Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Reasons and Solutions for Industrial Ceramic Tile Lined the Surface of the Magnetic Separator Drum to Fall Off

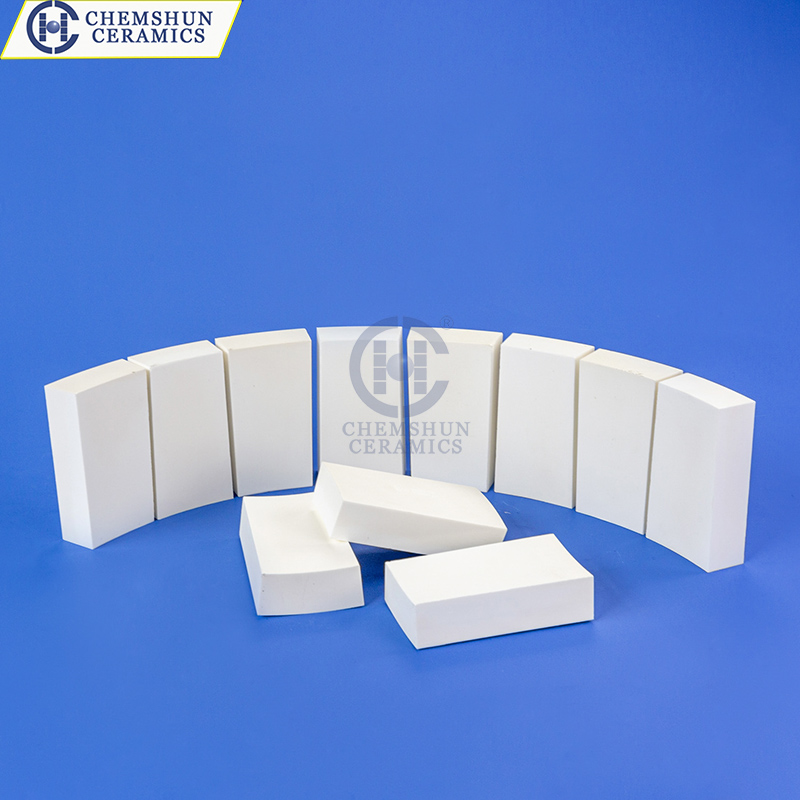

Alumina ceramic tile liner are widely used in mining, cement, electric power, metallurgy, mineral processing and other fields due to their excellent wear resistance. The anti-wear technology of pasting wear-resistant ceramic sheets on the surface of the magnetic separator drum is also

It has been verified and recognized by the market. However, due to the recent fierce market competition and price wars, some manufacturers have provided inferior ceramic sheets and adhesives to customers, causing customers to use phenomena occur during the process. It seriously affects the normal operation of enterprises and has a significant impact on the credibility of the entire industry. In this regard, we have analyzed several reasons for customer construction failure. We hope that our customers and friends can pay attention to these points and avoid unnecessary losses to themselves.

1. The thickness of the wear-resistant ceramic sheets is uneven, some are 2mm, and some are 4mm. In the process of pasting the ceramic sheets, due to the whole-page pasting, the wear-resistant ceramic sheets and the metal substrate cannot be closely adhered to each other in some parts. together, but there is a gap in the middle; resulting in weak bonding and easy falling off during use. Even if the wear-resistant ceramic sheets can be compacted one by one, the result will be that the roller after pasting

The surface is uneven, which causes uneven flow of materials during use and cannot achieve a good mineral processing effect.

2. Quality problems of wear-resistant ceramic sheets: The wear-resistant ceramic sheets have missing corners and cannot form a tight fit. The missing parts are quickly worn through during use;

3. The alumina composition of the ceramic sheets is not up to standard and the wear resistance is insufficient. As a result, the service life cannot meet the requirements.

2.There is a problem with the quality of the ceramic glue selected. Some manufacturers directly recommend adhesives to customers without asking about the working conditions. Some cheap glues on the market can often be used in pipes, chutes and other places where the impact force is not large, but due to magnetic During the operation of the selection machine, the material falls vertically from a high place and is subject to a large impact force. If the adhesive is not tough enough, it will be shaken off.