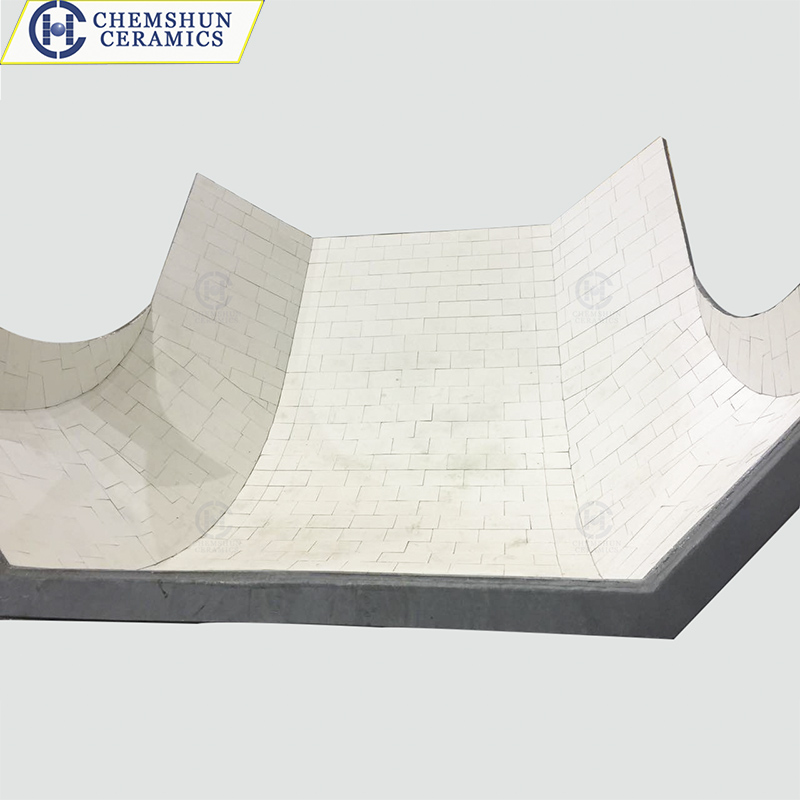

Use Wear-resistant Ceramic Liner to Solve the Problem of Chute Wear

In the steel, power plants, cement and other industries of the factory equipment, are used to chute, chute long-term by the flow of material wear impact, chute surface easy to wear serious. In order to solve the wear problem of the chute, it is necessary to find a high-hardness material that can truly resist wear.

Wear-resistant ceramics are high hardness materials that can be used to solve the problem of chute wear. Wear-resistant ceramics are made of aluminum oxide, which is sintered in a high temperature kiln of more than 1700 degrees. Wear-resistant ceramics have high hardness and high strength, the hardness reaches more than HRA85, and the wear resistance is 271.5 times that of fierce steel, so it has excellent wear resistance. In addition, wear-resistant ceramics can resist acid and alkali corrosive substances and can be used in the chemical industry.

To solve the problem of chute wear, wear-resistant ceramic liner can be used. The installation of wear-resistant ceramic liner is simple, and it can be pasted to the inner wall of the chute with special ceramic glue to make it a protective layer of the chute and resist the erosion of materials. Ceramic lining plates with holes can also be used to double fix by welding and gluing, which makes the process more firm. The surface of the wear-resistant ceramic liner is smooth, which will not cause the phenomenon of chute blocking and sticking. Wear-resistant ceramics are an effective method to solve the problem of chute wear.