Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

Abrasion Resistant Alumina Ceramic Lined Pipe Installation Solution

Alumina ceramics characters of high hardness, high wear resistance, corrosion resistance, heat resistance. which overcome disadvantages of steel low hardness, poor wear resistance and ceramics poor toughness, therefore, ceramic lined pipes have comprehensive property of excellent wear resistance , hear resistance , corrosion resistance ,mechanical shock and thermal shock etc , it is the ideal pipeline of conveying sand, stone, coal ,ash, molten aluminum etc particles and corrosive medium.

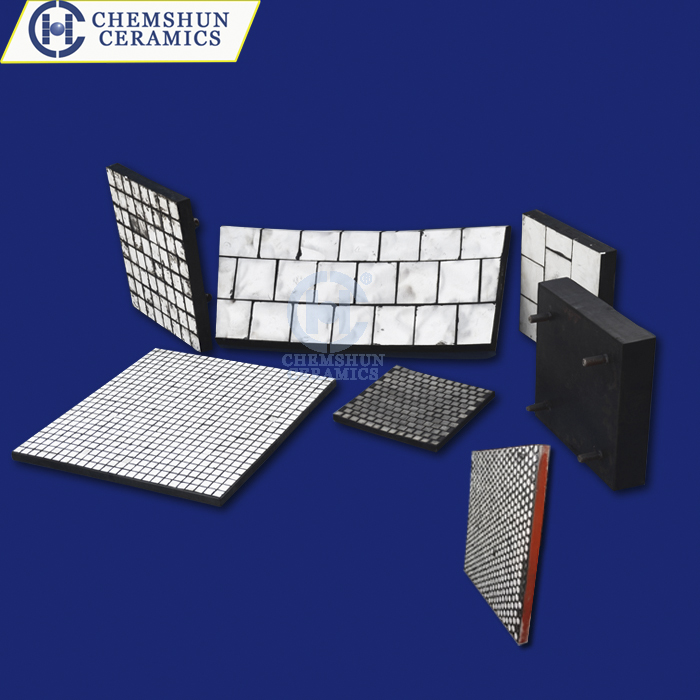

Wear resistant ceramic lined pipe can greatly solve pipeline wear damage problem. Chemshun Ceramics have many ceramic lined pipe design,produce, installation project. here different ceramic liner can be applied for steel pipe wear protection.

Option 1: wear resistant ceramic tile mat is directly installed.

Specifications: 10*10,15*15,17.5*17.5,20*20mm,etc.

Thickness of 2-6mm Paste into 150*150mm,300*300mm, 500*500mm and other dimensions.

Features: easy to install on the inside of the equipment, saving installation time and cost.

Option 2: The ceramic tube is used as ceramic liner to be directly installed in the pipe.

Specifications: 100-300mm,100-500mm in length.

Features: Smooth and easy to install, long service life.

Option 3: Rubber Ceramic Tile Liner.

Specifications: 300*300*63 mm, 500*500*30 mm, 300*300*25 mm or customized.

Features: Exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics.

Option 4: Installation with Slotted Ceramic Liner.

Specifications: 80*30/28.9*10mm or customized.

Special: Grooves and locks fit snugly on the walls of the equipment. Roundness is superior to other ceramics.

Solution 5: Installation with curved ceramic plates.

Specifications: 100*100*33mm or customized.

Special: The tight connection between the groove and the lock is better than other linings.

We accept custom orders.

If you want to know more product information, please feel free contact us(office@chemshun.com) and we'll afford you the most suitable product and best service!