Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to solve the temperature problem between the grinding disc on the plane grinder and the workpiece

How to solve the temperature problem between the grinding disc on the plane grinder and the workpiece

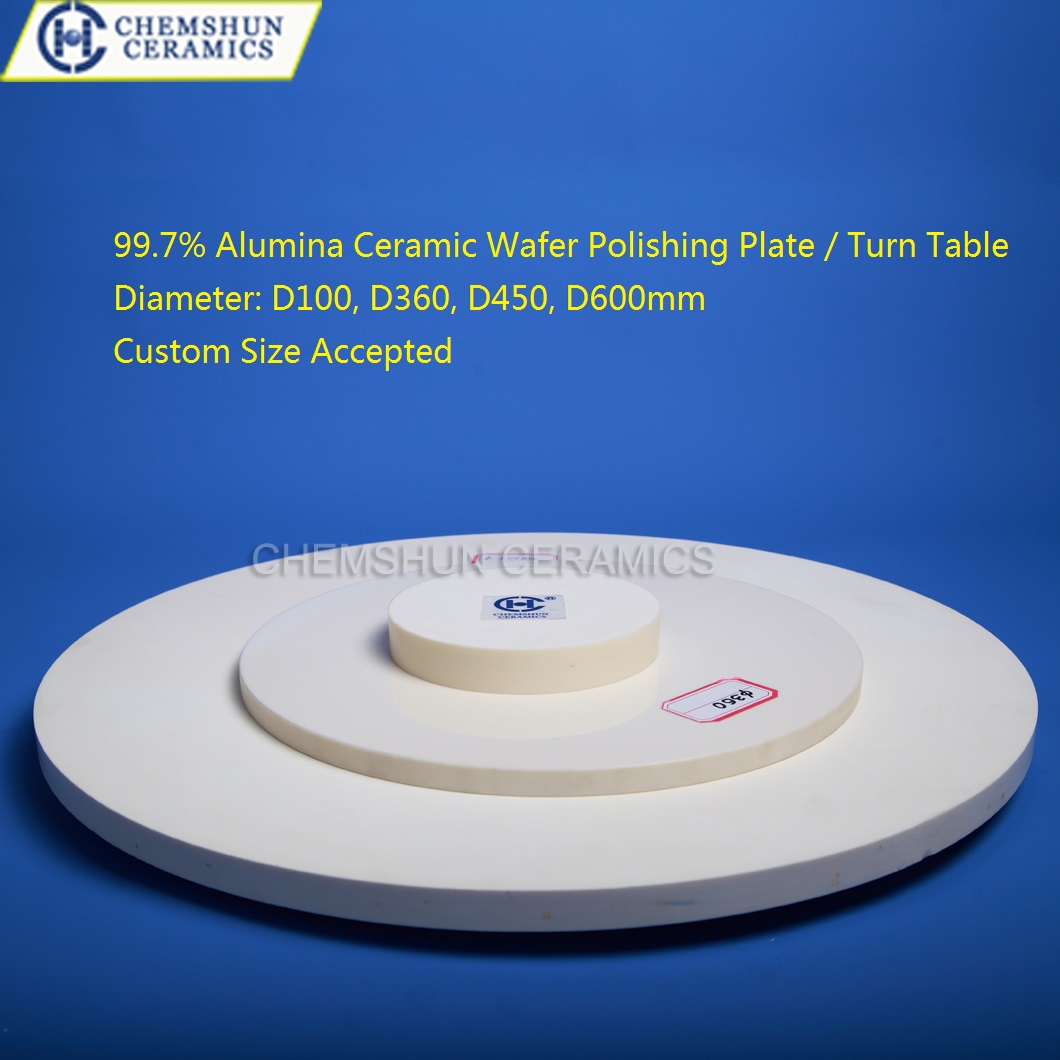

The surface grinder is a precision grinding device. The product to be grinded is placed on the grinding disc. The grinding disc rotates counterclockwise. The workpiece rotates by itself. The workpiece is pressed by gravity compression. The workpiece and the grinding disc are rotated relative to each other to achieve the purpose of grinding. ; The disc repairing machine adopts hydraulic suspension guide rails, and the diamond disc is used for precision trimming of the grinding disc, so that the grinding disc can obtain precise flatness. It is widely used in LED sapphire substrates, optical crystal materials, hardware parts, molds, light guide plates , Valve plate, hydraulic pressure, stainless steel and other single-side grinding materials.

The temperature between the grinding disc and the workpiece during the processing of the plane grinding machine is a problem that needs to be solved.

The method currently used is to cool the grinding disc. We added a fixed cooling device to the surface grinder. When the machine is started, the cooling device will also start.

The surface grinder manufacturer analyzes that when the grinding disc reaches a certain temperature, the cooling liquid in the cooling device will flow into the grinding disc and the workpiece to achieve the purpose of cooling at the same time, to ensure that the quality of the workpiece is not damaged, and At the same time, these cooling fluids can also help to achieve the grinding effect as soon as possible.