Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

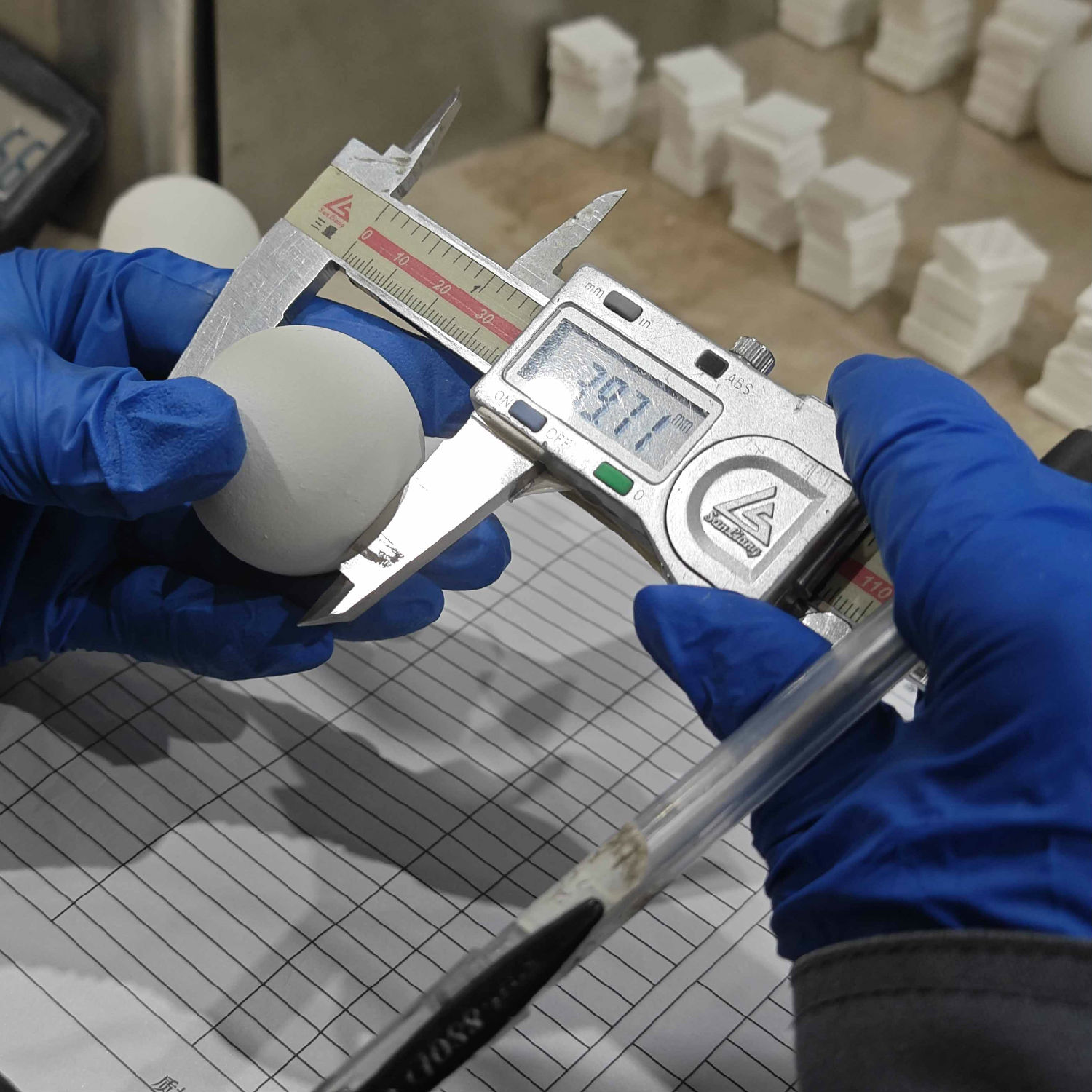

Factors affecting the wear resistance of alumina grinding balls

Alumina grinding balls are also called high-alumina ceramic balls, alumina wear-resistant balls, and inert alumina balls. The production process adopts isostatic pressing, and some small balls adopt the artificial ball method; the raw material is calcined alumina.

Powder, with strong wear resistance, improves the stability of the product and reduces surface wear; the calcination temperature of the product reaches 1600°C or higher, and the holding time exceeds 10 hours.

Alumina grinding balls have the characteristics of high hardness, high density, small wear, smooth surface, and corrosion resistance. It is an ideal anti-wear grinding medium for grinding glazes, billets and various powder materials. Used in ceramics, cement, coatings, refractory materials, inorganic mineral powder and other industries, ball mill lining and grinding media.

Alumina grinding balls are an important grinding media in the grinding industry market and are also the most demanding grinding media among ball mill grinding materials. Alumina grinding balls undoubtedly have better grinding and wear resistance, so what are the factors that affect alumina grinding balls?

First of all, it is very important to choose the raw material AI2O3 for alumina grinding balls. The choice of AI2O3 directly affects the final product quality and grinding performance of alumina balls. The particle size of the AI2O3 raw material will also directly affect the wear resistance of the alumina grinding ball.

The second is to select appropriate sintering aids to reduce the sintering temperature of aluminum hydride grinding balls through sintering aids, thereby improving the microstructure of the ceramic and the mechanical properties of aluminum hydride grinding balls, and then improving the wear resistance of alumina grinding balls.

Furthermore, the formation process of alumina grinding balls. There are two types of alumina grinding balls on the market: roll forming and isostatic pressing. Rolling molding and isostatic pressing molding technology have changed the shortcomings of other moldings such as hollowness and layering, which are uneven. It is necessary to use suitable raw materials and mature molding technology to ensure good sintering characteristics and improve the wear resistance of alumina grinders.

The firing stage of alumina grinding balls is also very important. When the appropriate sintering temperature is not well grasped, for example, the sintering temperature is too high or the longer the holding time, the more crystal growth of AI2O3 will occur, and the liquid phase will increase. This will not only lead to a reduction in the strength of the alumina grinder, but also reduce the wear resistance of the alumina grinding balls.

When a suitable sintering method is adopted, such as low-temperature and rapid combustion, the energy-saving effect will be greatly improved, and the grain growth of the alumina grinding balls is also controlled, thereby improving the strength and toughness of the alumina grinding balls and increasing the number of alumina grinding balls. wear resistance.