Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

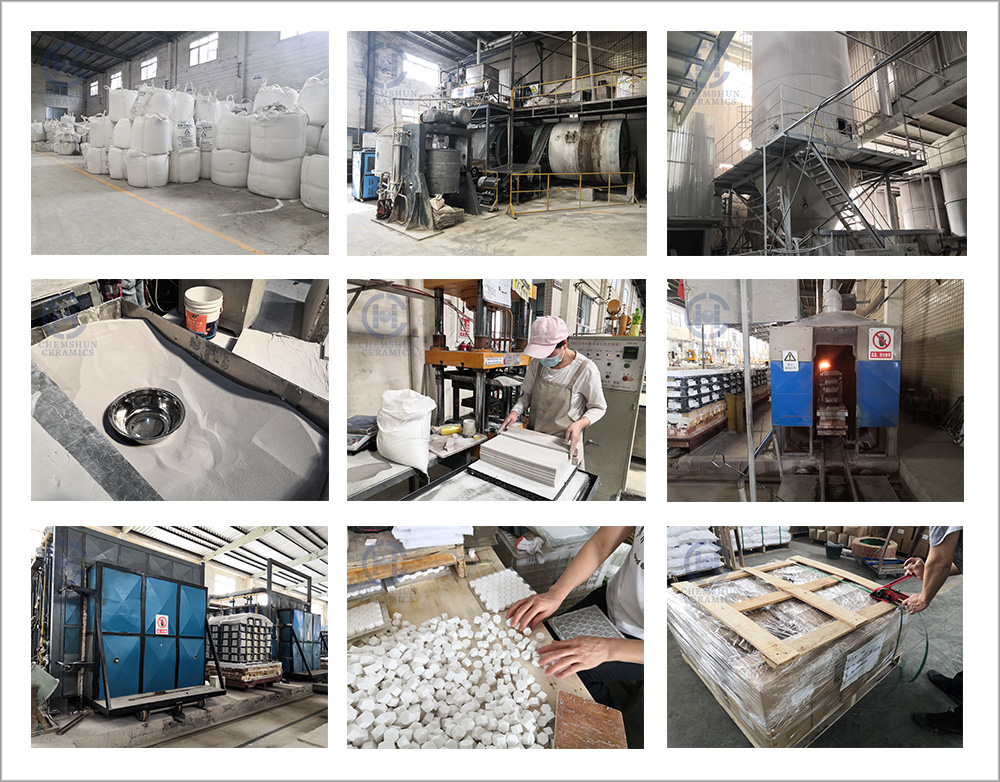

Production Steps of Wear Resistant Alumina Ceramics

Wear resistant alumina ceramics are the most detailed and widely used industrial ceramics. Due to their own properties, especially high temperature performance and chemical properties, they are excellent and stable. They are widely used in thermal power, steel, smelting, and mining. In the transportation system of powder or fluid in other industries, traditional metal and organic materials are gradually replaced.

The following introduces the production steps of Chemshun wear resistant alumina ceramics:

1.Through the company’s formula, high-quality powders such as fine alumina and kaolin are mixed,and then put into a ball mill, and the raw materials are ball-milled to ultra-fine particles with a particle size of 1.8um;

2.After detecting the slurry fineness, slurry particle size, moisture content, and the time of passing the flow meter with professional equipment, put the qualified slurry into the slurry tank;

3.The slurry in the slurry tank is sucked into the spray drying tower through the servo system for drying and granulation;

4.Use 40 mesh, 60 mesh, 100 mesh, 120 mesh, and 140 mesh sieves to sieve at one time to gradate the particles and put them in the stale warehouse for homogenization;

5.The body is pressed into the desired shape by pressure molding;

6.After drying, it is fired in a kiln at 1555℃, and finally selected and packed into storage.