Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

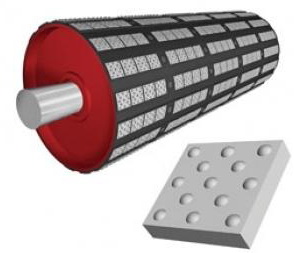

Pulley lagging ceramics installation process

Pulley lagging ceramics installation process (2)

--- Attention paid during installation

Chemshun Ceramics stated the installation process of ceramic pulley lagging ,here the attentions during installation are illustrated .

1) Smooth processing of pulley: check whether there is dump or defect on the surface pulley , keep welding gap smooth ,to ensure rubber sheet sticked glidingly

2) Mechanical descaling: Decal and de rust the pulley surface With Angle grinder or Sandblasting machine until the original metal color appeared

3) Rubber sheet polished : with Tungsten steel dish for burnish

4) After de rusting, With acetone or high grade clean gasoline clean

equipment surface to remove surface dirt and grease.

5) Adhesive prepared : strictly according to correct adhesive proportion & temperature proportion , mixed equably for good adhesive strength

6) Bottom adhesive daubed equably , not too thick

7) First adhesive daubed after bottom glue complete become dry , at the same time , rubber sheet is daubed first adhesive .

8) Second adhesive daubed after first adhesive complete become dry enough

9) Splice rubber sheet and pulley quickly after second adhesive become half dry

10) Donn’t move after complete splicing , and beat with hammer ,then mending gap

Chemshun Ceramics supply Al2O3 ceramic tile for pulley lagging ceramics with square or rectangle cermic tile. welcome to inquiry by office@chemshun.com