Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

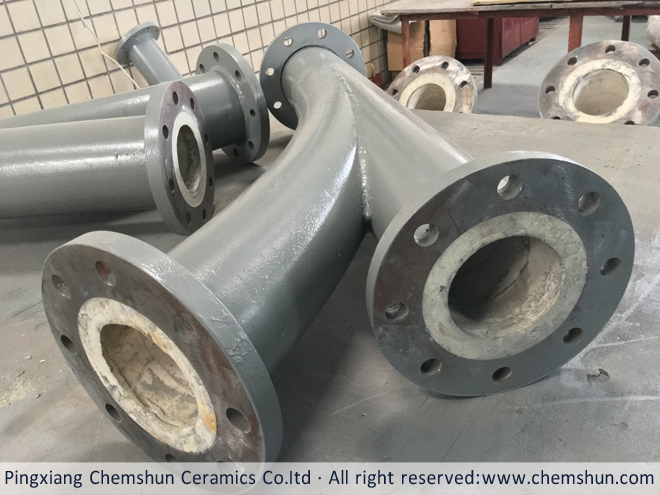

The Design and Manufacture of Wear Resistant Ceramic Pipe

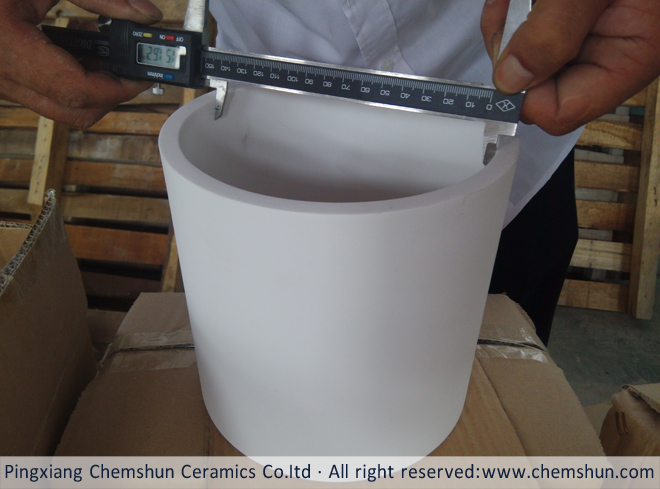

Chemshun wear-resistant alumina ceramic tubes/ pipe is a special kind of wear-resistant pipe. Its design structure is to add a layer of wear-resistant alumina ceramic lining inside the steel pipe. The abrasion resistance and high temperature resistance of Chemshun alumina ceramic pipes are not only much higher than ordinary pipes, but also higher than traditional wear-resistant pipes such as wear-resistant alloy cast steel pipes, cast stone pipes and steel rubber pipes.

The high mechanical properties of chemshun alumina ceramic wear-resistant pipes are the result of the dual effects of ceramic characteristics and manufacturing methods. The inner ceramic layer of the wear-resistant ceramic composite pipeline is 92% and 95% Al2O3 alumina materials. Its hardness is much higher than that of ordinary wear-resistant materials. Its hardness can reach more than 90 rockwell hardness, which is equivalent to the hard tungsten and cobalt gold. Wear-resistant ceramic pipe is made by centrifugation, such corundum and steel layer can form special stress field, after the temperature to 400 ℃ above, as a result of the alumina layer and steel expansion coefficient is different, between generate new stress field, and make both in the balance of a free state, thus wear-resistant ceramic tube has a stable of high temperature resistant ability.

The manufacturing method of wear-resistant ceramic tube also makes it have incomparable thermal shock resistance.The wear-resistant ceramic tube is repeatedly soaked in cold water after the temperature is raised to 900℃, and there will be no cracks. This means that the inner layer of the wear-resistant ceramic tube can withstand temperature changes and can be connected and installed by welding.

Chemshun Ceramics Wear resistant ceramic tube has excellent performance with good price, which are used widely in conveying system especially in the process of Pneumatic conveying system. If you need more information, welcome to contact with us by email office@chemshun.com or calling us +86-799-6790781, 0086-158-7995-7696.