Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

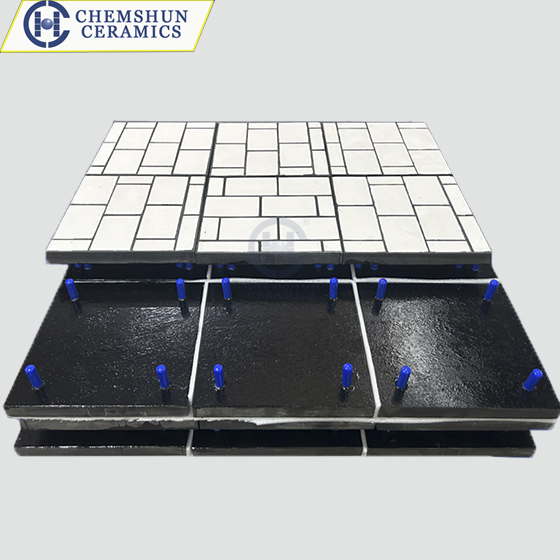

The three-in-one ceramic liner can be applied to the discharge hopper

In the steel plant, the hopper is very vulnerable to wear and tear equipment, in the past is the use of wear-resistant steel, but due to the continuous transport of coke, slag and other materials during the operation process, the hopper bears a lot of impact and friction, very easy to damage, resulting in wear-resistant steel will be damaged soon after use, coupled with frequent maintenance will cause more costs, seriously affecting the production schedule.

In order to solve the wear problem of the discharge hopper, the design structure of the discharge hopper has been optimized by Chemshun Ceramics, and the scheme of three-in-one ceramic liner has been adopted to solve the wear problem of the lower hopper.

The three-in-one ceramic lining plate is composed of alumina ceramic, rubber and steel plate, and is made by rubber injection hot vulcanization process. It has strong wear resistance and impact resistance, can withstand greater pressure and friction, is very suitable for the transport of large materials on the equipment. The toughness of rubber can not only reduce the impact of materials, but also reduce noise. The back of the ceramic composite liner has bolts for easy installation and can be customized to the size of the equipment.

In the steel mill environment, the material in the discharge hopper may be corrosive, and the three-in-one ceramic liner has good corrosion resistance, can resist the erosion of corrosive media, and protect the discharge hopper from corrosion damage.

Three-in-one ceramic liner has excellent wear resistance, can effectively resist the material wear in the discharge hopper, extend the service life of the discharge hopper, reduce equipment maintenance and downtime, thereby reducing production costs, improve production efficiency, is a good anti-wear, anti-impact material.