Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Alumina Wear-resistant Ceramic Pipe - A High Quality Choice for Pneumatic Conveying Pipes

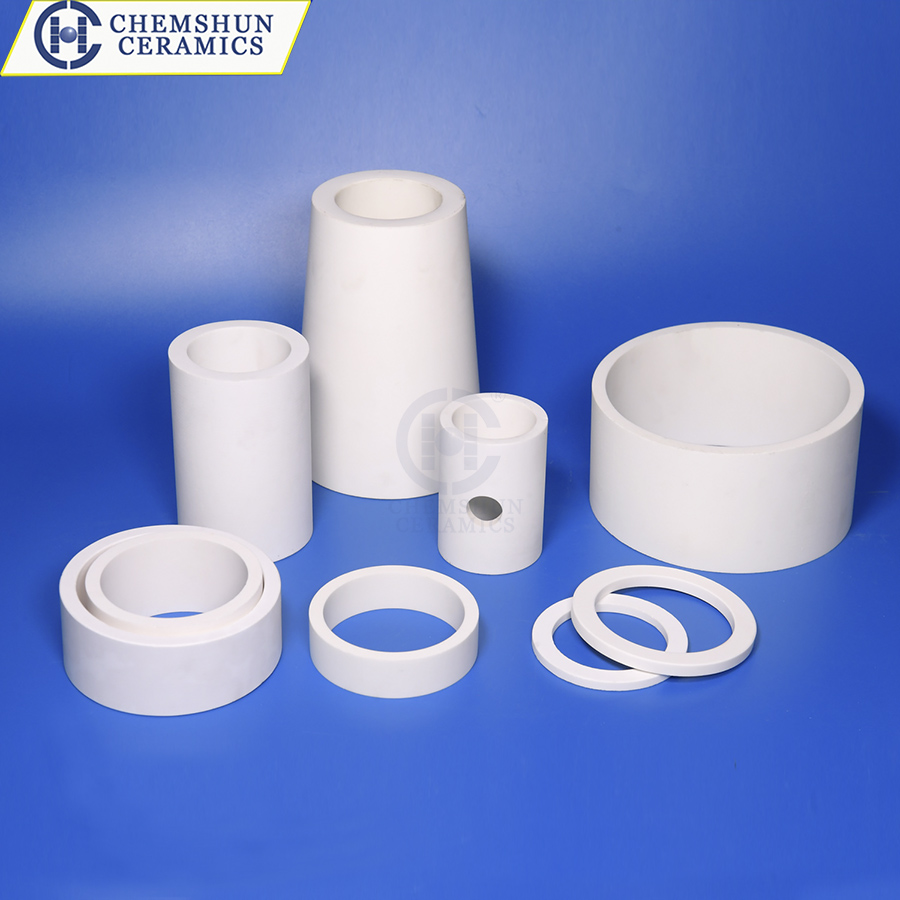

Wear-resistant ceramic tube is a kind of alumina ceramics, according to the shape and use of different can be divided into ceramic straight pipe, bend pipe, conical pipe, three-way porcelain pipe, variable diameter ceramic pipe, ceramic pipe with holes, etc.

There are a variety of forming methods for alumina ceramic pipes, the most common of which are dry pressing and isostatic pressing. After the ceramic pipe is formed, it is processed by lathe to the appropriate size and made into various shapes. Wear-resistant ceramic pipe has the characteristics of wear resistance, corrosion resistance, high temperature resistance and high mechanical strength, and the high hardness makes the ceramic tube more wear-resistant than other anti-wear materials.

Alumina ceramic pipe and steel parts combined, can be made of integrated wear-resistant ceramic pipe. The surface of the ceramic tube is coated with ceramic special glue, and then installed on the inner wall of the steel pipe in sections to form a solid anti-wear layer, the ceramic inner wall is smooth and does not block the material, and the steps are less and the gaps are less, which can reduce the resistance of material transportation. Alumina ceramic pipe can isolate the contact between materials and steel parts so as to avoid the contamination of conveying materials. It is a kind of wear-resistant pipe widely used in pneumatic conveying.

The wear-resistant ceramic pipe extends the service life of the steel pipe, and the service life of the wear-resistant ceramic pipe can reach 1-5 years.

Wear-resistant ceramic pipe can solve the wear problem caused by pneumatic pipe conveying powder, slurry, particles, etc., and is the first choice for industrial wear resistance, impact resistance and corrosion resistance. Wear-resistant ceramic pipe is widely used in thermal power, iron and steel, coal, mining, chemical, lithium and other industries of pneumatic conveying anti-wear.