Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

what material is used to make bulletproof vests

Steel plate is the earliest material used in hard bulletproof body armor panel , which greatly improves the protection level of soft body armor, but the protection ability is limited, it can only defend against the attack of lead-core bullets and ordinary steel-core bullets, and it is too heavy and easy to attack. Disadvantages of ricochet. Compared with the steel plate, the performance of the ceramic material has been improved, the light weight and density are less than 1/2 of the steel plate, and there is no ricochet phenomenon.

Among the commonly used bulletproof ceramics, B4C, Si3N4, SiC, have outstanding bulletproof performance, but the price is high, while Al2O3 military armor ceramics have the advantages of low price, mature technology, easy size control, low sintering temperature, and easy mass production. Universal material

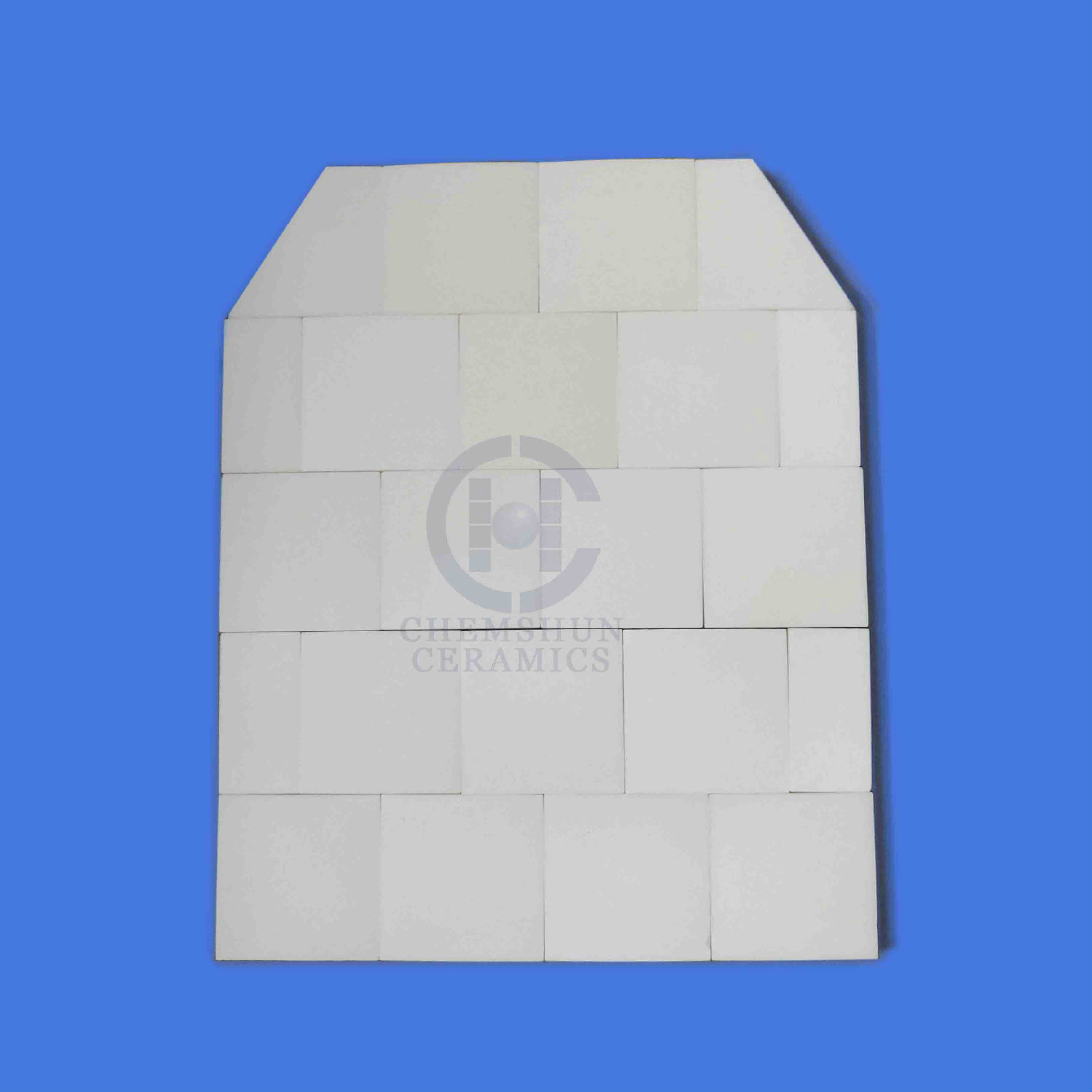

Pingxiang Chemshun Ceramics is a professional manufacturer of alumina bulletproof body vest ceramics. The company mass-produces protective ceramics to provide safety protection for soldiers. The company's common bulletproof ceramic specifications include:

Commonly used bulletproof ceramic sheet specifications:

50*50 square (thickness 4.5~10mm)

50*50 arc surface (ID370~400)

Hexagonal plane (side length 21mm) half piece, bevel (25*50)

Alumina ceramics can be used as ballistic protection due to their high hardness, high strength and chemical inertness in many environments. When metal body armor resists the impact of the warhead, the metal material will plastically deform and absorb energy, while the alumina ceramic has almost no plastic deformation, and relies on its own high strength and high hardness to passivate or even break the warhead, and the ceramic surface is crushed at the same time. And the hard fragment area absorbed the energy of the high-speed warhead. Therefore, the application of advanced ceramics in armor systems is very attractive, and it has become a kind of protective armor widely used in body armor, vehicles and aircraft.