Top articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

Your browsing history

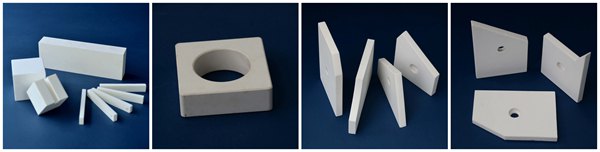

Alumina wear-resistant ceramic is used widely and is introduced

Abstract: the alumina wear resitant ceramics is the most widely use of one of the ceramic material, it can be used as the machine and equipment manufacture of corrosion resistant material, chemical corrosion materials in the professional, electrical and electronic technology of thermal insulation materials, high temperature resistant materials and technologies in the aerospace, defense, etc to some of the special material.

Aluminum oxide wear resisting ceramics is a kind of widely used ceramics.Because of its superior performance, has been more and more widely applied in modern society, satisfied the need of daily and special performance.

1. The hardness The determination of the Shanghai institute of ceramics, the rockwell hardness of HRA80-90, hardness is second only to diamond, far more than wear resistance of wear resistant steel and stainless steel.

2. Excellent wear resistance The determination of central south university institute of powder metallurgy, its wearability is equivalent to 266 times of manganese steel, 171.5 times of high chromium cast iron.According to our customer for more than a decade, under the same conditions, can prolong the service life of equipment more than ten times at least.

3. Light weight Its density is 3.5 g/cm3, only half as much as that of the steel can greatly reduce equipment load.Alumina products molding method can be used in general method, such as dry method, grouting method, pressure casting, extrusion, membrane method, etc.In recent years at home and abroad and develop aluminum oxide wear resisting ceramics filter shaping, direct injection molding of solidification and gel injection molding, centrifugal injection molding molding technology with solid free molding method.Different products shape, size, complicated shape and precision of the products need different molding methods.